Automatic paging seal stamping mechanism

An automatic technology for stamping and stamping, applied in printing, stamping and other directions, can solve the problem that automatic stamping equipment cannot automatically stamp stamping stamps at the same time, and achieve stable, reliable, easy and accurate pick-and-place work, automatic stamping, and simple structure. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

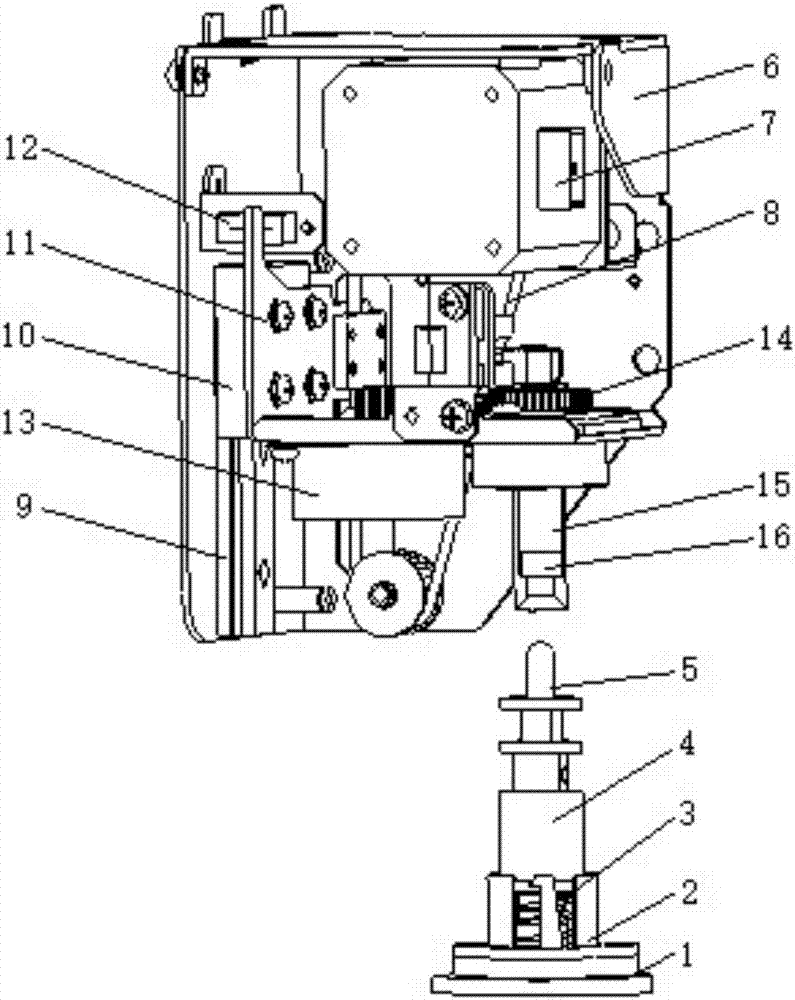

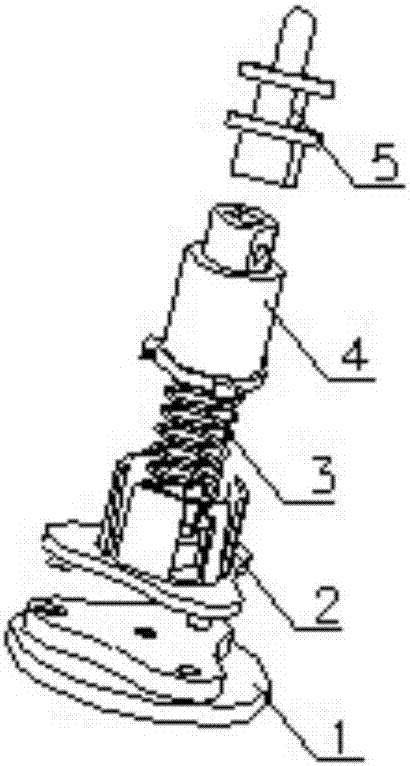

[0037] see Figure 1-7 , an automatic stamping mechanism for stamping with seals in the illustration is a preferred solution of the present invention, including two parts: a stamp taking module and a floating stamp, specifically including a stamp head 1, a first buckle 2, a telescopic spring 3, The second buckle 4, the head shaft 5, the chapter-taking main bracket 6, the lifting motor 7, the synchronous belt transmission assembly 8, the guide rail 9, the slider 10, the slider bracket 11, the lifting position sensor 12, the rotating motor 13, the gear reduction module 14. Take the chapter shaft sleeve 15, the magnet 16, the XY axis horizontal plane moving module 17 and other components.

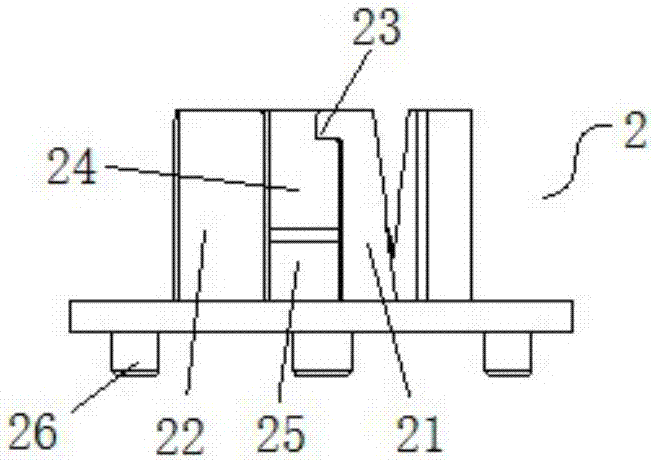

[0038] like Figure 2 to Figure 6 As shown, the floating seal is a seal used to affix a seam stamp on a document, wherein the stamp head 1 is rigidly connected to the first buckle 2, and the first buckle 2 and the second buckle 4 are elastically connected by a telescopic spring 3 , the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com