Automatic assembly machine for panel socket

A technology for assembly machines and sockets, which is applied to the assembly/disassembly of contacts, electrical components, circuits, etc., and can solve problems such as increasing labor costs, increasing workload, and reducing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

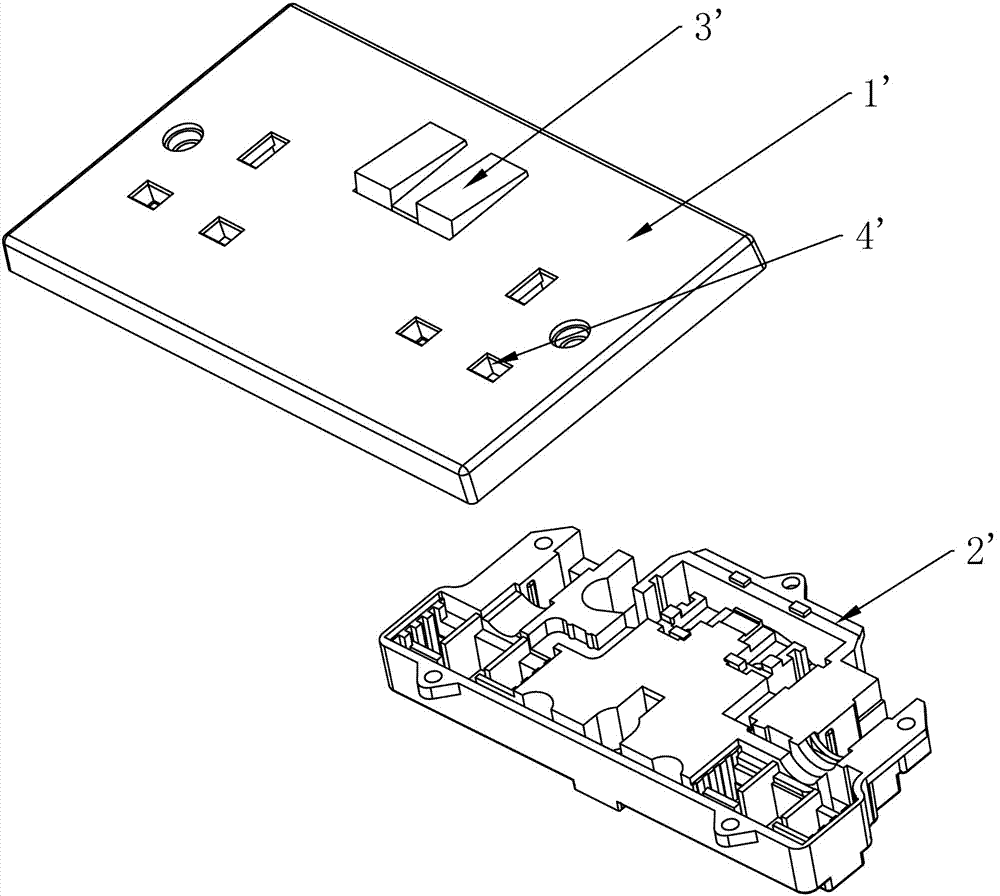

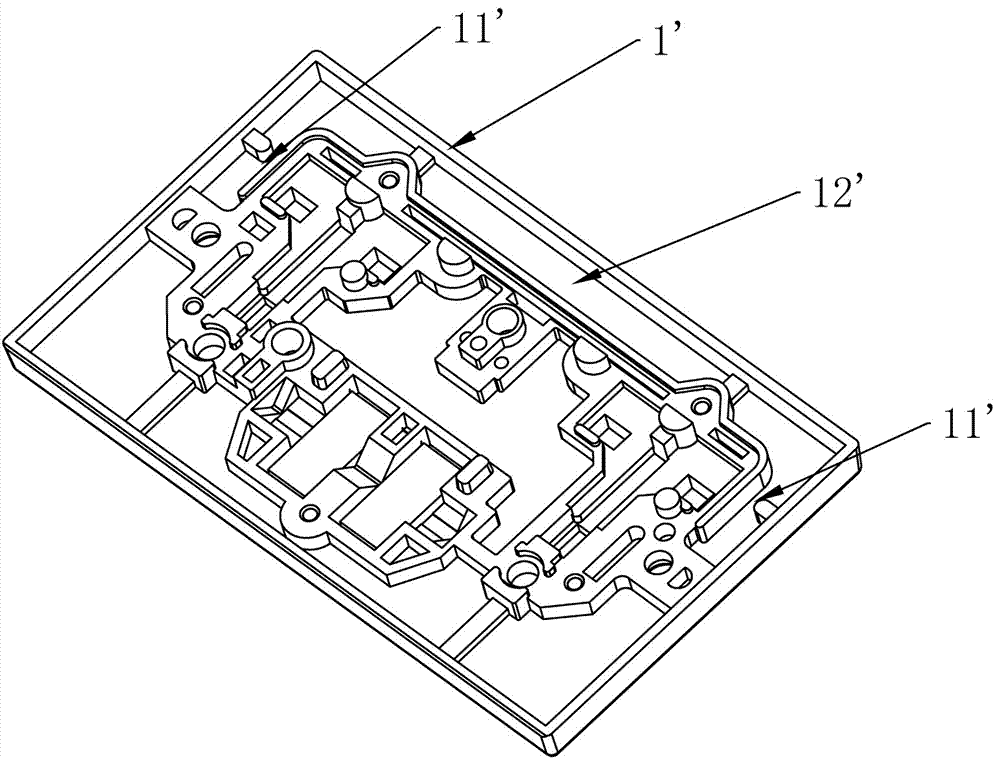

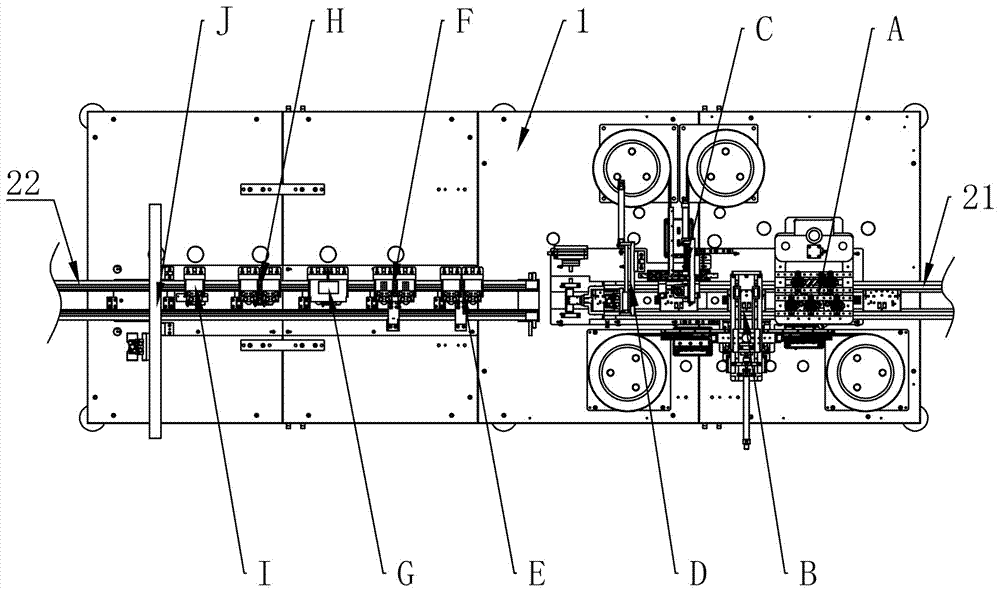

[0056] Such as Figure 3 to Figure 18 A panel socket automatic assembly machine shown includes a frame 1, a main control device and a first feeding conveyor belt 21 and a second feeding conveyor belt 22 arranged on the frame 1; The feeding direction of belt 21 is provided with fixed screw installation station A, wall screw installation station B, screw cap installation station C and first screening station D in sequence; In the feeding direction, there are power-off test station E, power-on test station F, plug-in force test station G, high-voltage test station H, safety door test station I and the second screening station J; rack 1 A material transfer mechanism 8 for moving the workpiece from the first feeding conveyor belt 21 to the second feeding conveyor belt 22 is also provided.

[0057] When working, the bottom cover assembly is placed on the back of the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com