Sensor for detecting the temperature and vibration position of fully distributed optical fiber

A fully distributed, vibration position technology, applied in the field of sensors, can solve problems such as high cost, and achieve the effects of low overall cost, high measurement accuracy, and convenient and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

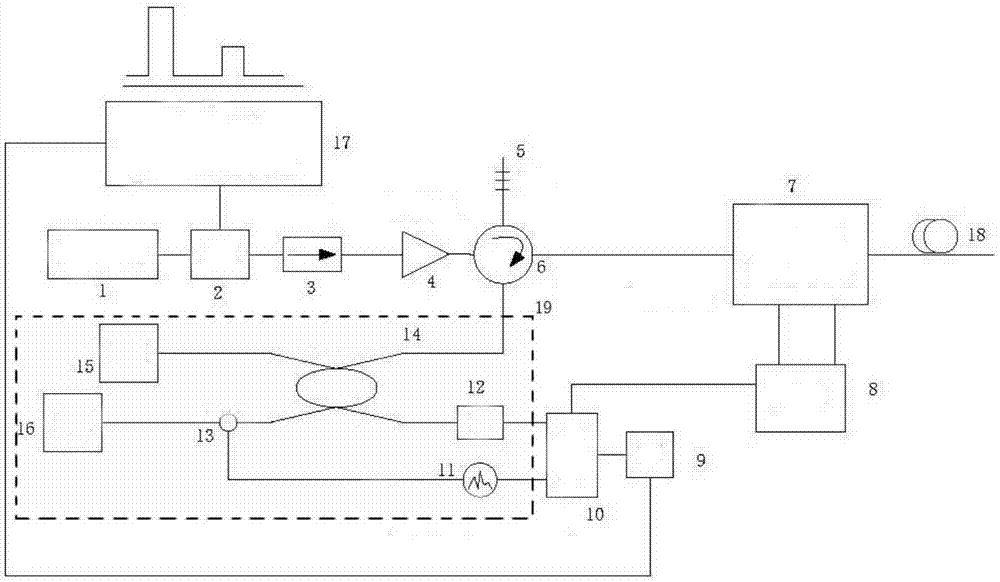

[0037] Such as figure 1 As shown, it is a schematic diagram of the sensor used to detect the temperature and vibration position of the fully distributed optical fiber of the present invention in use. The sensor described in this embodiment includes: laser 1, acousto-optic modulator 2, isolator 3, erbium-doped fiber amplifier 4, fiber Bragg grating 5, circulator 6, Raman wavelength division multiplexer 7, avalanche diode 8. Data collector 10, pulse generator 17 and Rayleigh scattered light processing unit 19, Rayleigh scattered light processing unit 19 includes: phase carrier signal modulator 11, photodetector 12, piezoelectric ceramic sheet 13, coupler 14 , Faraday mirror 15, Faraday mirror 16.

[0038]The input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com