Correcting tool and correcting method for rod length parameter of industrial robot

A technology of industrial robots and calibration methods, applied in the field of industrial robots, can solve the problems of positioning accuracy and repetition accuracy error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

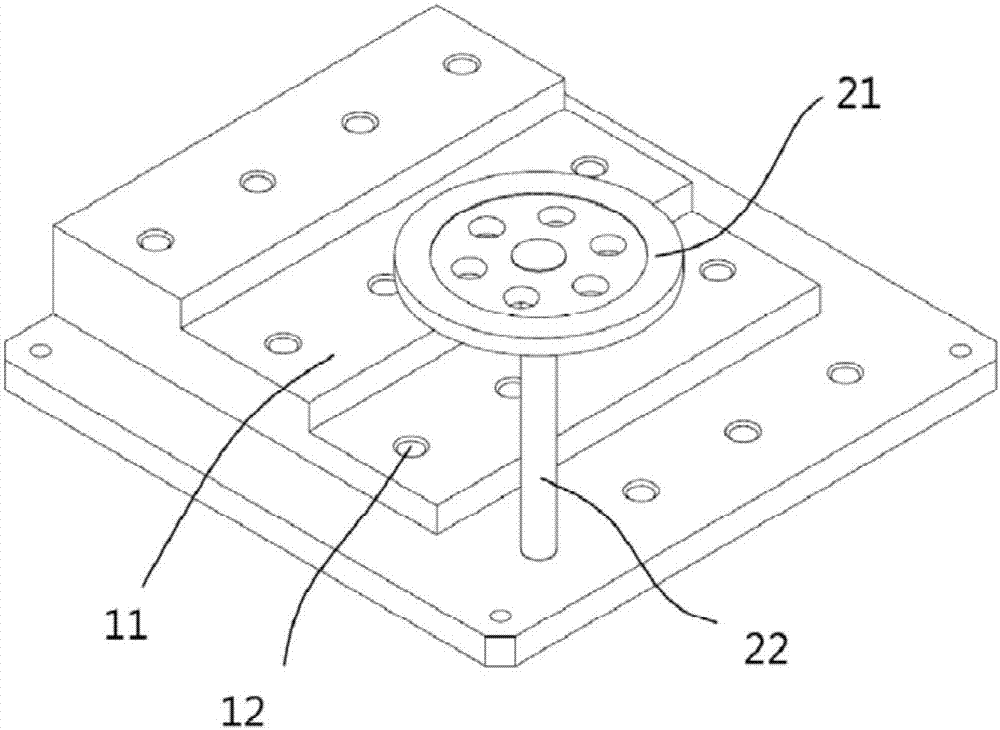

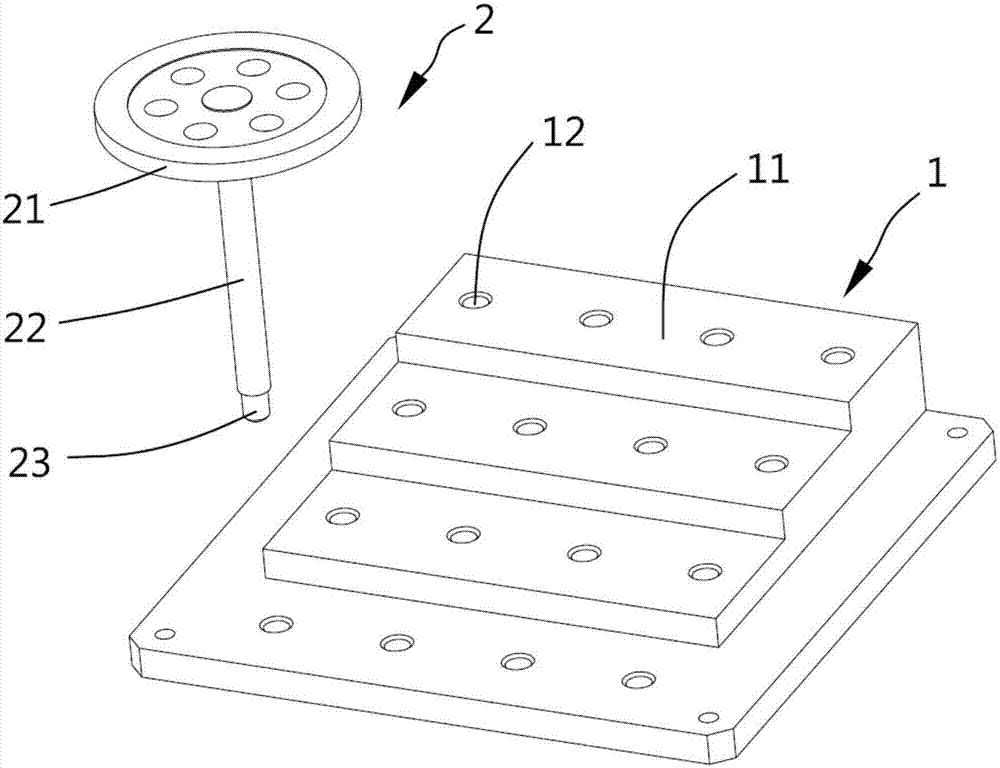

[0036] refer to figure 1 and figure 2 As shown, the present embodiment is a calibration tool for the rod length parameters of an industrial robot, including a step plate and a nail plate, and the step plate is provided with four steps of the same height, each layer is 10mm in height, and the length and width of the bottom layer are the same. 200mm, there are four round holes on each step, a total of 16, all the round holes form a 4×4 matrix arrangement, the distance between the round holes is 40mm, the diameter of the round holes is 8mm+0.1mm, the depth The diameter is 10mm, and the round hole is designed to match the thin rod of the nail plate. There are also four mounting screw holes at the four corners of the bottom layer.

[0037] The nail plate includes a flange part, a rod part and a thin rod part. The axis of the nail plate rod part coincides with the axis of the flange. The length of the rod is 100mm and the diameter is 10mm. On the end flange of an industrial robot...

Embodiment 2

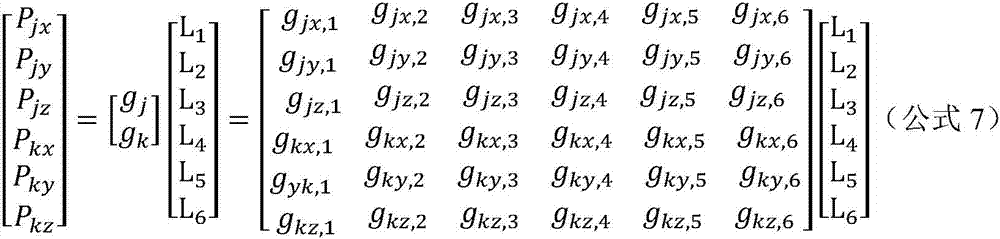

[0039] This embodiment is a method for correcting the pole length parameters of an industrial robot. This method is implemented on the basis of the calibration tool in Embodiment 1. It measures the pole length of an industrial robot with six axes. It has six poles Long and six joints, the rods and joints are numbered from the side near the base in this embodiment.

[0040] The correction method includes the following steps:

[0041]S1. Install the step plate and the nail plate, and align the origin of the modeling of the industrial robot. When installing, one side of the outer edge of the step plate is perpendicular to the X axis of the world coordinate system of the industrial robot, and forms an angle of 30 degrees with the Y axis. , fix the flange part of the nail plate to the end flange of the industrial robot.

[0042] S2. Set up the system, including controlling the driver to enable the soft floating function, limiting the current amplitude, and allowing the tracking po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com