Shearing knife with bionic curved surface

A technology of shearing knives and curved surfaces, used in shearing devices, tools for shearing machines, metal processing equipment, etc. The effect of improving the characteristics, increasing the number of times of use, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

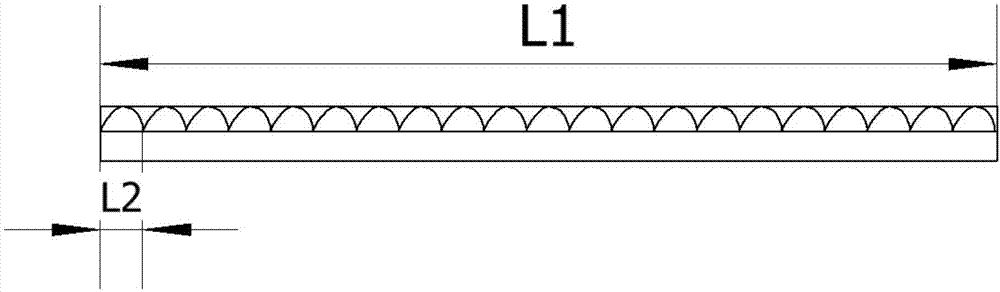

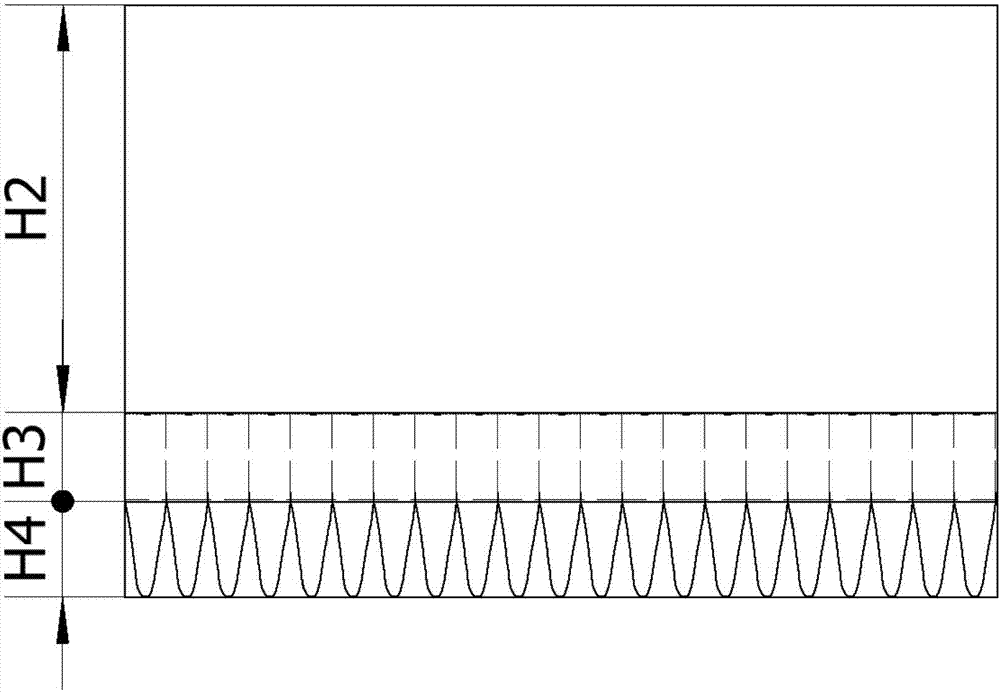

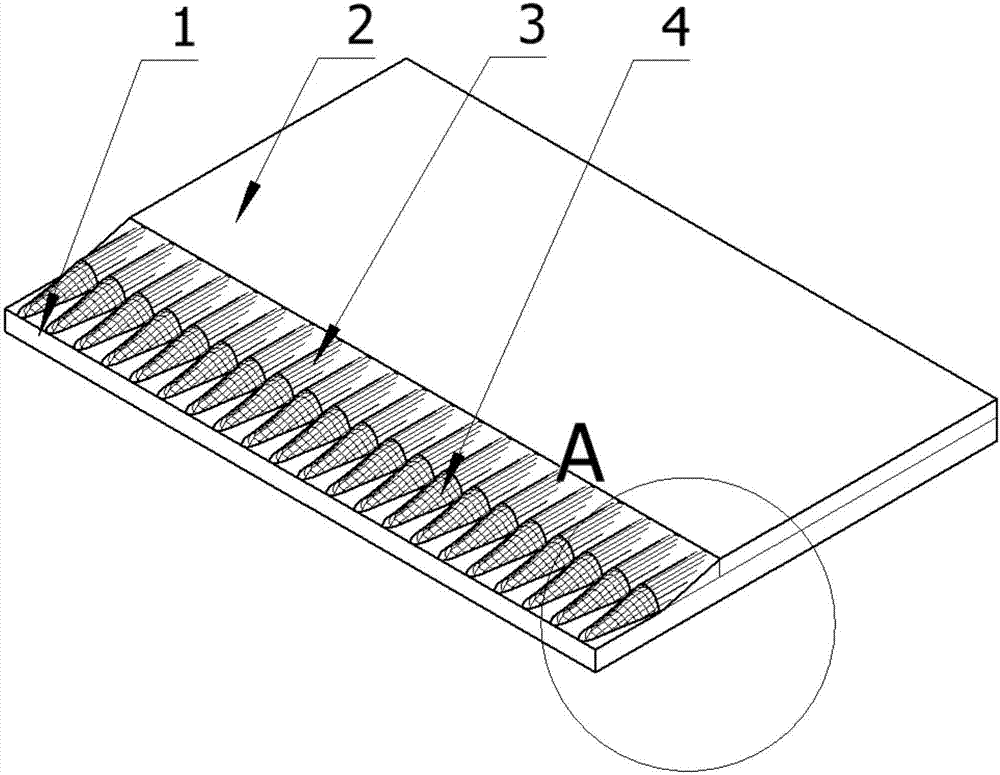

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, this embodiment includes a knife base 1, a knife back 2, a transition section 3 and a knife tip 4, the transition section 3 is composed of a bionic semi-cylinder 5 and a triangular prism 6, and the knife base 1 is used as the back of the entire bionic shearing knife to carry the knife back 2. The transition section 3 and the knife tip 4; the knife back 2 is located on the surface of the knife base 1, and the bottom surface and two sides of the knife back 2 coincide with the bottom surface and the side surfaces of the knife base 1; the transition section 3 is a bionic half cylinder 5 and a triangular prism 6 structure Assembled body, the bottom of triangular prism 6 coincides with the top of knife back section, and the length and width of bottom surface are identical with knife back section, and the upper part of semi-bionic cylinder 5 coincides with triangular prism body.

[0031] T...

Embodiment 2

[0044] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, this embodiment includes a knife base 1, a knife back 2, a transition section 3 and a knife tip 4, the transition section 3 is composed of a bionic semi-cylinder 5 and a triangular prism 6, and the knife base 1 is used as the back of the entire bionic shearing knife to carry the knife back 2. The transition section 3 and the knife tip 4; the knife back 2 is located on the surface of the knife base 1, and the bottom surface and two sides of the knife back 2 coincide with the bottom surface and the side surfaces of the knife base 1; the transition section 3 is a bionic semi-cylindrical body 5 and a triangular prism 6 Structural composite body, the bottom of triangular prism 6 coincides with the top of knife back section, and the length and width of triangular prism 6 bases are identical with knife back section, and the upper part of semi-bionic cylinder 5 coincides with triangular pris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com