Dough mixer

A dough mixer and machine body technology, which is applied in the direction of dough mixer, structural components of mixing/kneading machinery, horizontal installation tools for mixing/kneading, etc. It can solve the problems of greatly affecting the taste of finished products, reducing the degree of sugar dispersion and melting, etc. problems, achieve the effect of saving mixing time, delicate taste and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

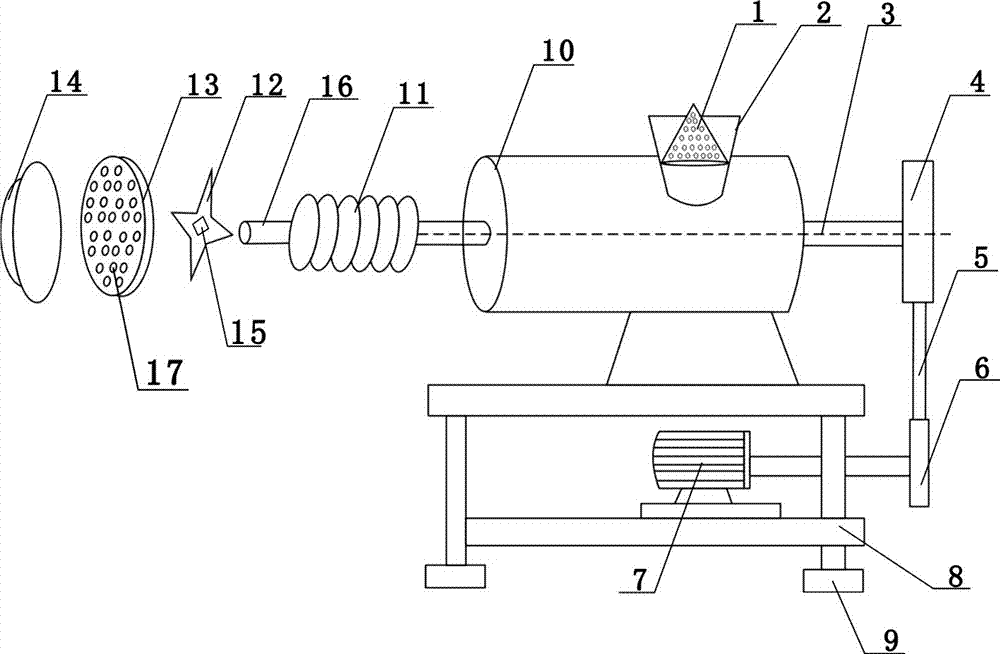

[0015] Such as figure 1 As shown, a dough mixer includes a body 10 with a feed hopper 2 on the body 10, a central shaft 3 is arranged in the cavity of the body 10, an auger 11 is installed at one end of the central shaft 3, and an auger 11 is provided at the end of the auger 11 The square shaft 16, the square shaft 16 is inserted into the square hole 15 of the cross reamer 12, the central hole of the disc cutter 13 is inserted into the cylindrical end of the end of the square shaft 16, the disc cutter 13 passes through the fixed ring 14, the fixed screw The cap is fixed to the discharge port of the body 10. The other end of the central shaft 3 extends out of the cover of the body 10 to connect with the flywheel 4, which is connected to the driving device. The driving device includes a motor 7, a pulley 6, and a belt 5. The output shaft of the motor 7 is sleeved with the pulley 6, and the pulley 6 is connected to the flywheel 4 through the belt 5.

[0016] The feed hopper 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com