Advancing compensation type cable-stayed bridge overall cable-replacement equipment and cable-replacement method using equipment

A cable-stayed bridge and compensation technology, which is applied in the direction of cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of increased tensile stress of the main girder, increased cracking, damage, etc., and achieve the effect of improving safety and avoiding diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

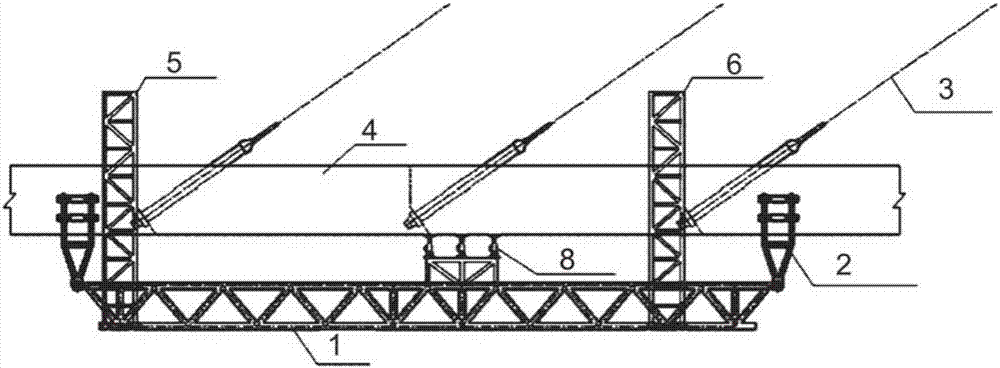

[0065] A concrete cable-stayed bridge with double-sided rib girders as the main girder has a bridge width of 23 meters, a girder height of 2 meters, and a distance of 8 m between the cables on the girder. The stay cables are anchored to the double-sided main girders.

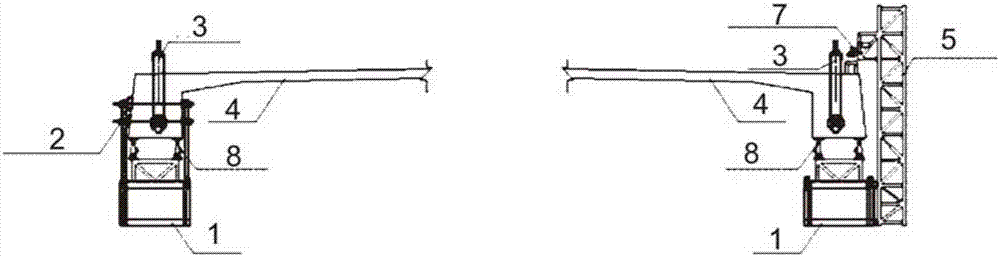

[0066] Assemble the longitudinal track and traction system on the bridge deck, install the vertical ladder, the main truss, and the fixing device for the main girder, and install jacking jacks on the main truss. The main truss is fixed on the vertical ladder in advance; the double-ribbed concrete main girder is horizontally opened and its internal prestressed pipe is avoided, the tie rod of the fixing device is pierced, and the tension screw is fixed, and the weight of the main truss is transferred from the ladder to the fixed device.

[0067] When starting to replace the cables, first touch the anchor head of the tension end of the cable to be replaced to obtain the initial tension; the old cables are unloaded ...

example 2

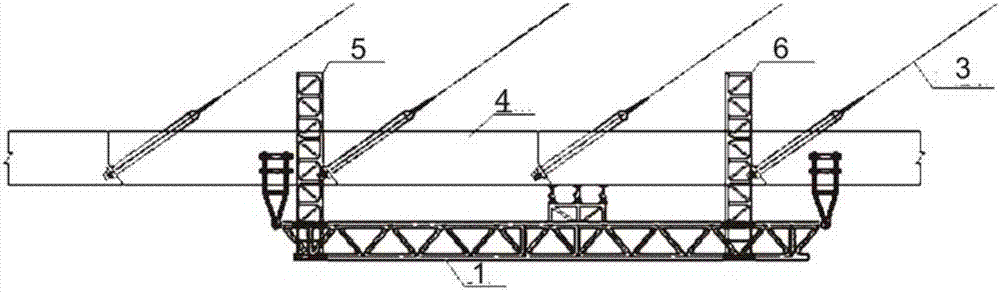

[0070] For a concrete cable-stayed bridge with a single-box multi-chamber closed box girder as the main girder, the stay cables are anchored to the solid block of the side box, and jacking jacks are arranged after the bottom of the side box girder is leveled. The rest of the cable replacement process is the same as in Example 1.

example 3

[0072] For a concrete cable-stayed bridge with a single-box multi-chamber closed box girder as the main girder, the cable-stayed cables are anchored in the middle box. Jacking jacks are arranged in the mid-span of the channel, and the rest of the rope replacement process is the same as that of the example.

[0073] Using the equipment and method of the present invention for cable replacement can synchronously compensate and increase the compressive stress at the bottom of the concrete beam in the cable replacement area, avoiding damage to the bottom edge of the cable replacement process due to tensile stress, improving safety, and ensuring that no damage is caused. It is possible to replace the stay cables or long cables in areas with small compressive stress reserves of concrete cable-stayed bridges while carrying traffic. And the equipment process of the present invention is simple, is easy to operate, and cost is low, that is, the working platform is also a cable unloading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com