Circle correcting device for welded steel pipe

A technology for welding steel pipes and adjusting the circle, which is applied in the field of mechanical equipment, can solve the problems that the outer circle and the inner circle cannot be adjusted at the same time, low efficiency, inconvenience, etc., and achieve the effect of good circle adjustment and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

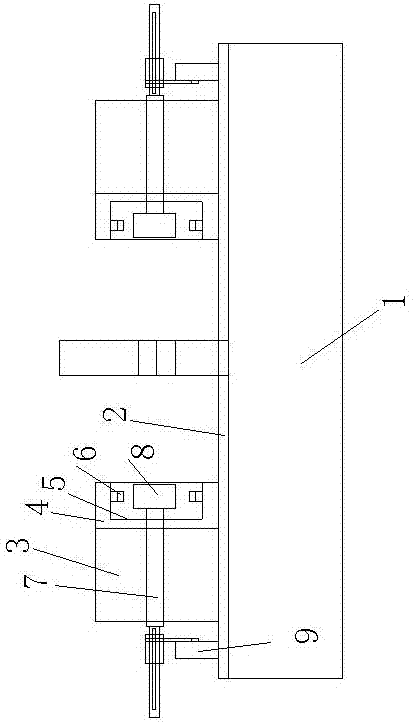

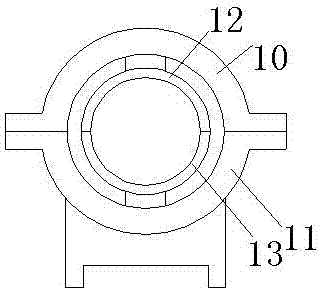

[0014] As shown in the figure, the welded steel pipe rounding device of the present invention includes a frame 1, two steel pipe end fixing devices are arranged symmetrically on the frame 1, and an outer circle rounding mold is arranged between the two steel pipe end fixing devices , the steel pipe end fixing device and the outer circle calibration mold are all arranged on the guide rail 2 of the frame 1, and can move along the guide rail 2, and the steel pipe end fixing device includes a base 3 and a fixing head 4, The fixed head 4 is rotatably connected to one side of the base 3, a groove 5 is set in the middle of the fixed head 4, and a plurality of retractable arc-shaped pressure plates 6 are evenly spaced on the inner side wall of the groove 5, and a wire is installed in the middle of the groove 5. Bar 7, leading screw 7 one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com