Outlet strip steel surface roughness control method suitable for hot continuous rolling unit

A technology of surface roughness and hot tandem rolling, applied in rolling mill control device, metal rolling, profile control, etc., can solve problems such as troublesome operation, neglect of control effect, limited variation range of export strip restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

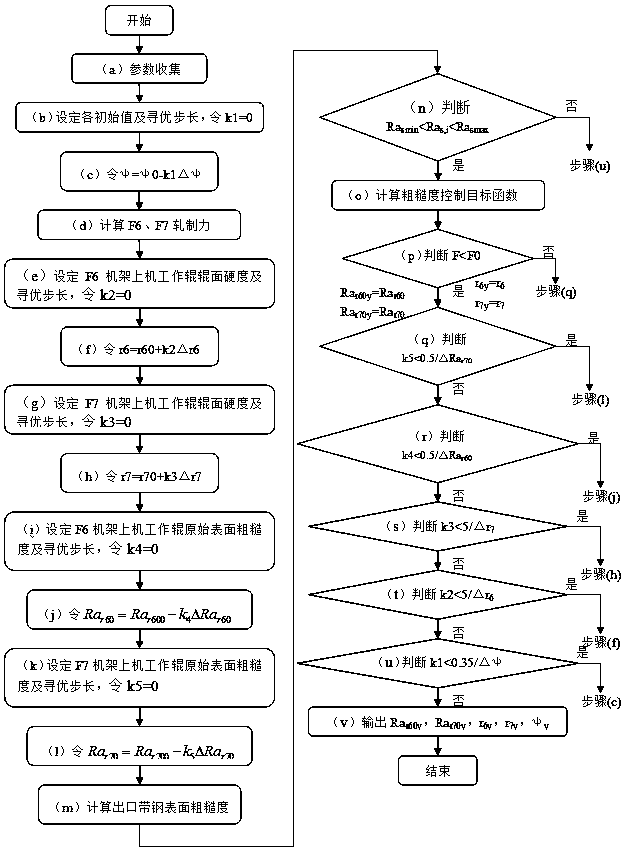

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0043] In order to further illustrate the application process of the technology of the present invention, taking a hot continuous rolling mill as an example, a specific implementation process of a method for controlling the surface roughness of the strip steel at the outlet of the hot continuous rolling mill is introduced in detail.

[0044] (a) parameter collection;

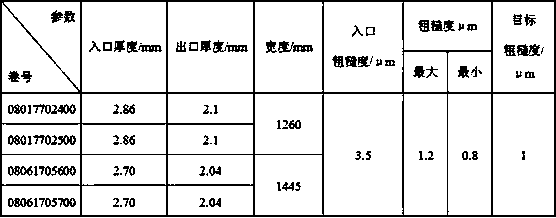

[0045] (a1) Collect the characteristic parameters of 4 coils of strip steel, mainly including: F6 frame strip steel entrance thickness , F7 rack strip outlet thickness , strip width , F6 rack entrance strip steel surface roughness , the maximum value of the surface roughness of the export strip allowed by the user and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com