A device and method for preventing scaling of milk of lime in smelting desulfurization system

A desulfurization system and lime milk technology are applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., which can solve problems such as lime milk sticking, and achieve the effect of improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

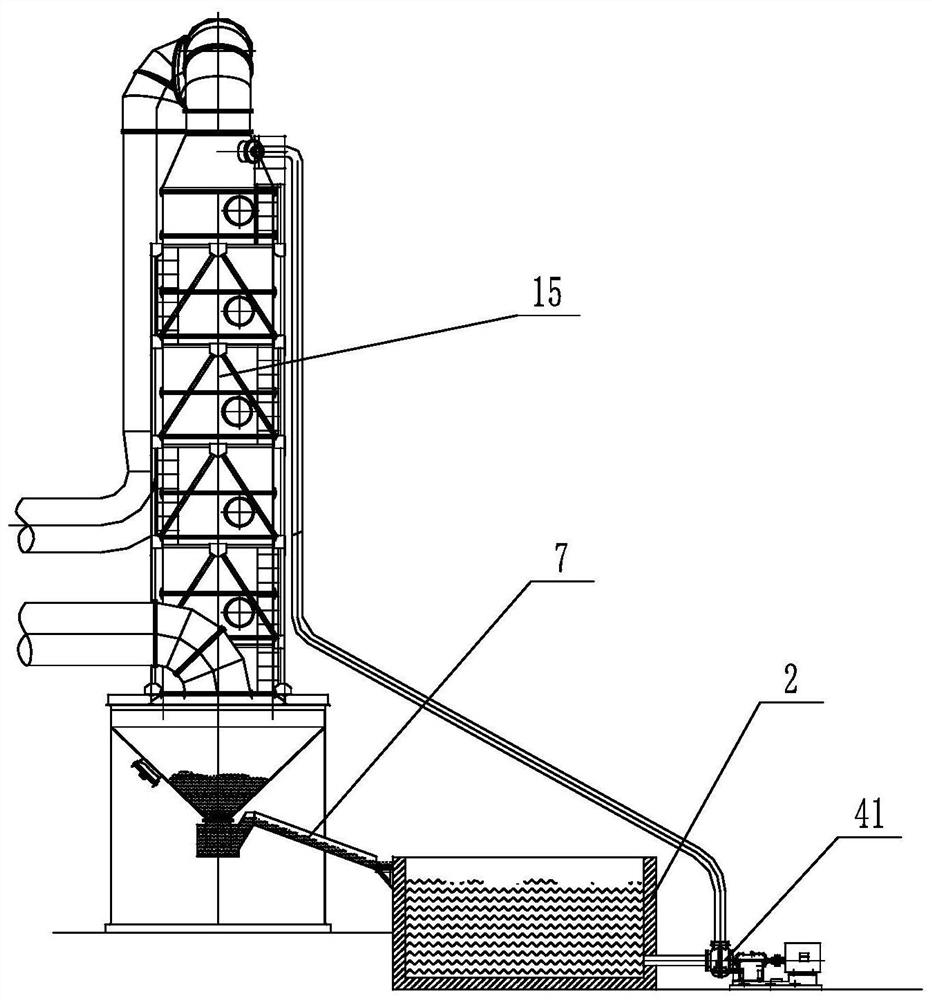

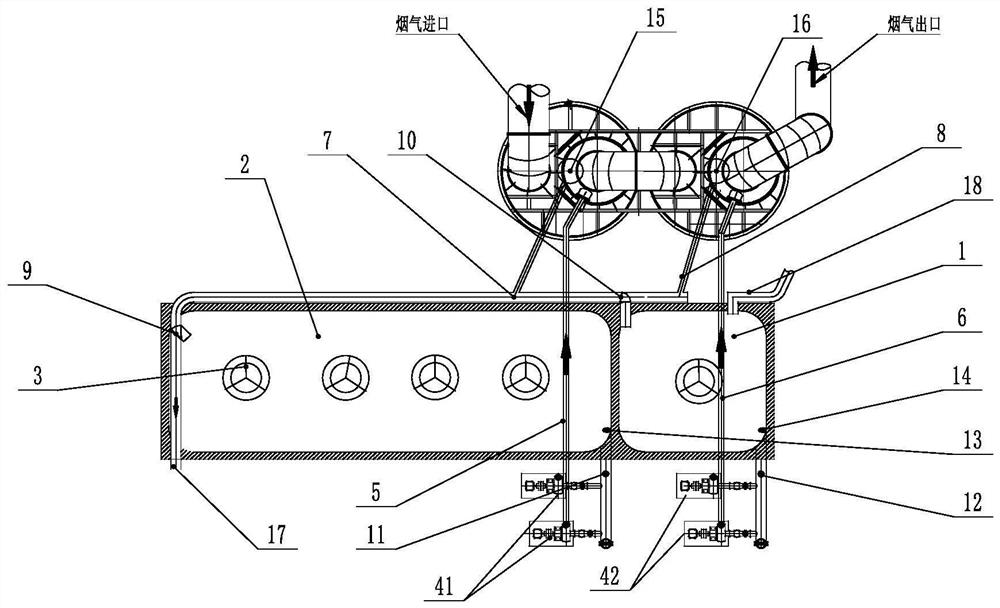

[0016] A specific implementation method of a device for preventing scaling of milk of lime in the smelting desulfurization system will be described below in conjunction with the accompanying drawings.

[0017] A device for preventing scaling of lime milk in a smelting desulfurization system, comprising a raw slurry tank 1, an aeration tank 2, a mixer 3, a slurry pump 4, a first slurry pump pipeline 5, a second slurry pump pipeline 6, a first Lime chute 7, second lime chute 8, first lime liquid diverter valve 9, second lime liquid diverter valve 10, first PH value automatic detection device 11, second PH value automatic detection device 12, first water level monitor 13 , The second water level monitor 14.

[0018] The first slurry pump 41 pumps the milk of lime in the aeration tank 2 to the first reaction tower 15 of the DS multiple reactor through the first slurry pump pipeline 5. A lime chute 7 circulates into the aeration tank.

[0019] A second slurry pump 42 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com