Garbage dump platform for subarea unloading and application method and building method thereof

A technology for unloading platforms and garbage dumps, which is used in construction, solid waste removal, roads, etc., can solve the problems of difficult driving of garbage trucks and bulldozers, high moisture content, high porosity, and long garbage tilting distance. The effect of building construction time, speeding up the turnover rate, and reducing the platform area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

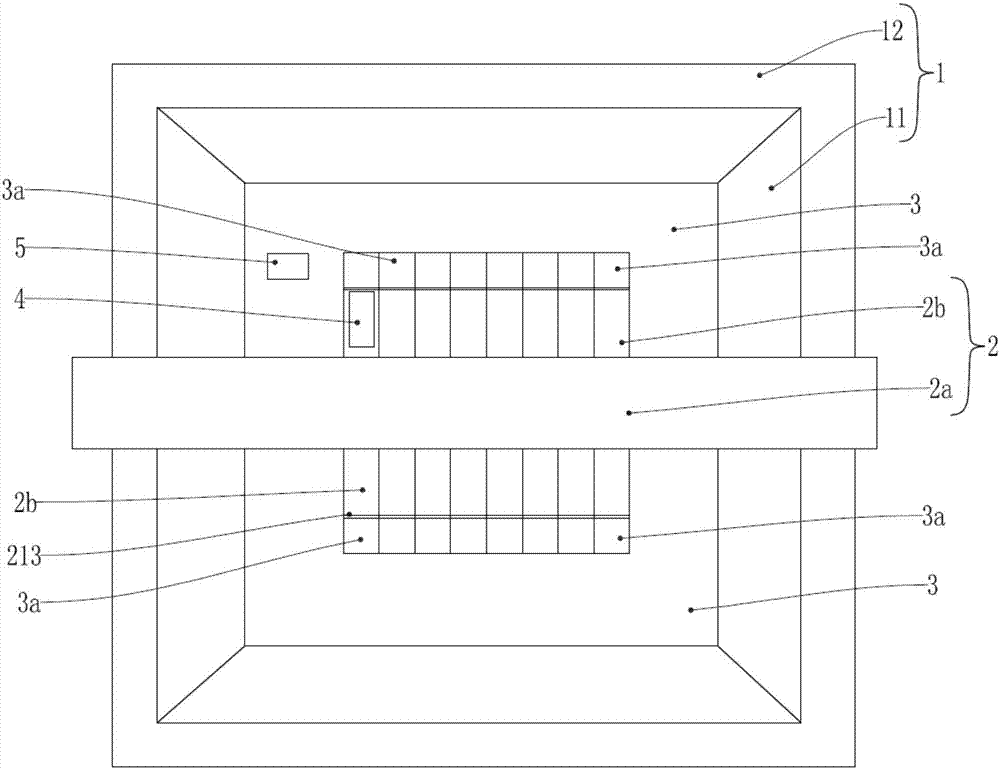

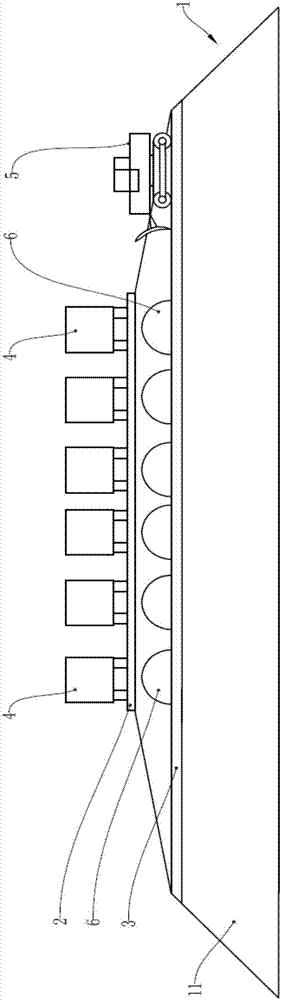

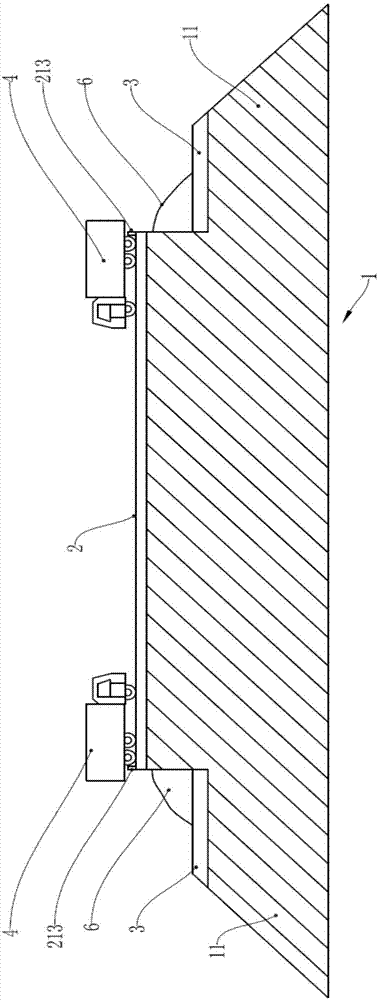

[0035] The garbage dump platform of the partition unloading of the present embodiment, such as Figure 1 to Figure 3 As shown, it includes a garbage base 1, an unloading platform 2 and a pushing platform 3. The unloading platform 2 is arranged on the top of the garbage base 1, and the pushing platform 3 is arranged on the garbage base 1 and surrounds the unloading platform 2. Edge, the pushing platform 3 is arranged below the unloading platform 2; the unloading platform 2 is provided with a conveying path 2a and a plurality of unloading stations 2b, and a plurality of the unloading stations are arranged on both sides of the conveying path 2a 2b, the unloading station 2b extends to the edge of the unloading platform 2 .

[0036] The garbage dump platform for partition unloading sets the unloading pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com