Composite material wing integrated fuel tank structure

An integral fuel tank and composite material technology, applied in the directions of wings, aircraft parts, transportation and packaging, can solve the problems of inability to use large and medium-sized UAV structures, no lightning protection function, weak bearing capacity, etc., and achieve structural weight. Lightweight, easy to service and maintain, high load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

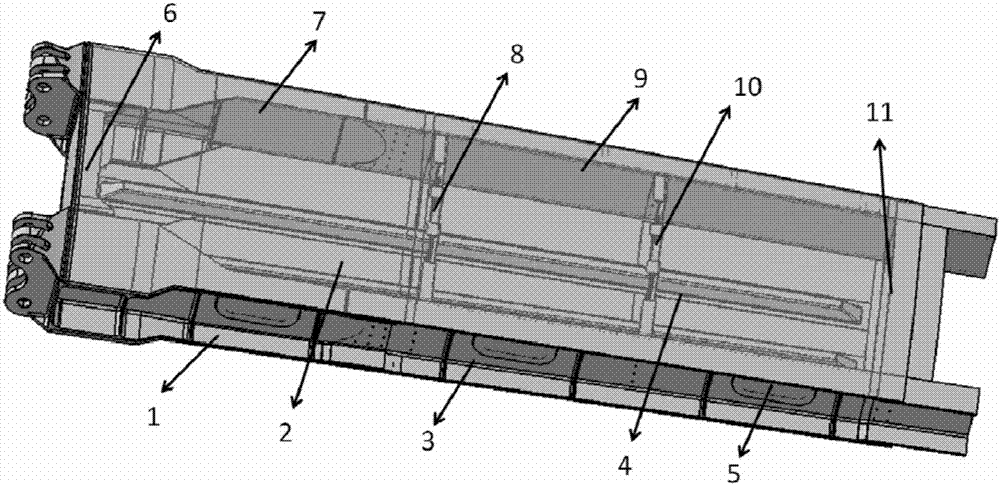

Embodiment

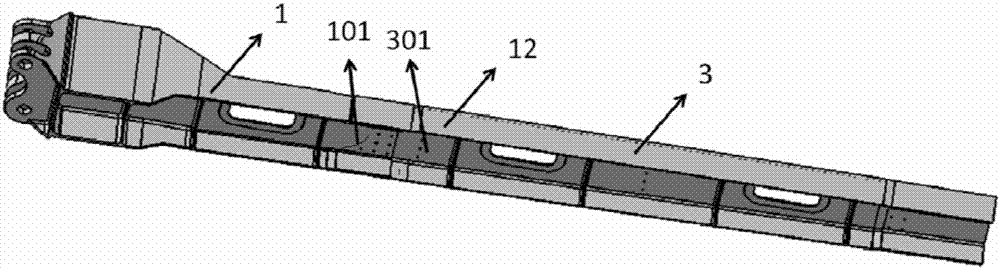

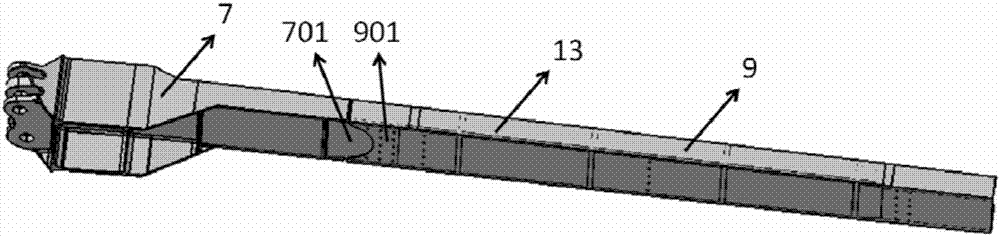

[0031] Preparation of composite material parts, including upper skin 2 and lower skin 4, and medium-temperature curing molding in an autoclave. When the upper skin 2 and the lower skin 4 are prepared, a metal mesh film is first pasted on the outer surface, and co-cured with the carbon fiber layup of the part to form, which greatly improves the conductivity of the composite skin and can have the function of lightning protection. The upper skin and the lower skin are made of carbon fiber composite material, as the main load-bearing structure, which can effectively reduce the structural weight.

[0032] After the parts are prepared, the surface treatment of the parts is carried out: the aluminum alloy parts are first anodized with chromic acid, and then coated with an anti-corrosion primer to improve the anti-corrosion ability of the aluminum alloy in the fuel medium; for the composite material parts, the inner surface is first sprayed with varnish, and then sprayed Antistatic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com