Tail gas catalyst of flameproof diesel engine for mining

A mining explosion-proof, diesel engine technology, applied in the direction of machines/engines, exhaust treatment, exhaust devices, etc., can solve the problems of underground workers' injuries, reduce soot content, exhaust pollution, etc., and achieve increased stability and durability , reduce clogging, good catalytic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings.

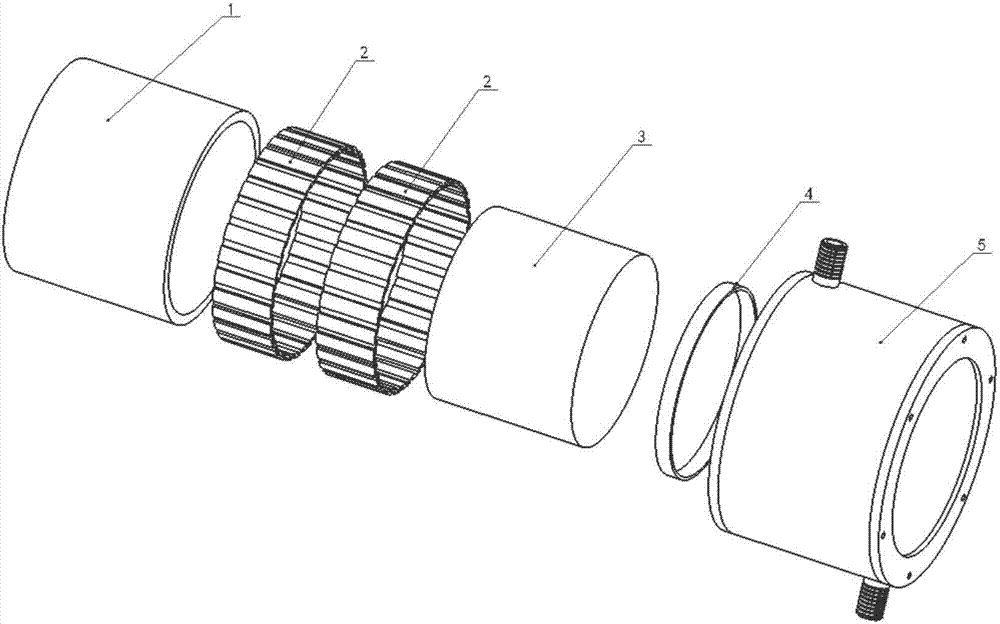

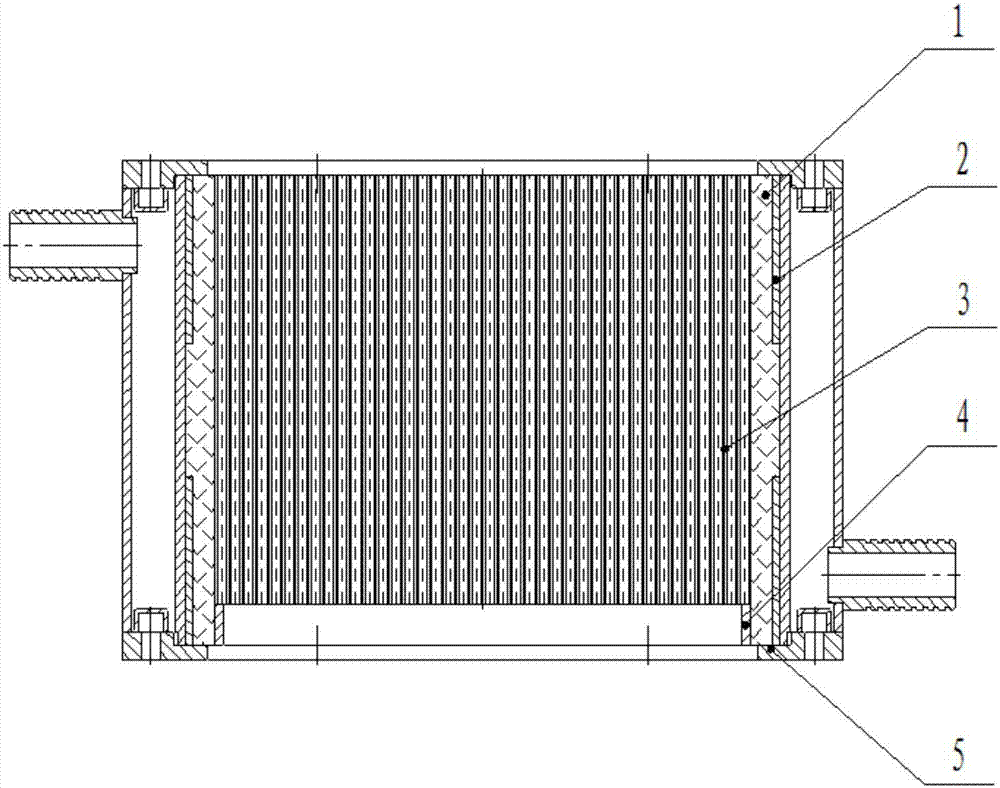

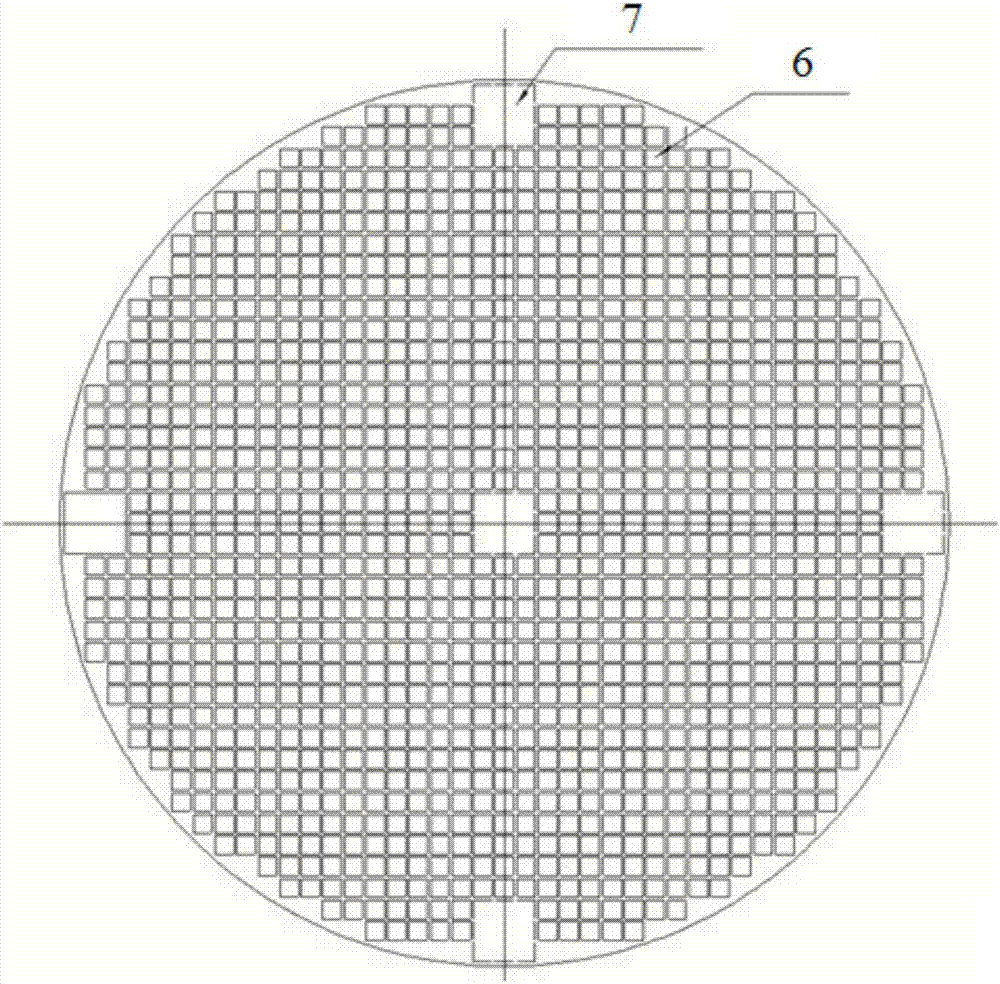

[0025] Such as figure 1 , 2 As shown, the mine explosion-proof diesel engine tail gas catalytic converter includes a water jacket housing 5, the water jacket housing 5 is a drum body, and the barrel wall is a double-layer structure, including an inner wall and an outer wall, and a water jacket is arranged between the inner wall and the outer wall layer, the outer wall is provided with water inlet and outlet, and the surface temperature of the device is guaranteed not to exceed 150°C by water cooling; the inner wall of the water jacket shell 5 is provided with a catalytic unit 3, such as image 3 As shown, the catalytic unit 3 is provided with a plurality of straight-through small air passages 6 and 5 bypass large passages 7 along the axial direction, wherein one bypass large passage 7 is set at the center of the catalytic unit 3, and 4 are evenly distributed in the catalytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com