Apparatus for extending yellow lead production technology and realizing energy-saving preparation of tetrabasic lead sulfate

A four-basic lead sulfate and production process technology, applied in the direction of lead sulfate, etc., can solve the problems of long 4BS process time, insufficient 4BS purity, high production cost, etc., and achieve uniform product appearance, low energy consumption, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

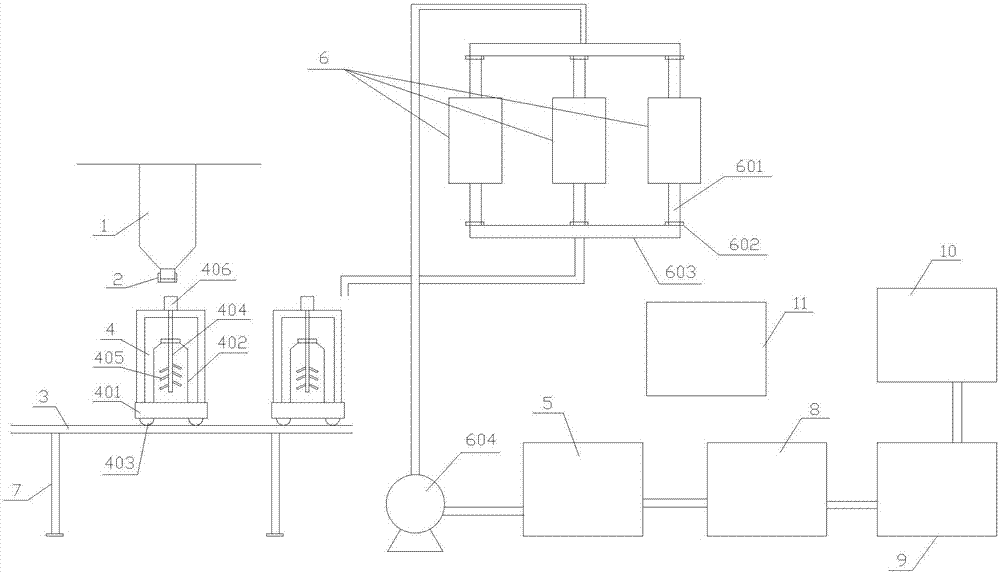

[0042] Such as Figure 1-2 As shown, a device for energy-saving preparation of tetrabasic lead sulfate by extending the production process of Huangdan, including: thermal insulation storage tank 1, automatic metering equipment 2, circular track 3, reaction tank 4, centrifugal device 5 and waste water collection tank 6 ;

[0043]The thermal insulation storage barrel 1 is set under the discharge port of the yellow dan calciner (not shown in the figure), and is used to store the yellow dan product coming out of the calcination furnace. The automatic metering device 2 (market mature equipment) is set in the thermal insulation storage barrel 1 At the feeding port, the circular track 3 is supported by the bracket 7 to form an elevated structure. A po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com