Small thrust measuring device

A measuring device, small thrust technology, applied in the direction of measuring device, force/torque/work measuring instrument, force/torque/work measuring instrument calibration/testing, etc., can solve the problem that the mechanical lever device cannot be statically calibrated with dynamic force measuring components , The sliding or rolling performance and quality of the movable device are very different, the maintenance and replacement of the movable device, lubrication, dust prevention and other problems are complicated, so as to achieve the effect of shortening the test preparation time, strong maintainability and strong replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

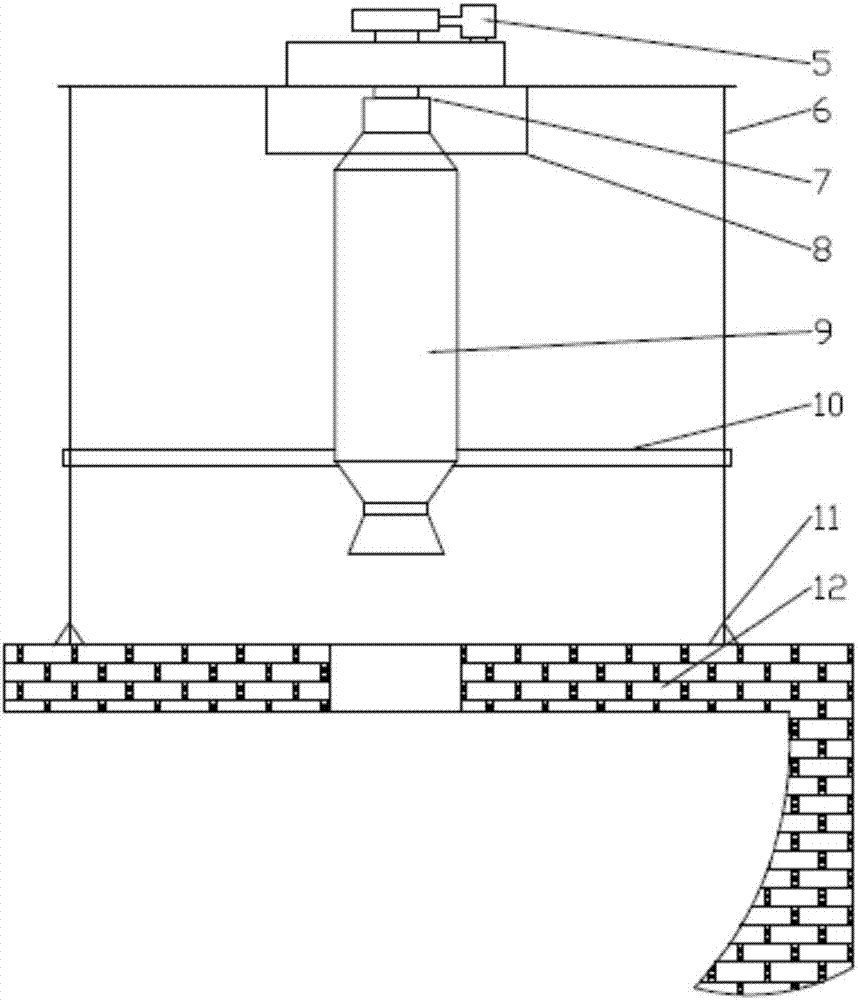

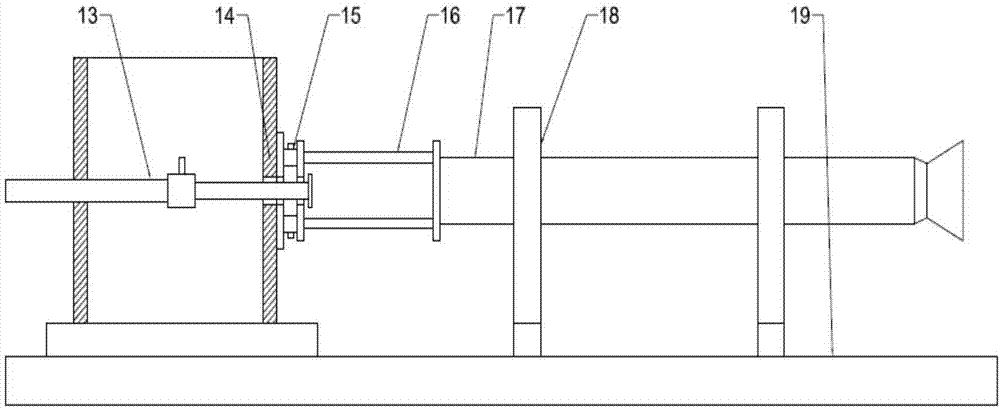

[0055] The following uses a pulse detonation engine with an aspect ratio of about 1000mm / 60mm as an example to illustrate the use of this small thrust measuring device, and it is necessary to flexibly select relevant parts for different types of engines to apply the device of the present invention.

[0056] The application of the device of the present invention is divided into two steps, one is to assemble the thrust measurement system and the engine; the other is to debug the thrust measurement system.

[0057] The assembly steps are, in sequence, the static frame 14 , the in-situ calibration device 13 , the force measuring assembly 15 , the moving frame 16 , the suspension component 18 and the engine 19 .

[0058] The main content of debugging the thrust measuring system is to adjust the coaxiality of the engine 18 and the force measuring assembly 19 . Finally, the assembly schematic is shown in image 3 .

[0059] The static frame 14 is fastened on the working platform 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com