A high-durability cement concrete pavement expansion joint structure and its construction method

A cement concrete, durability technology, applied in the direction of roads, roads, pavement details, etc., to achieve the effect of improving the overall quality, enhancing the durability, and reducing the cost of pavement maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

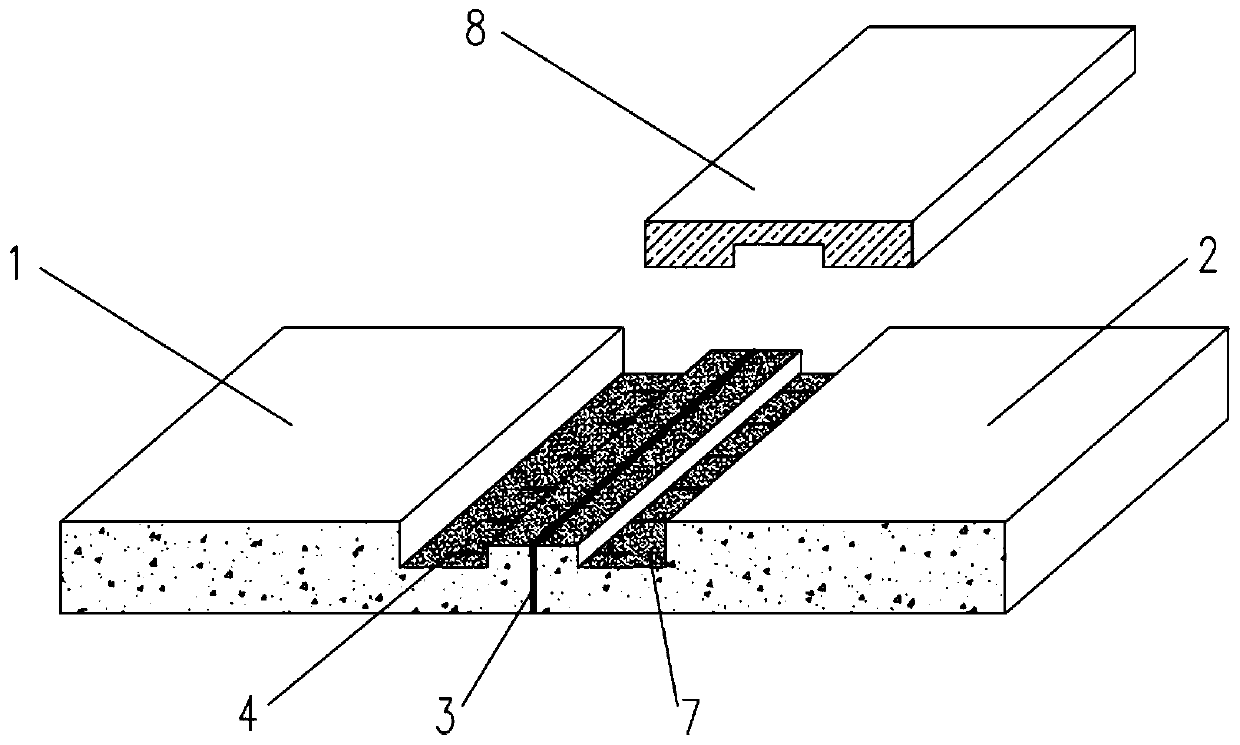

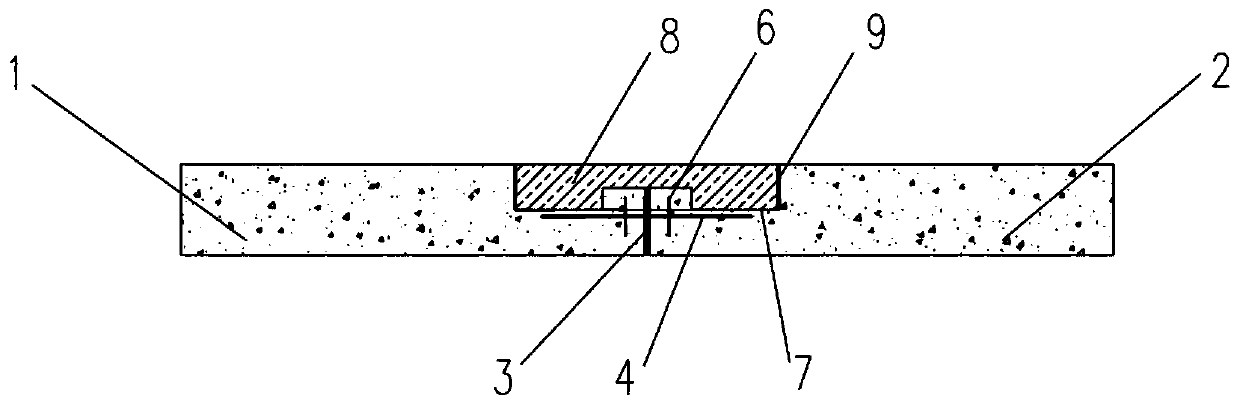

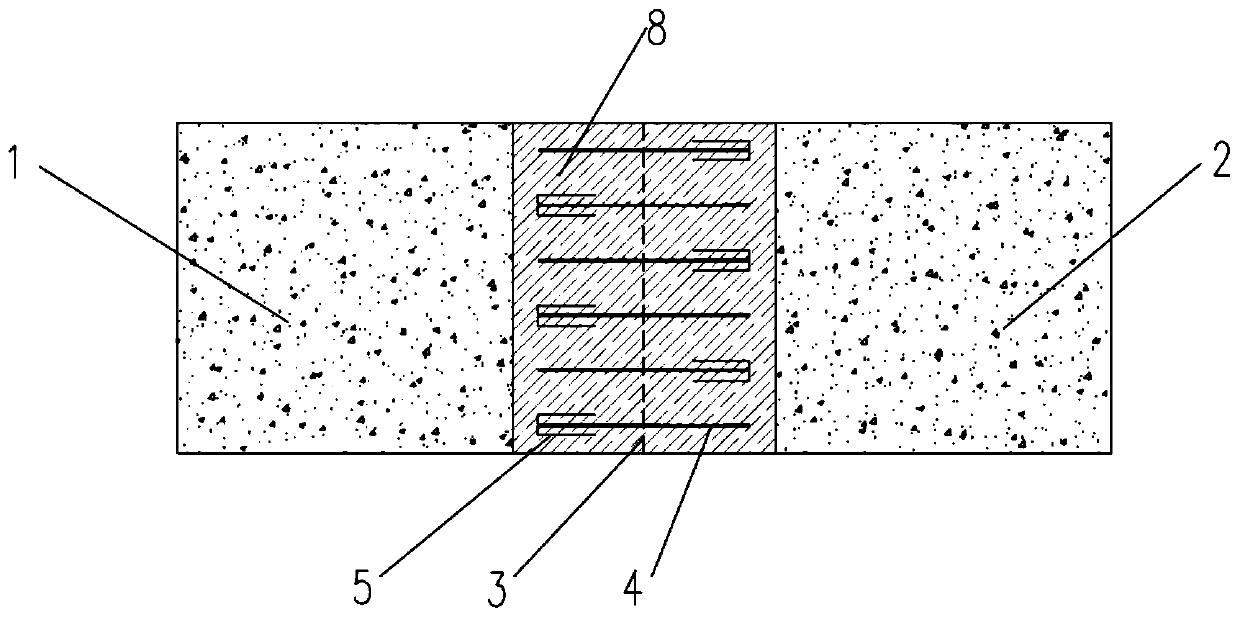

[0028] see Figure 1-3 , a high-durability cement concrete pavement expansion joint structure, including two concrete slabs (1, 2), an expansion joint 3 is arranged between the concrete slabs, and two concrete slabs near the expansion joint 3 are provided with concave The concave structure of the groove and the semi-convex platform, the two concave structures together form the convex structure, and the two semi-convex platforms together form the convex structure of the convex structure;

[0029] In the concrete slab at the lower part of the convex structure, dowel bars 4 parallel to the length direction of the concrete slab are provided, and vertical steel bars 6 are arranged in the semi-bosses on both sides of the expansion joints. One end is provided with a sleeve 5, and the direction of the sleeves of adjacent dowel bars is opposite;

[0030] The expansion joint structure of the high-durability cement concrete pavement also includes a cover plate 8 covering the convex stru...

Embodiment 2

[0035] The embodiment of the present invention provides a method for setting expansion joint structure of high-durability cement concrete pavement, including two adjacent concrete slabs 1 and 2, the concrete slab is 5m long, 4m wide, and 28cm thick. The sides of the two concrete slabs close to the expansion joints are made into a concave form as shown in the figure, and the two slabs are combined to form a convex expansion joint structure as shown in the figure.

[0036] The total width of the convex part of the convex structure is 0.5m, the thickness of the concrete layer is 17cm, the width of the middle expansion joint 3 is 2.5cm, and the expansion joint plate is filled in the joint; the width of the lower part of the convex structure is 0.5m, and the thickness of the concrete layer is 14cm.

[0037] When the concrete slab is poured, the dowel 4 coated with asphalt on one side and attached to the 10cm casing 5 is fixed with a bracket. The dowel is 50cm long and 28mm in diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com