Worm type robot

A technology of robots and worms, which is applied in the fields of motor vehicles, transportation and packaging, can solve the problems of inability to adjust the stroke, complex structure, and inability to adapt, and achieve the effects of simple mechanism, reliable movement and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

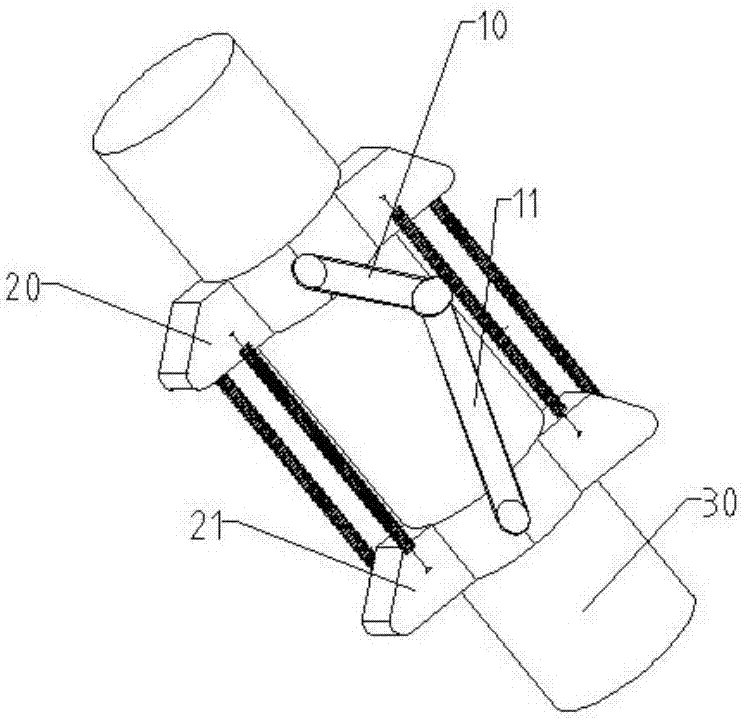

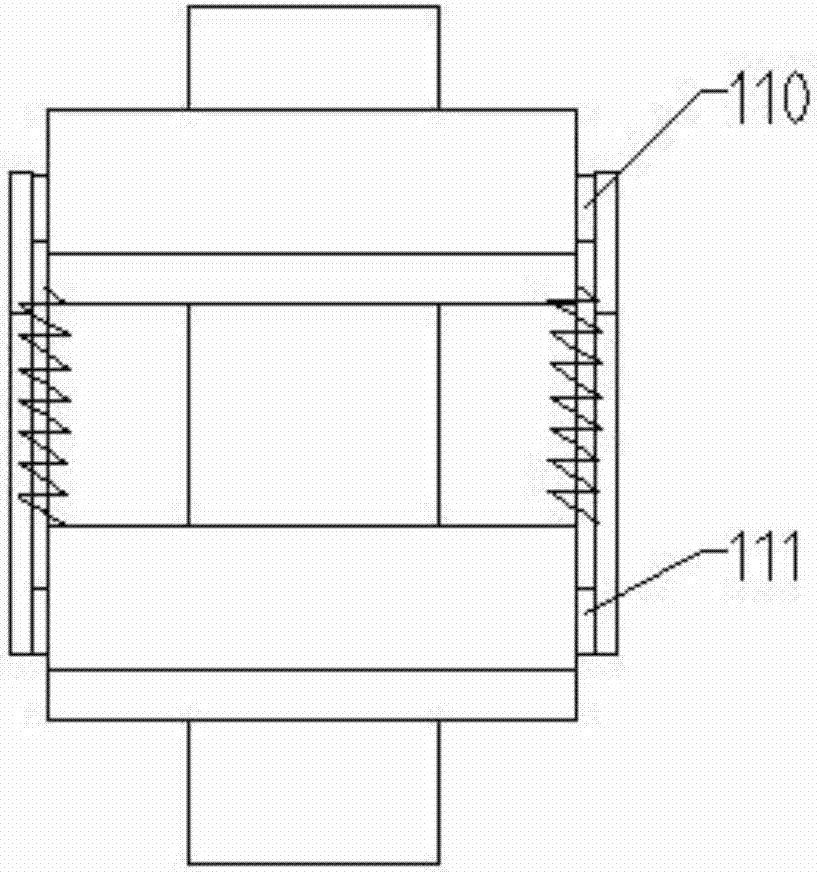

[0034] Such as Figure 1-11 As shown, a worm robot, which includes,

[0035] The self-locking sleeve pair includes an upper self-locking sleeve 20 and a lower self-locking sleeve 21, and the upper self-locking sleeve 20 and the lower self-locking sleeve 21 are all provided with through holes for being sleeved on the column 30 and crawling. Both ends of the sleeve 20 and the lower self-locking sleeve 21 are provided with a trapezoidal arc structure;

[0036] Self-locking ball 213, the cavity formed by the trapezoidal arc structure and the upper self-locking sleeve 20 and the lower self-locking sleeve 21 is provided with a self-locking ball 213, and the diameter of the self-locking ball 213 is larger than the above-mentioned trapezoidal arc structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com