Automatic clamping clamp for aerial rudder grinding machining

A grinding and automatic clamping technology, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of low processing efficiency and accumulated processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

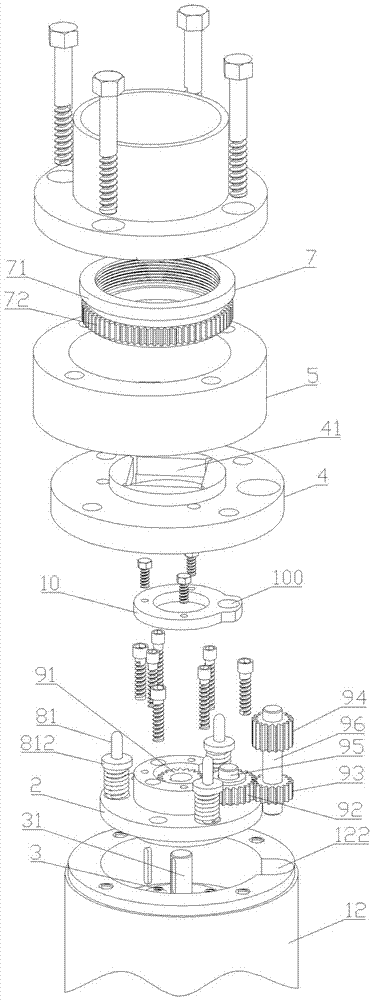

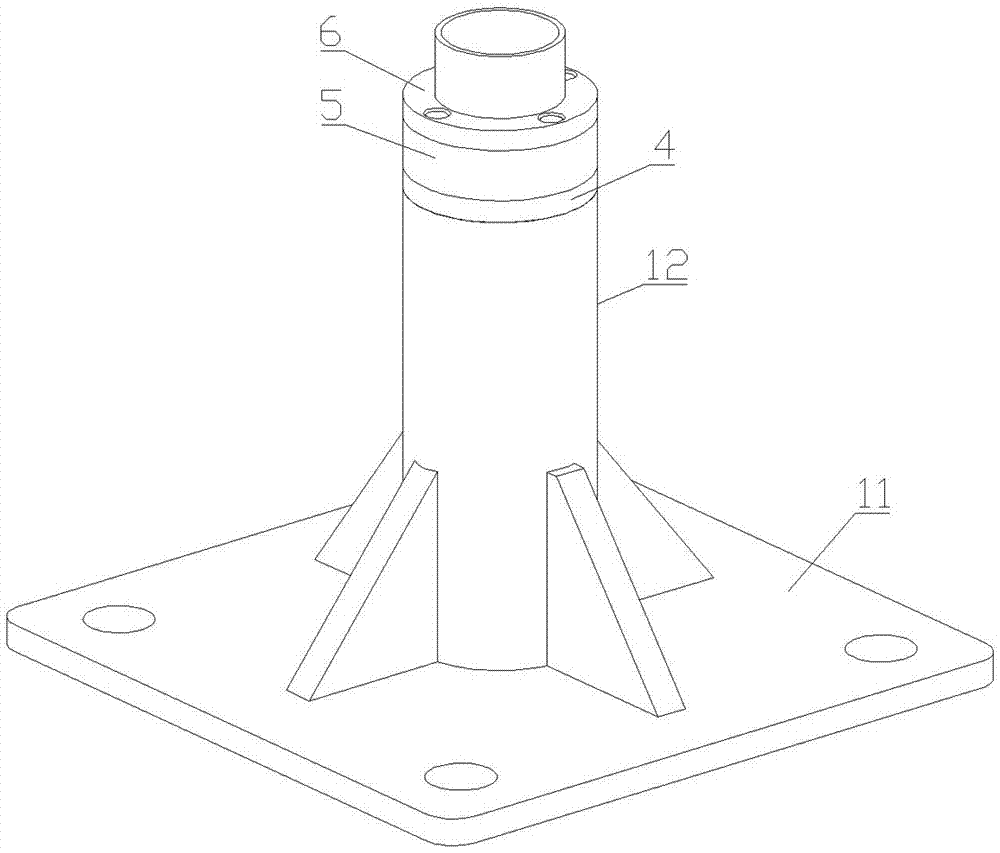

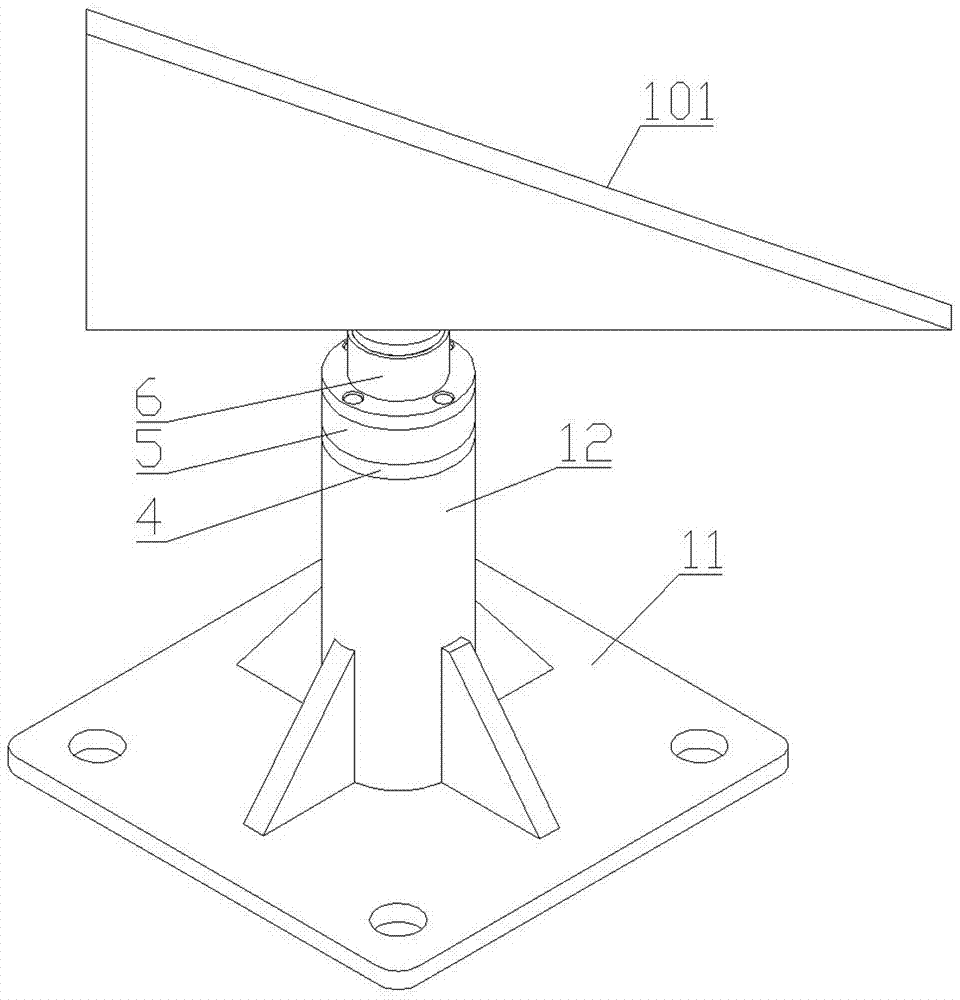

[0047] Such as Figure 1-13 As shown, the automatic clamping fixture for air rudder grinding includes a base, a step seat 2, a motor 3, an outer positioning cover 4, a sleeve 5, an inlet sleeve 6, a lock nut 7, an elastic push assembly, a transmission assembly and Position the cover 10 inside.

[0048] The base includes a bottom plate 11 and a motor seat 12 . The motor base 12 is in the shape of a sleeve and is vertically fixed on the upper end of the base plate 11. Its upper end is provided with a gear shaft hole B122, and a stepped hole 121 is provided in it. The end of the stepped hole 121 near the base plate 11 is a small-diameter section 1211, which is far away from the base plate. One end of 11 is a large-diameter section 1212, and a stepped surface 1213 is provided between the large-diameter section 1212 and the small-diameter section 1211. The large-diameter section 1212 of the stepped hole 121 forms an opening 1214 for the motor 3 to be installed at the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com