Reinforcing steel bar and concrete pull-out testing device capable of eliminating high-temperature influences

A technology for drawing test and concrete, applied in the direction of measuring device, using mechanical device, applying stable tension/pressure to test material strength, etc., can solve the problem that the temperature influence of steel bar and concrete specimen under high temperature cannot be eliminated, and achieve processing Easy to manufacture, easy to control, easy to assemble and install, and eliminate the effect of temperature influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

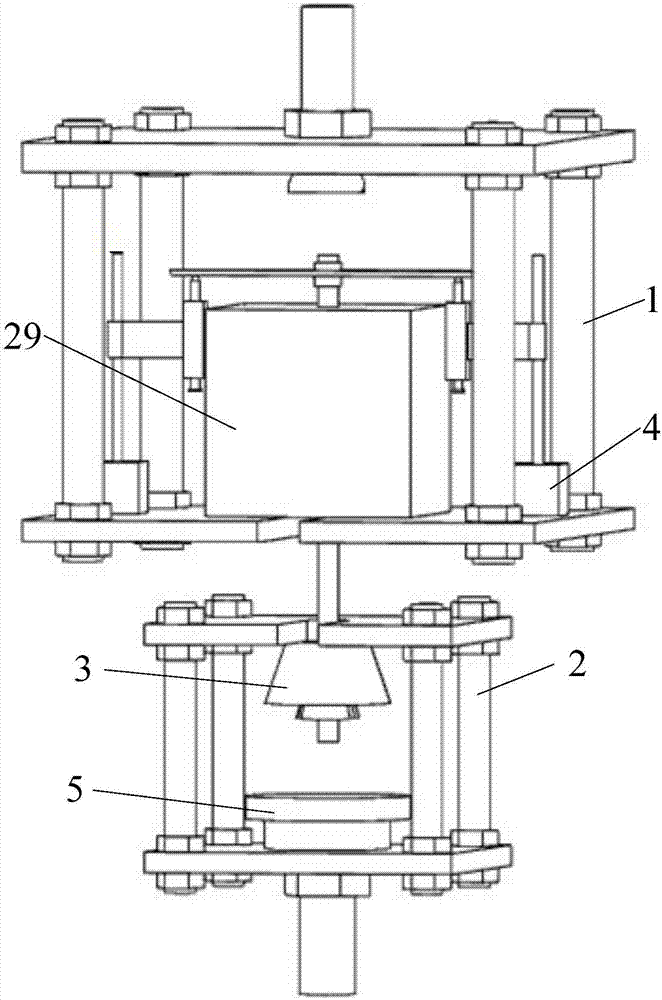

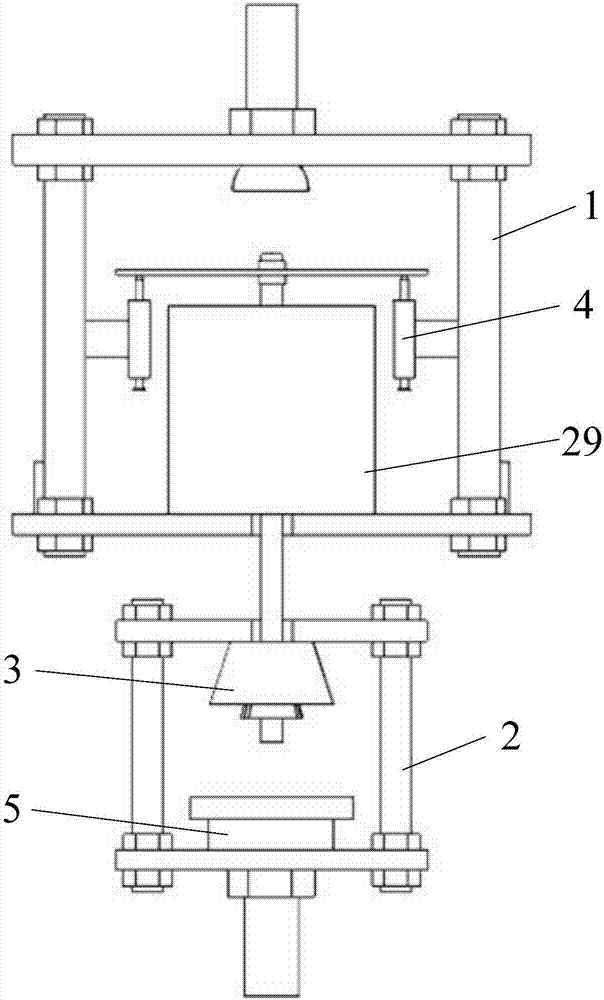

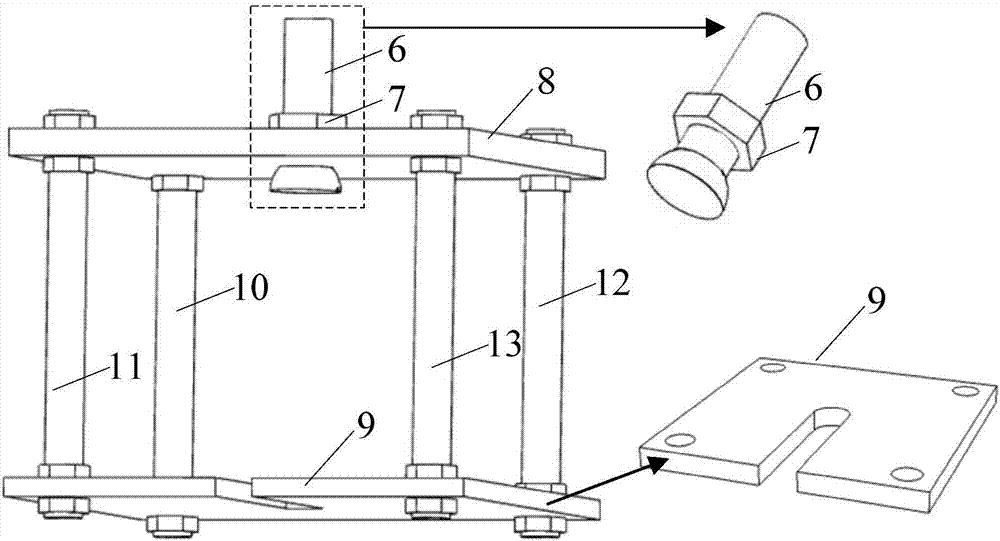

[0027] A steel bar and concrete pull-out test device that can eliminate the influence of high temperature is composed of an upper pull-out frame, a lower pull-out frame, anchors, slip measurement components and force measurement components, see Figure 1 to Figure 7 . The overall schematic diagram of the test device structure of the present invention is as figure 1 with 2 As shown, the upper pull-out frame 1 and the lower pull-out frame 2 are connected into one body through anchors 3 . pull-up frame such as image 3 Shown, it is made up of band ball joint screw rod 6, hex nut a7, platform plate a8, platform plate b9 and four connecting screw rods a10, 11, 12, 13. The screw end of the screw with ball hinge 6 is connected with the clamp on the hydraulic servo testing machine, the ball hinge end is positioned at the pre-opened hole in the center of the platform plate a8 through the hex nut a7, and the platform plate a8 and the platform plate b9 are connected by four The screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com