Carbon source recycling based excess sludge treatment process

A technology for excess sludge and treatment process, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of low organic acid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0018] In order to promote the accumulation of organic acids and promote the reuse of carbon sources, the present invention provides a residual sludge treatment process based on the reuse of carbon sources, including the following process steps:

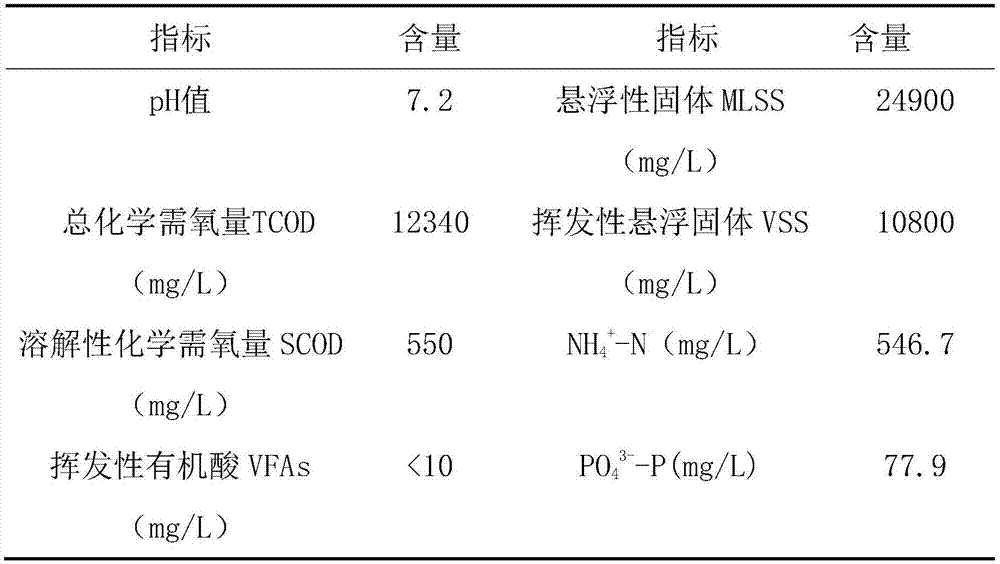

[0019] (1) Hot alkaline pretreatment of the remaining sludge: The retrieved fresh sludge is left to stand for concentration for 24 hours and then the supernatant is removed. The properties of the fresh sludge are as follows figure 1 As shown, the concentration of SCOD is 550 mg / L and the concentration of VFAs is less than 10 mg / L. The pH value of the sludge was adjusted to 10 with 5mol / L NaOH, and it was placed in a heating device at 90°C for constant temperature heating for hot alkaline pretreatment for 2h, and stirring was continued.

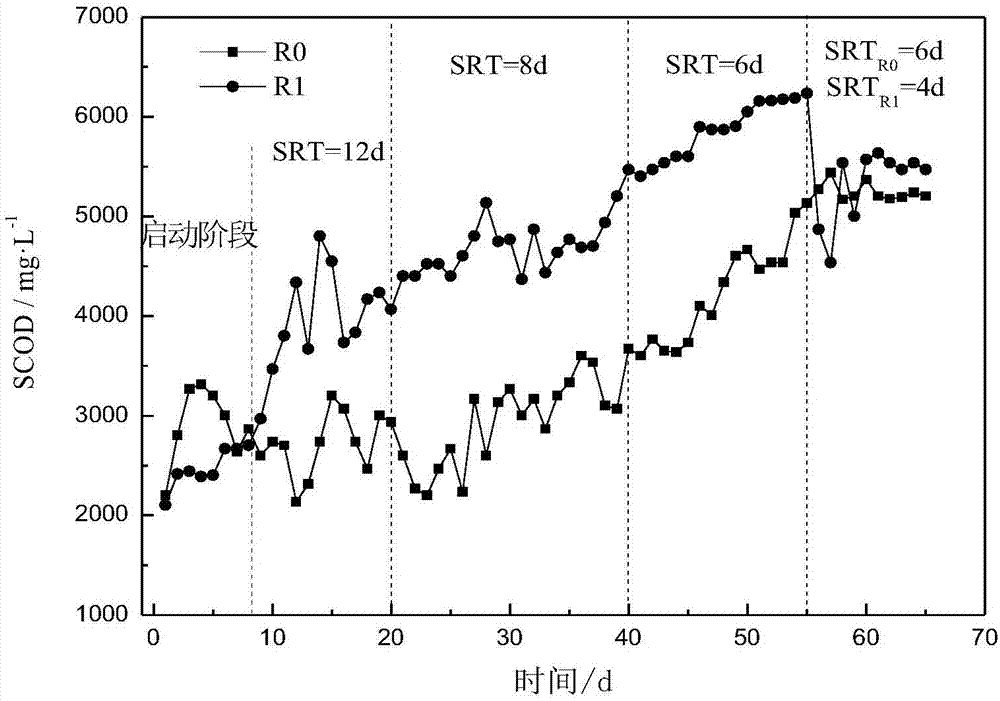

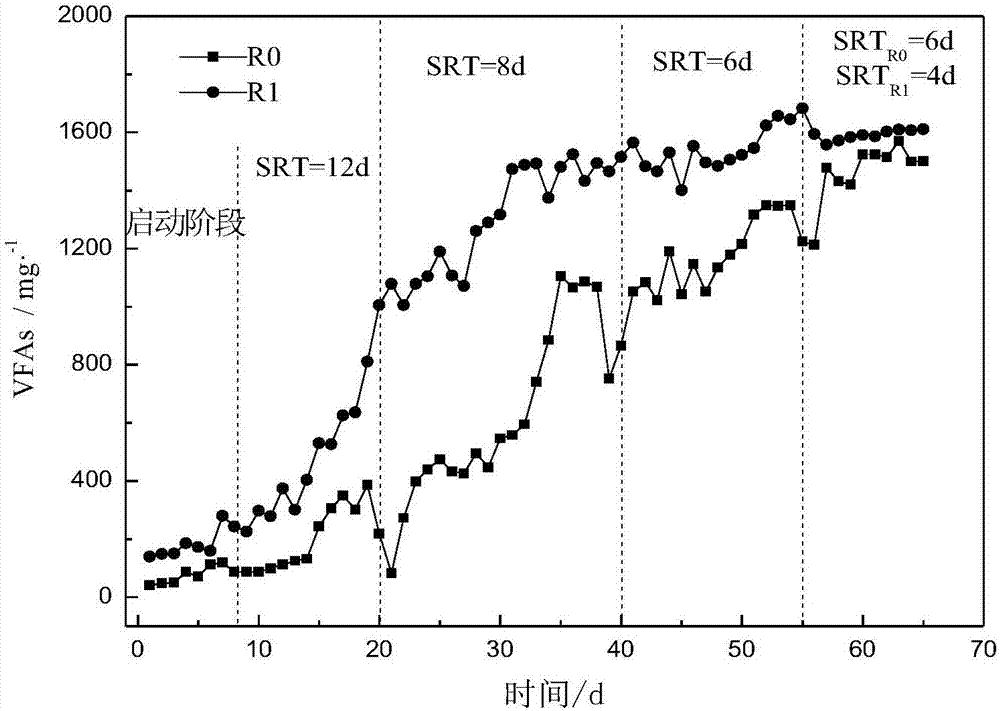

[0020] (2) Acid start-up of the reactor: pump the sludge pretreated with hot alkali ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com