Wedge-shaped connecting hardware tool

A technology of connecting fittings and wedges, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problem of inconvenient electric power repair, and achieve the effect of high applicability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

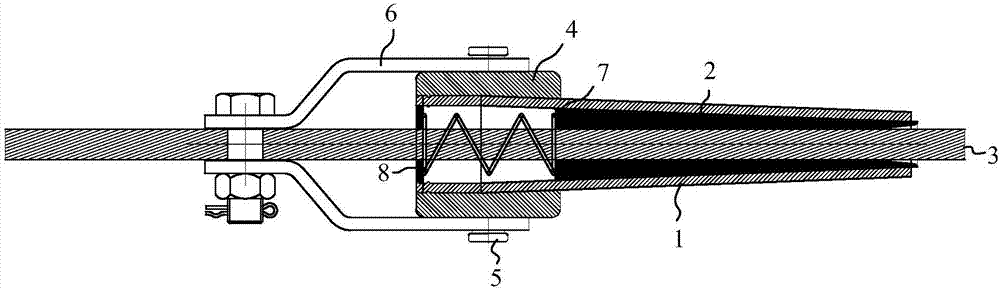

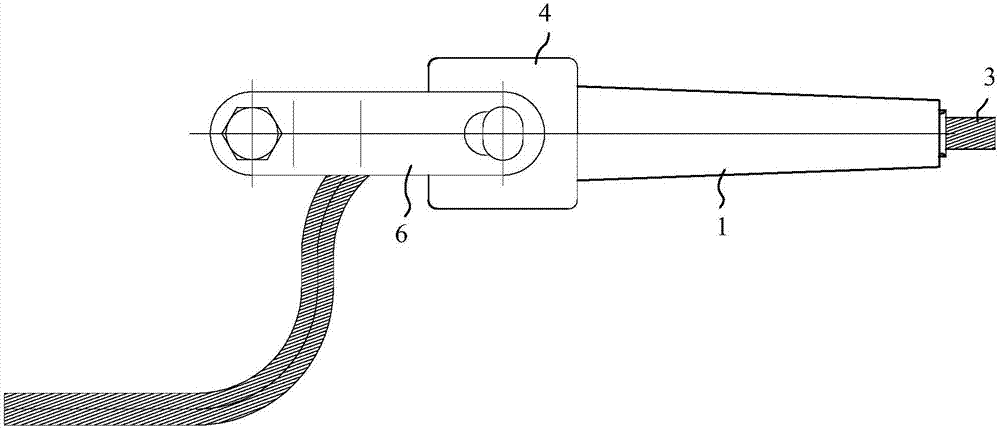

[0026] see Figure 1-Figure 5 , the present invention provides a wedge-shaped splicing fitting, comprising a metal sleeve 1, preferably an aluminum alloy sleeve with uniform wall thickness, the metal sleeve 1 has a straight pipe section and a tapered pipe section, and the inside of the tapered pipe section is arranged There is a wedge block 2 which has an outer tapered surface matched with the inner pipe wall of the tapered pipe section and an inner hole 21 through which the cable can pass and clamp the cable 3 . When the present invention is used, the cable 3 is passed through the inner hole 21 of the wedge block 2, the wedge block 2 is located inside the tapered pipe section, and the outer tapered surface of the wedge block 2 cooperates with the inner pipe wall of the tapered pipe section to realize the clamping of the cable 3 Tight, the metal casing 1 is provided with a puller 4 and a hanging plate 6 connected to the puller 4 through a pin 5 on the outside of the straight p...

Embodiment 2

[0032] see Figure 6-Figure 7 In this embodiment, on the basis of Embodiment 1, a drainage clamp 9 is added, that is, the metal sleeve 2 is provided with a drainage clamp 9 in the straight pipe section, and the cable 3 is reversed through this structure.

Embodiment 3

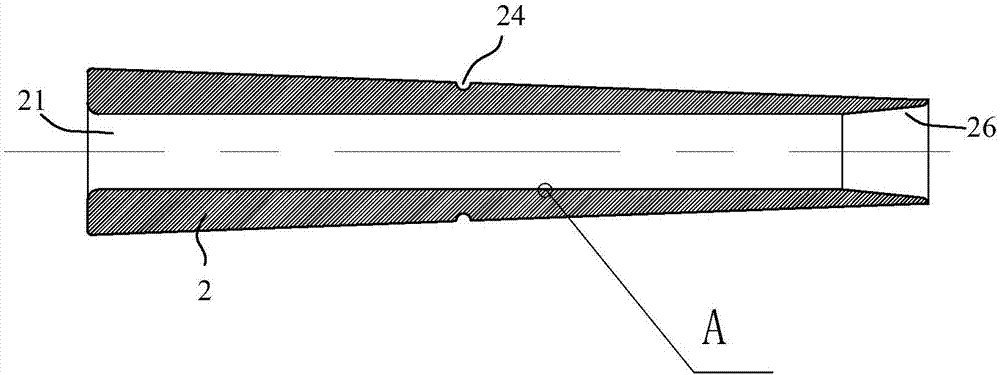

[0034] see Figure 8 , the present invention provides a wedge-shaped connecting fitting, comprising a metal sleeve 1, the metal sleeve 1 has a straight pipe section and a tapered pipe section, a wedge block 2 is provided inside the tapered pipe section, and the wedge block 2 has The outer tapered surface matched with the inner pipe wall of the tapered pipe section and the inner hole 21 through which cables can pass and be clamped. When the present invention is used, the cable 3 is passed through the inner hole 21 of the wedge block 2, the wedge block 2 is located inside the tapered pipe section, and the outer tapered surface of the wedge block 2 cooperates with the inner pipe wall of the tapered pipe section to realize the clamping of the cable 3 Tight, when two cables 3 need to be connected together, two metal sleeves 1 can be made into a whole, and two wedge-shaped blocks 2 on the front and back can be used.

[0035] Wherein, the wedge block 2 includes at least two metal ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com