Lamp installation method suitable for industrial hot workshop factory building

A lamp installation and workshop technology, which is applied in the direction of lighting devices, lighting auxiliary devices, lighting and heating equipment, etc., can solve the problems of lighting lamp installation, maintenance and cleaning difficulties, and achieve the goal of solving installation and maintenance problems and improving work efficiency and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

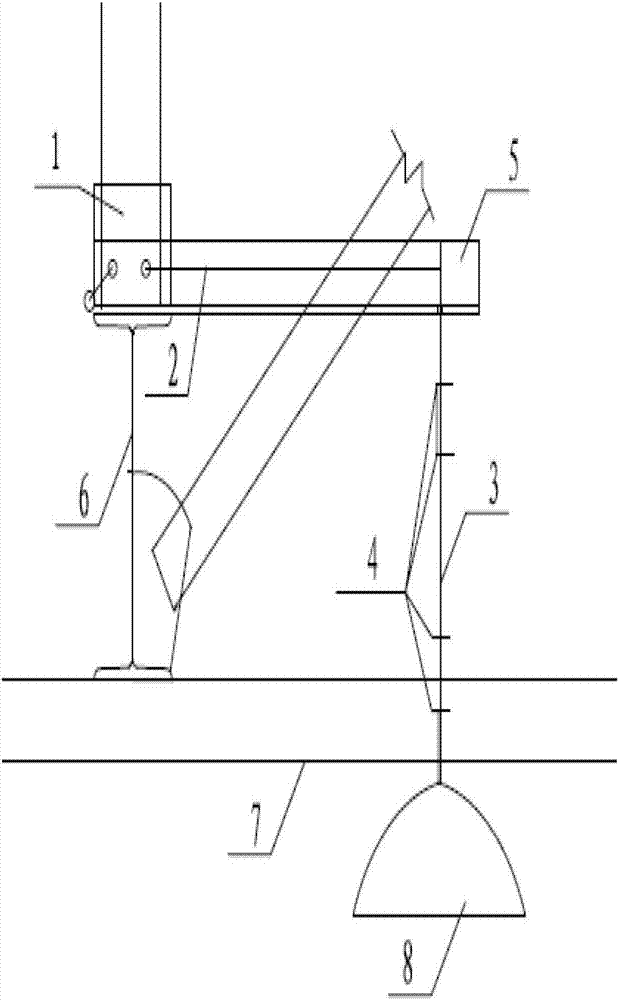

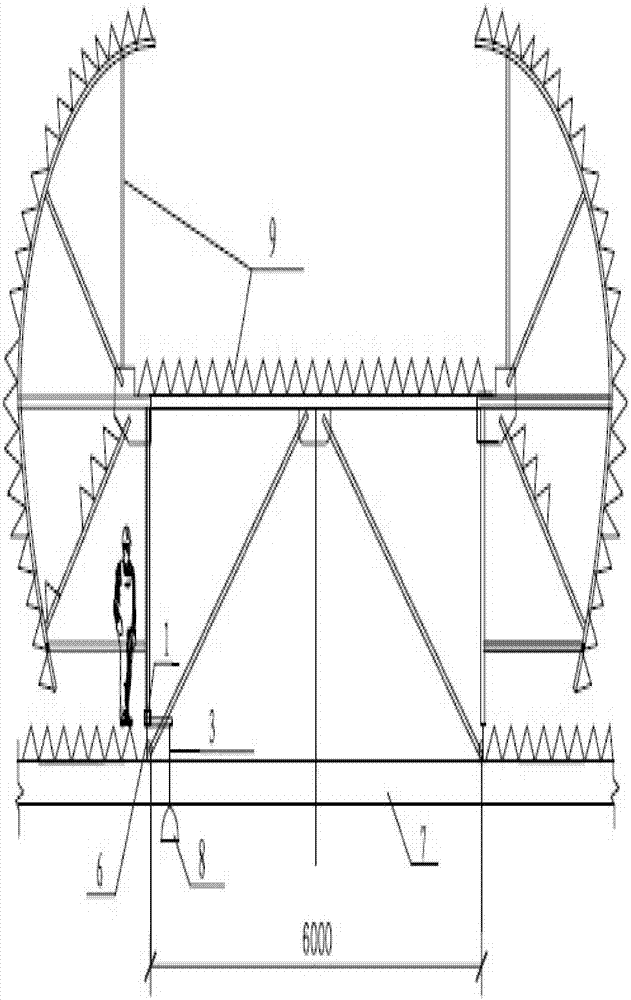

[0015] 1. Use the angle steel bracket 2 to fix the lighting fixture 8 on the skylight frame 6, and use the steel wire rope 3 for hanging the lighting fixture to hang the lighting fixture 8;

[0016] 2. Use the space between the ventilation window windshield and the skylight frame 6 as an installation and maintenance platform.

[0017] When overhauling the lighting fixture 8, the lighting fixture 8 is lifted with the steel wire rope 3 for hanging the lighting fixture, so that work such as overhauling and cleaning can be completed conveniently and quickly.

[0018] Among them, the diameter of the steel wire rope 3 for hanging lamps is 3 mm, and the weight of the lighting lamps 8 is 7.5 kg.

Embodiment 2

[0020] 1. Use the angle steel bracket 2 to fix the lighting fixture 8 on the skylight frame 6, and use the steel wire rope 3 for hanging the lighting fixture to hang the lighting fixture 8;

[0021] 2. Use the space between the ventilation window windshield and the skylight frame 6 as an installation and maintenance platform.

[0022] When overhauling the lighting fixture 8, the lighting fixture 8 is lifted with the steel wire rope 3 for hanging the lighting fixture, so that work such as overhauling and cleaning can be completed conveniently and quickly.

[0023] Among them, the steel wire rope 3 for hanging lamps has a diameter of 4.5 mm, and the lighting lamps 8 weigh 25 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com