Three-stage orbit injection space launch vehicle

A carrier and track technology, applied in the direction of aerospace vehicle propulsion system devices, etc., can solve the problems of high technical difficulty, large flight Mach number Ma span, and large take-off mass of the carrier, so as to improve engine thrust and reduce design difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

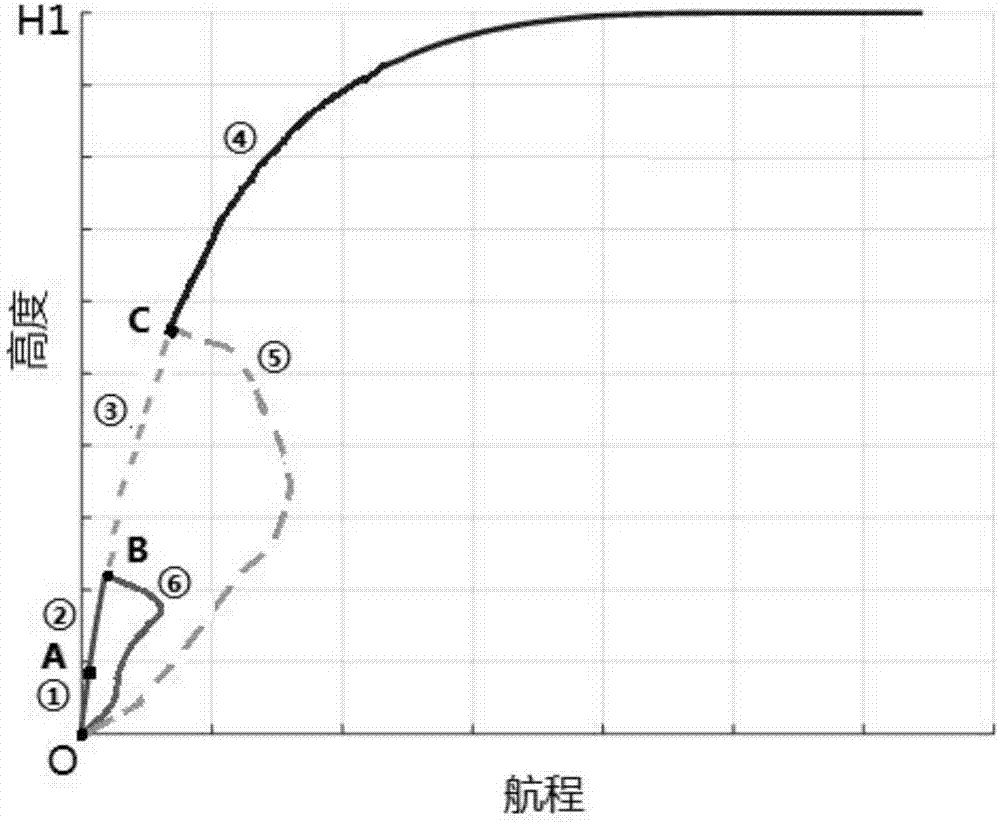

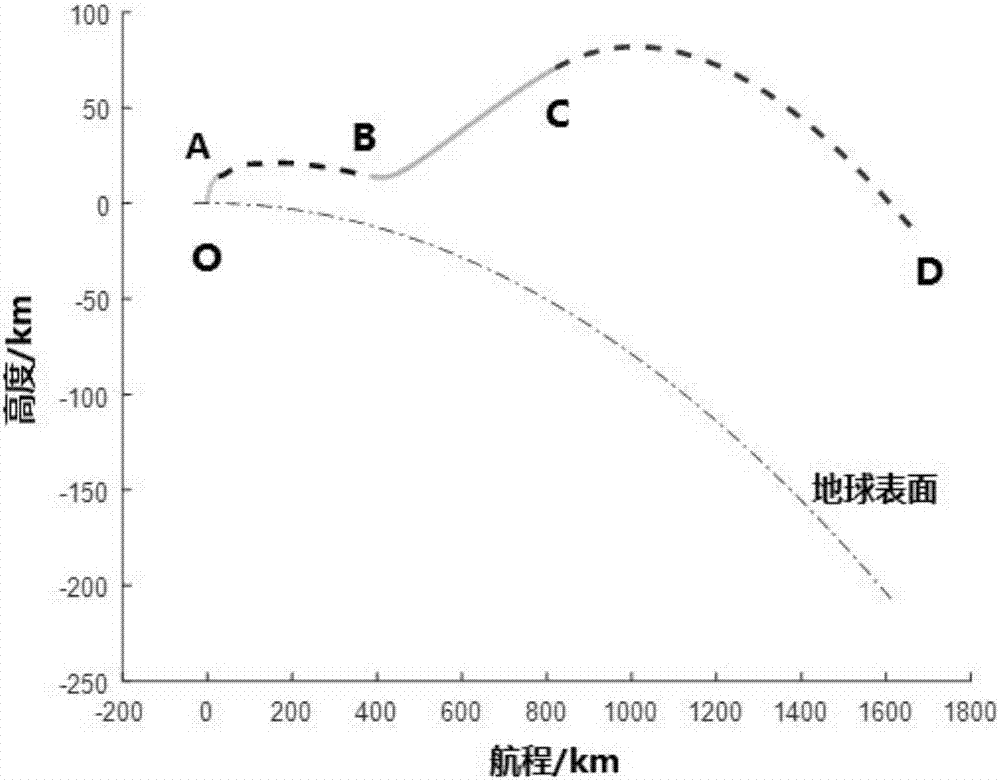

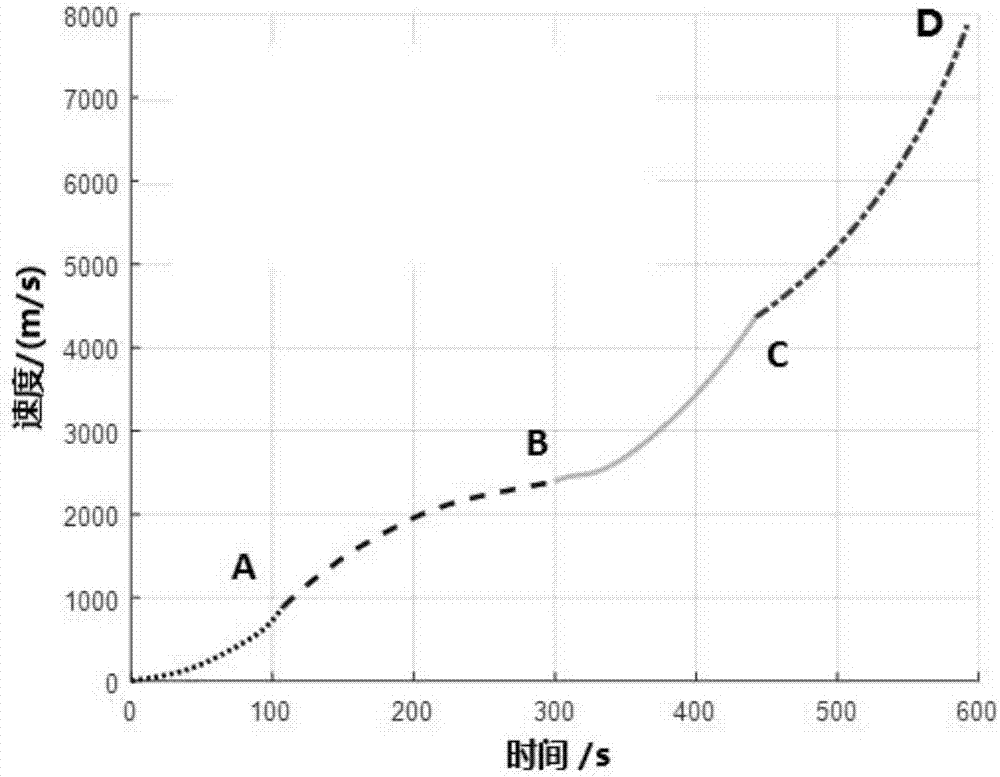

[0053] Taking 200km circular orbit and 500kg payload as an example, the overall parameters and trajectory of the three-stage orbital space vehicle in the present invention have been calculated, as figure 2 and image 3 .

[0054] figure 2 and image 3 In the OA section, the engines of the first-stage RBCC-powered aircraft and the second-stage RBCC-powered aircraft work together; in the AB section, the engines of the first-stage RBCC-powered aircraft work independently; in the BC section, the engines of the second-stage RBCC-powered aircraft work; CD The segment works for the engines of the third-stage rocket-powered vehicle. When point A is Ma=2.5 Mach, the engine shutdown point of the second-stage RBCC powered aircraft, point B is the separation point of the first-stage RBCC-powered aircraft and the second RBCC-powered aircraft and the third-stage rocket-powered aircraft, and point C is the first-stage RBCC-powered aircraft. The point where the second-stage RBCC-powered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com