Water wheel floating on water surface

A water surface and water wheel technology, applied in the field of water wheels, can solve the problems of being unsuitable for no drop, affecting the operation of the water wheel, etc., and achieve the effects of simple structure, less daily maintenance work, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

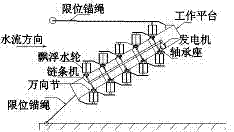

[0015] When the present invention is applied on the power generation ship, the installation method with other accessories is as follows:

[0016] The water wheel floating on the water passes through the bearing seat on the power generation ship to support the working platform, and then drives the sprocket mechanism to drive the generator set to generate electricity.

[0017] The working principle of the present invention is as follows:

[0018] The interior of the water wheel floating on the water is a closed cavity, and the blades can also be made into a cavity. The buoyancy of the water wheel is much greater than its own gravity, and the intermediate transmission shaft can be lifted from the water surface. When the transmission shaft is lifted by the bearing seat on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com