Shear device of full-computer glove machine

A glove machine, full computer technology, applied in textile and paper making, weft knitting, knitting and other directions, can solve the problems of clamping, unable to cut hard yarn, unable to weave, etc. Simple looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

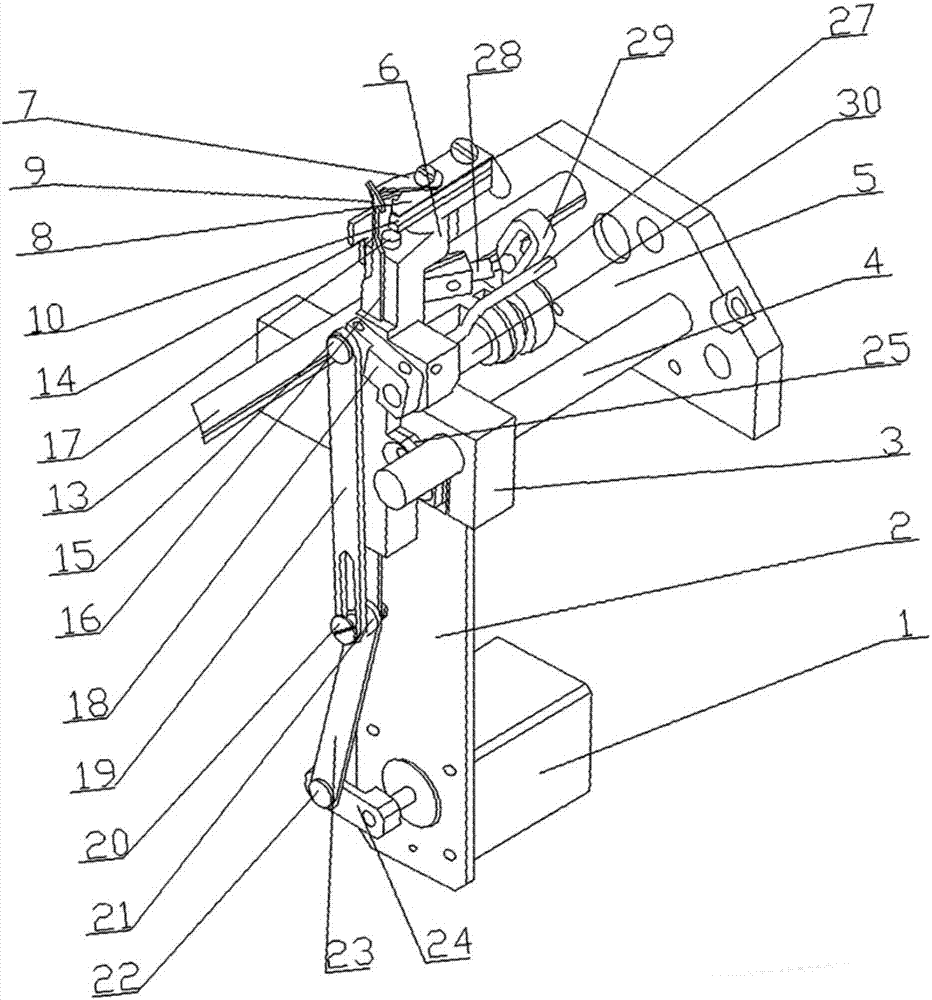

[0032] as attached figure 1 to attach Figure 7 As shown, a full computer glove machine scissors device includes: crimping piece 7, clamping piece 8, movable scissors 9, fixed scissors 10, scissors shaft 12, rotating arm 28, hook knife 16, blowing head 17, transmission pendulum Arm 18, stepper motor 1;

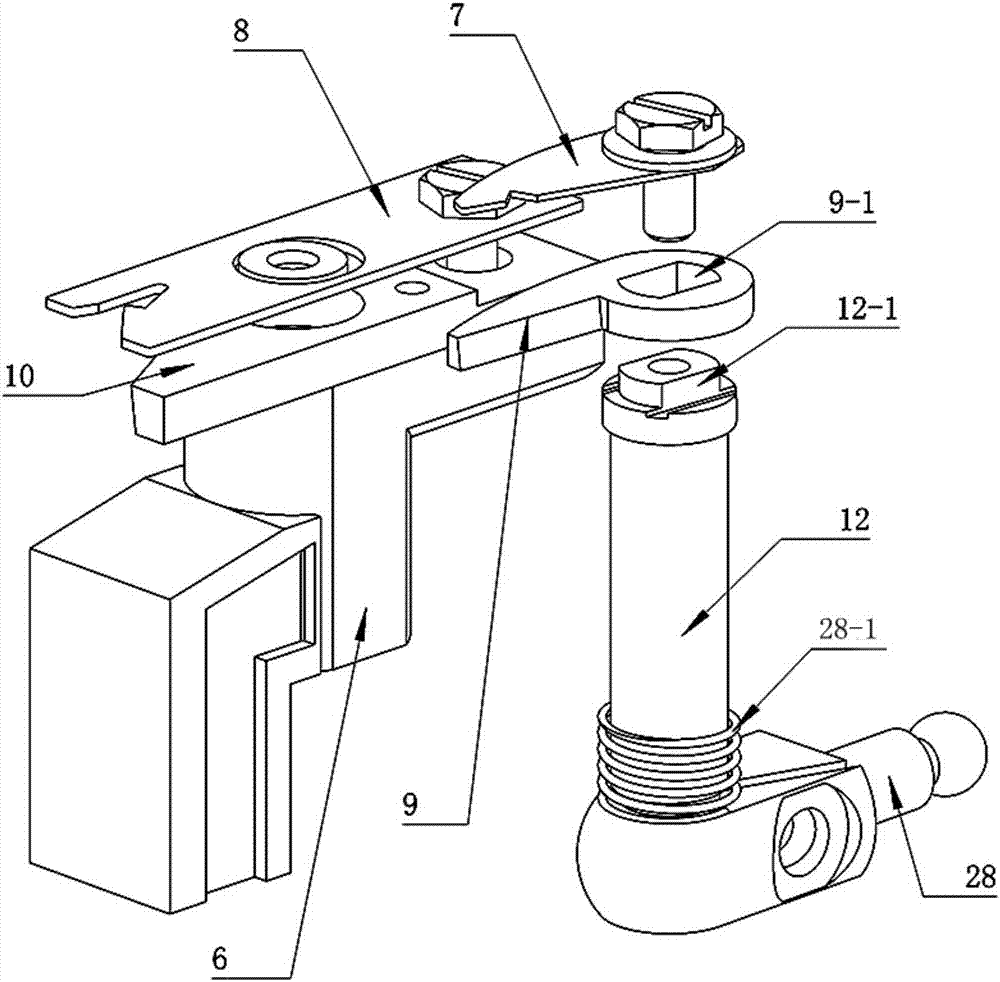

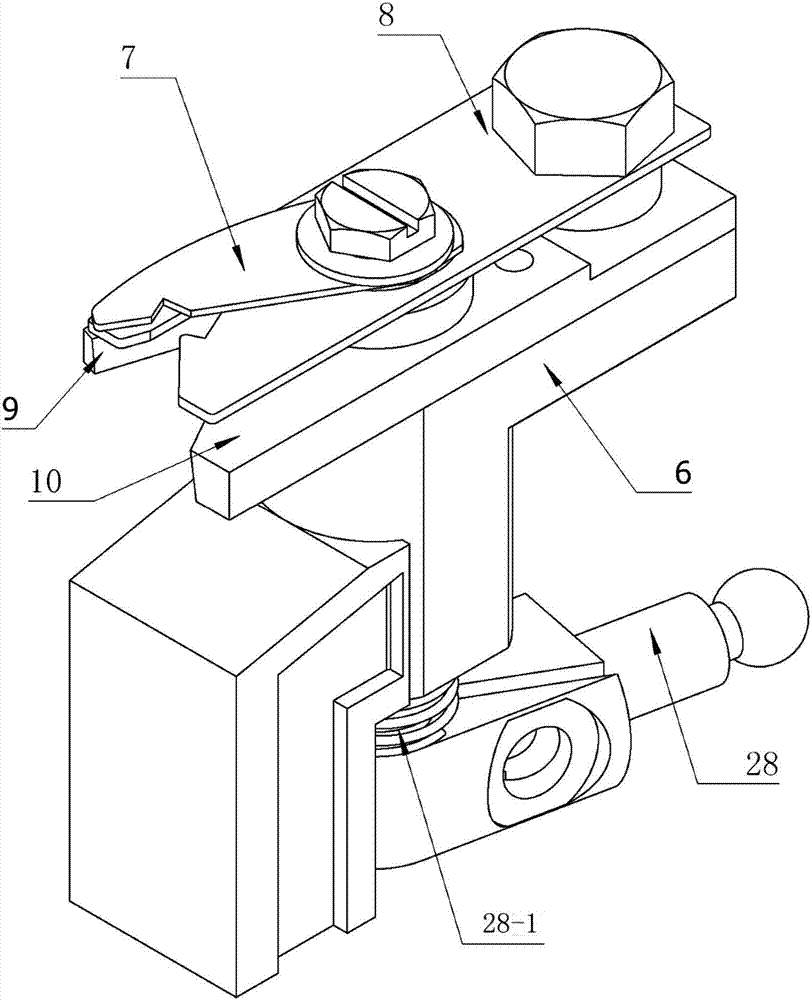

[0033] see Figure 2 to Figure 5 On the scissors shaft 12, the crimping piece 7, the clamping piece 8, the movable scissors 9, and the fixed scissors 10 are successively installed from top to bottom; The scissors shaft 12 top has the protrusion that is commonly called as " flat wire ", so-called " flat wire ", see figure 2 , which is defined as removing two pieces symmetrically at the top of the cylinder to form an outer contour consisting of two arcs and two straight lines. Movable scissors 9 has the through hole 9-1 of shape and size adaptation, and the through hole 9-1 of movable scissors 9 is enclosed within on the flat wire 12-1 protrusion of scissors shaft 12, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com