Automatic Imaging Magnetic Particle Flaw Detector and Method for Railway Wheel Axle

A technology of magnetic particle flaw detection and wheel shaft, which is applied in the direction of material magnetic variables, etc., can solve the problems of high accuracy of flaw detection results, low false detection rate, low labor intensity, etc., and achieve the goal of increasing flaw detection speed, improving accuracy, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

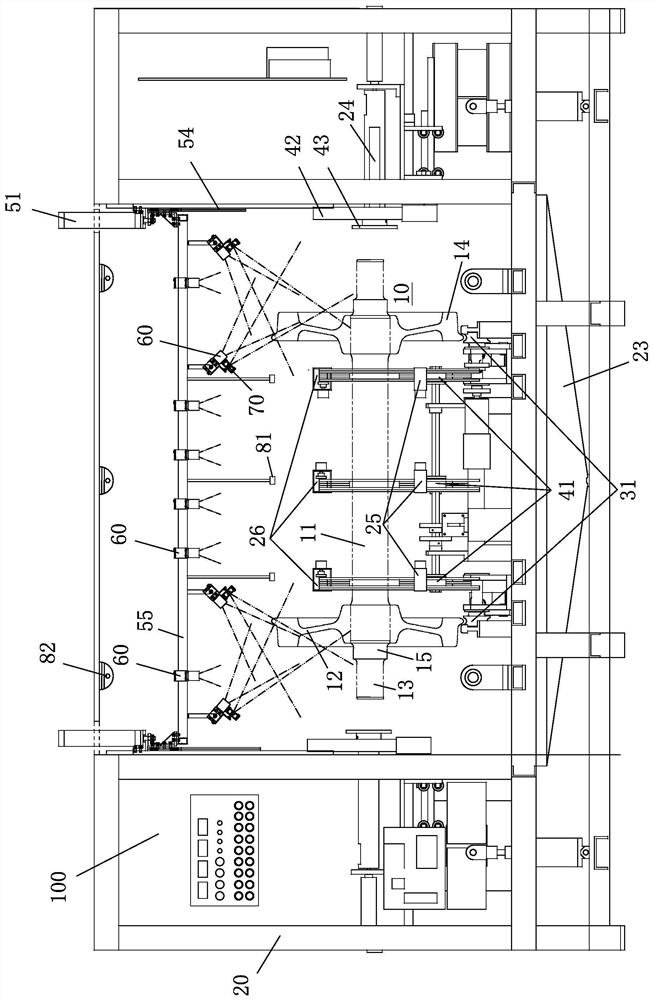

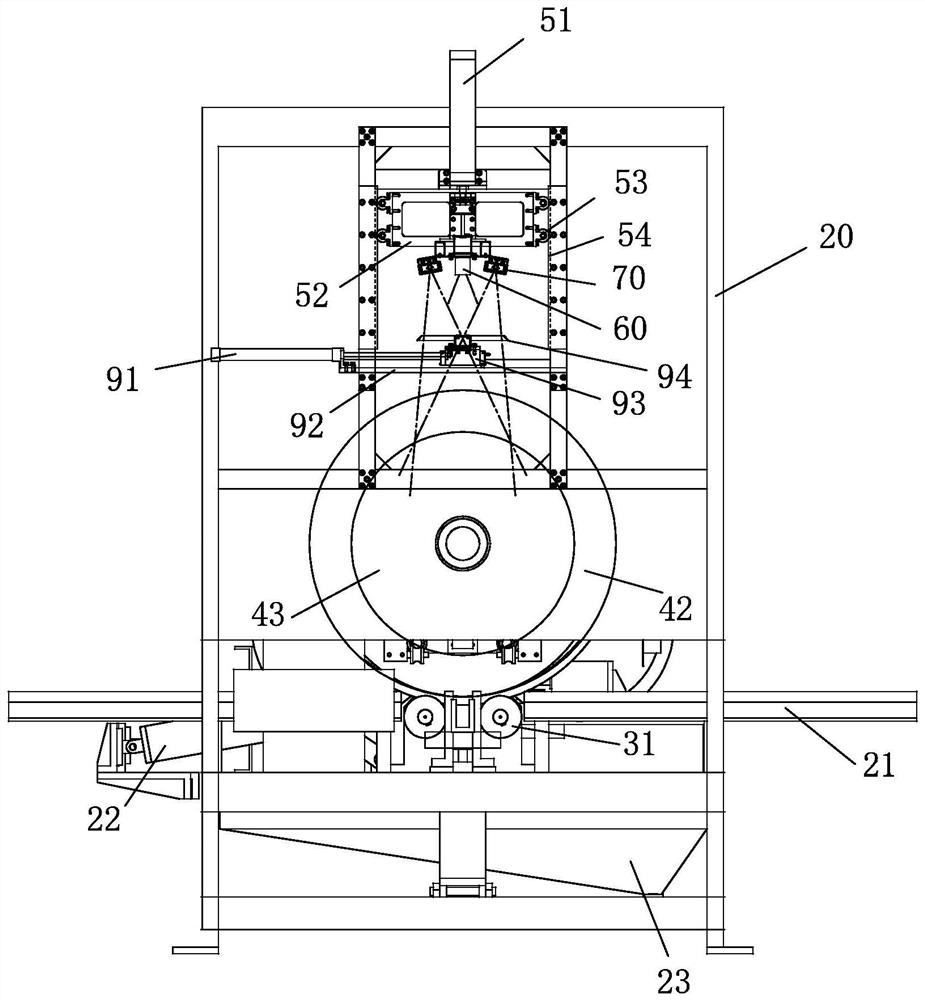

[0035] The automatic imaging magnetic particle flaw detection machine of the railway wheel axle of the present invention is located on the wheel set inspection and maintenance assembly line, and is connected with the inner track of the production site. Such as figure 1 and figure 2 As shown, the railway axle automatic imaging magnetic particle flaw detector of the present invention includes a frame 20, a workpiece feeding mechanism 21 (track passing type) responsible for sending the wheel axle 10, a workpiece sending mechanism 22 (rail passing type) responsible for sending the wheel axle 10, a support The rotating mechanism that holds the axle 10 and drives the axle 10 and the wheels 14 to rotate, the magnetic suspension spraying system 23 that is responsible for the spraying and recovery of the magnetic suspension, the axle circumferential magnetization mechanism that magnetizes the axle 10 in the circumferential direction, and the axle 10 that performs longitudinal magnetiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com