Adjustable automatic fastening splicing and inserting type clamp

A technology of splicing and fastening, which is applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of fixture design and production cost increase, single fixture design, narrow application range, etc., and achieve a wide range of use and firmness Good, versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

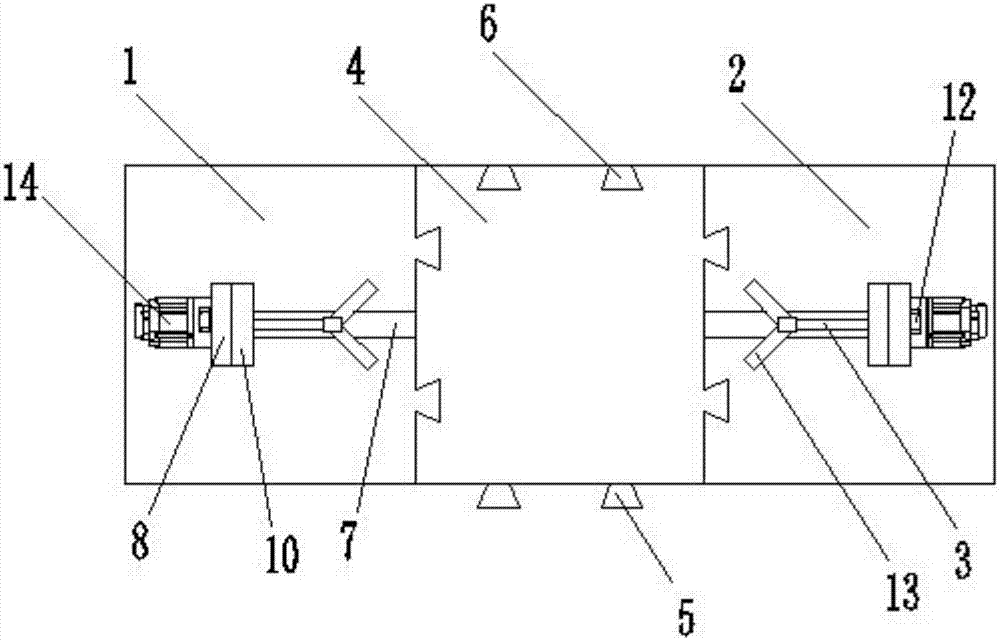

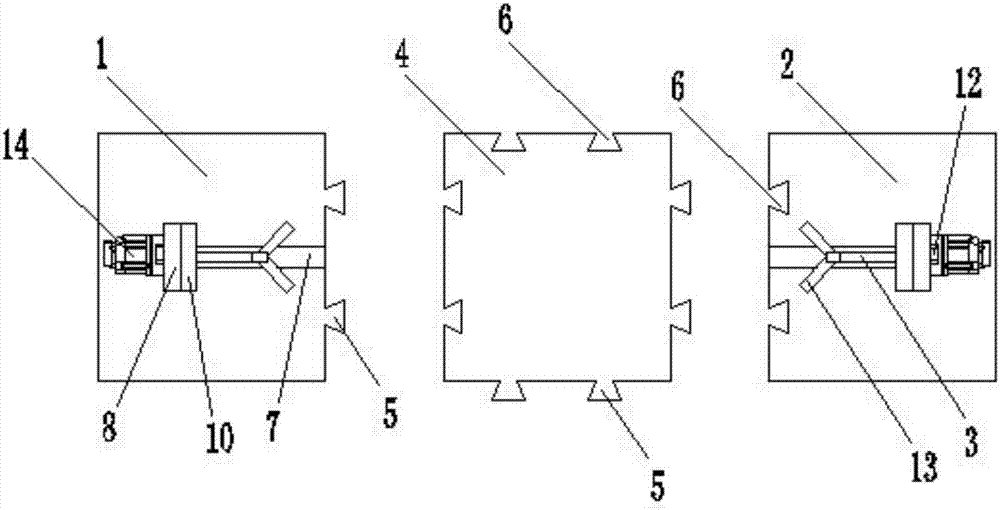

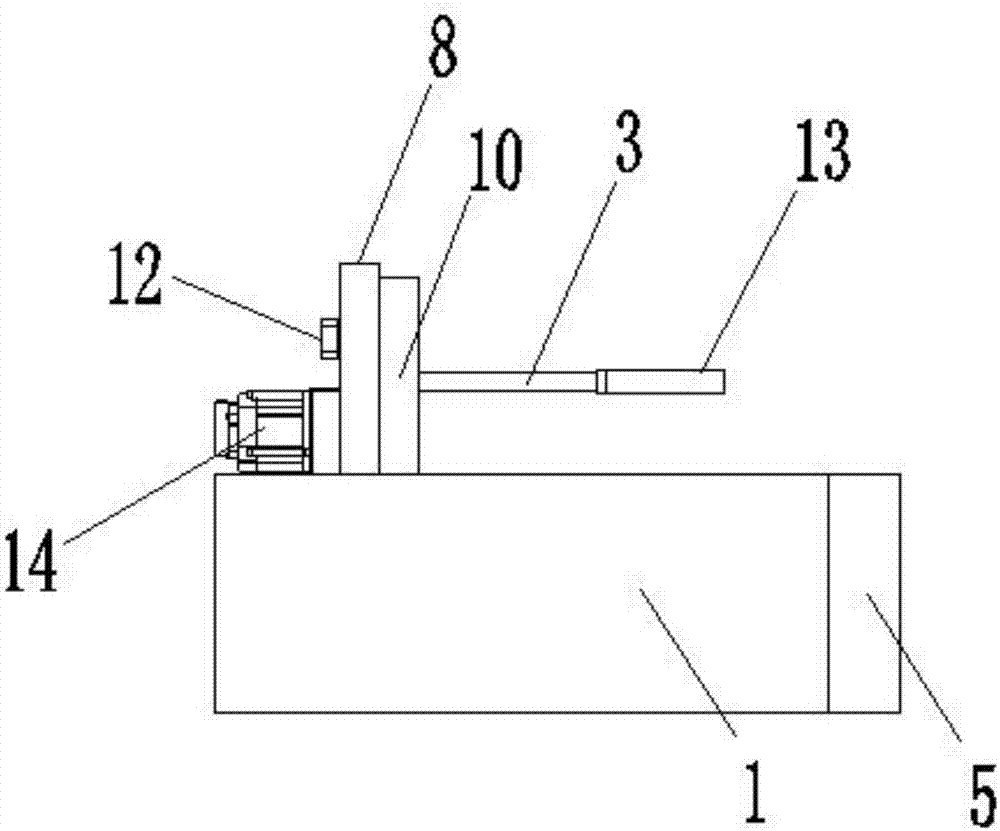

[0018] attached Figure 1-4 It is an adjustable automatic fastening splicing fixture according to the present invention, which includes a left inserting block 1, a right inserting block 2, a fastening rod 3 and a splicing block 4; the left inserting block 1, the right inserting block 2 and The splicing blocks 4 are rectangular hexahedrons with the same shape; the right side of the left plug 1 is provided with a dovetail bump 5; the left side of the right plug 2 is provided with a dovetail groove 6; The dovetail-shaped projection 5 and the dovetail-shaped groove 6 are matched and inserted; the upper surface of the left insert block 1 and the upper surface of the right insert block 2 are provided with a chute 7; There is a positioning slider 8; the positioning slider 8 is provided with a positioning through hole 9; the positioning slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com