A permeable reactive wall composite material for groundwater chlorine-containing nitroaromatic pollution restoration and preparation method thereof

A technology for nitroaromatics and pollution remediation, applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of short effective time and poor removal effect, achieve long removal time, improve utilization rate, The effect of improving respiratory metabolic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

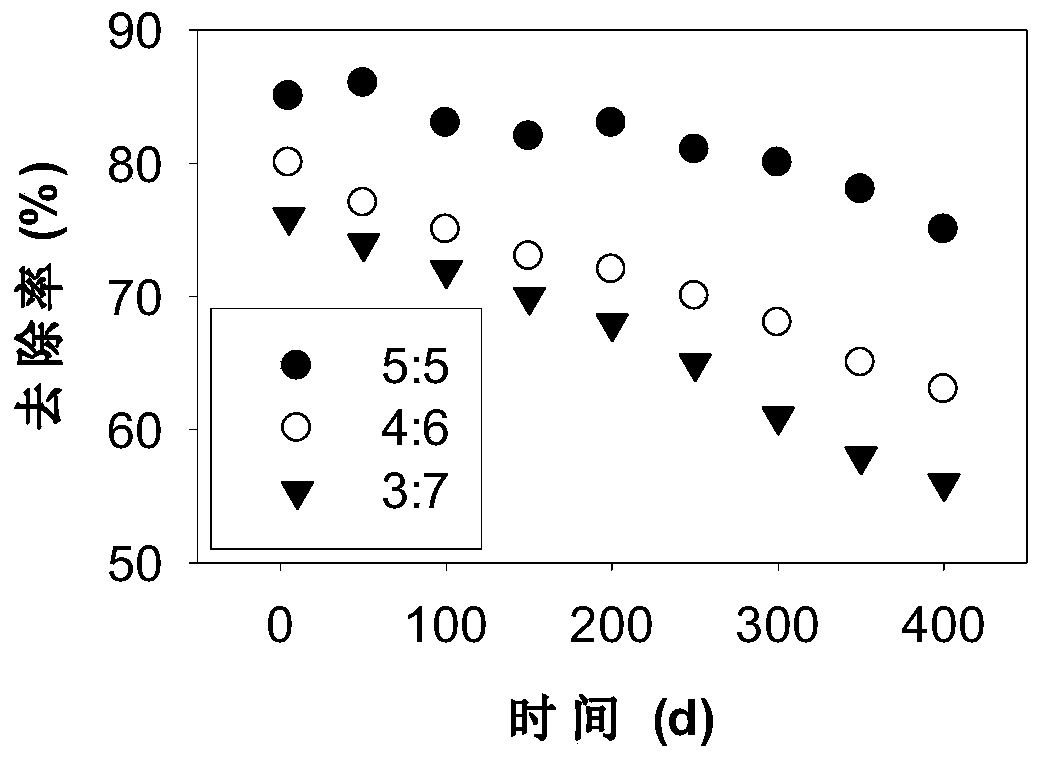

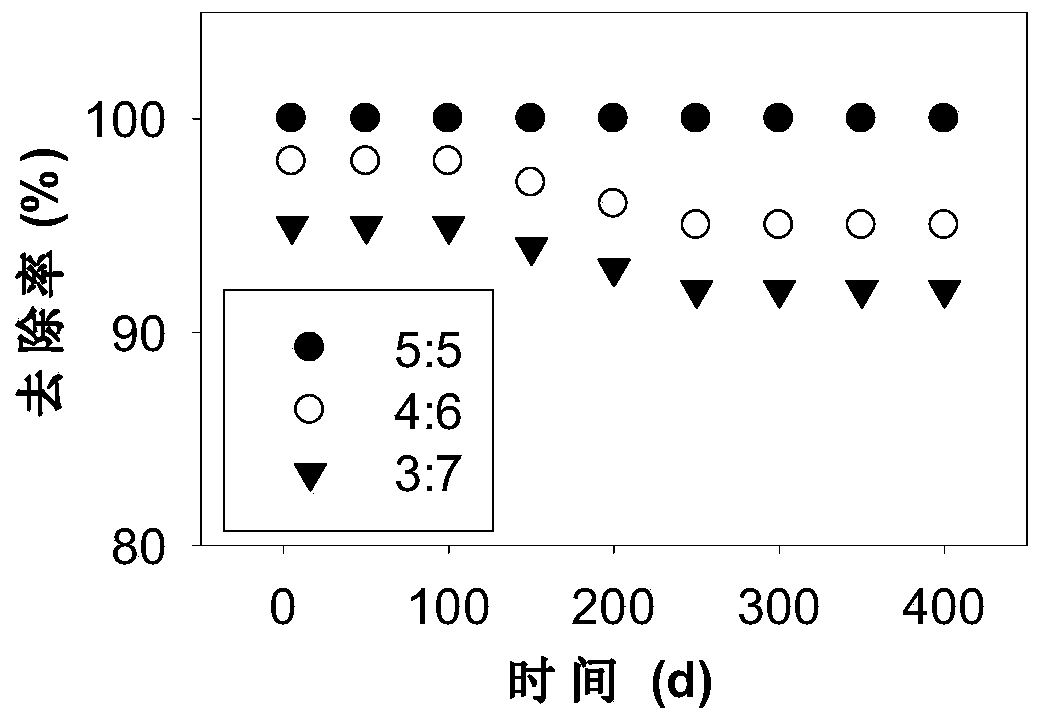

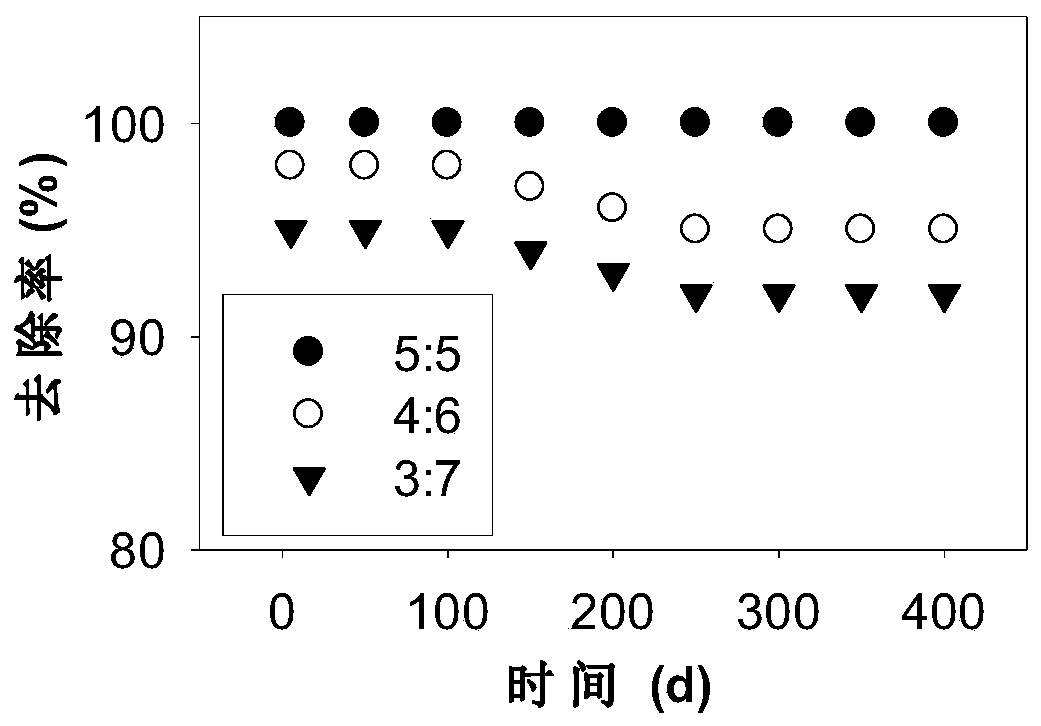

[0049] The permeable reactive wall composite material used for the restoration of chlorine-containing nitroaromatics pollution in groundwater in this embodiment 1 includes an inner core, a filling layer and an outer shell, the inner core is attapulgite, and the filling layer is composed of the following components in mass percentage : Reducing agent Fe-Cu bimetallic 10.4%, mainly to create a strong reducing environment for the removal of chlorine-containing and nitro-aromatic hydrocarbons, the carbon release raw material is coconut shell biochar 35.1%, mainly to ensure the carbon source required for microbial growth; plasticity The bonding raw material attapulgite is 26%, mainly to bond all raw materials together and maintain a certain hardness; the high-permeability raw material diatomite is 10.8%, mainly to provide natural channels for the growth and reproduction of microorganisms, and to ensure that the composite material can slow down. Reducing agent and carbon source; the ...

Embodiment 2

[0068] The permeable reactive wall composite material used for the restoration of chlorine-containing nitroaromatics pollution in groundwater in this embodiment 2 is basically the same as in embodiment 1, except that the filling layer is composed of the following components in mass percentage: reducing agent Fe- Cu bimetal is 12%, carbon release raw material is coconut shell biochar 34%, plastic bonding raw material attapulgite 23%, high permeability raw material diatomite 9.5%, binder (mixture of sodium alginate and water) was 21.5%. The shell is made up of the following components in mass percentage: 11% of high-permeability raw material diatomite, 66.7% of plastic bonding raw material (20.9% of ordinary Portland cement, 45.8% of attapulgite), binder (seaweed A mixture of sodium bicarbonate and water) was 22.3%. The coconut shell biochar used in the composite functional material of this embodiment is 150 mesh, the attapulgite and diatomite are 170 mesh, and the cement is 90...

Embodiment 3

[0073] The permeable reactive wall composite material used for the restoration of chlorine-containing nitroaromatics pollution in groundwater in this embodiment 3 is basically the same as in embodiment 1, except that the filling layer is composed of the following components in mass percentage: reducing agent Fe- Cu bimetal is 15.3%, carbon release raw material is coconut shell biochar 33.3%, plastic bonding raw material attapulgite 21.7%, high permeability raw material diatomite 9%, binder (mixture of sodium alginate and water) was 20.7%. The shell is made up of the following components in mass percentage: 11.9% of high-permeability raw material diatomite, 67% of plastic bonding raw material (23.8% of ordinary Portland cement, 43.2% of attapulgite), binder (seaweed A mixture of sodium bicarbonate and water) was 21.1%. The coconut shell biochar, attapulgite and diatomite used in the composite functional material of this embodiment are 200 mesh, and the cement is 100 mesh.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com