Environment-friendly rebuilding and upgrading construction method for cement concrete pavement

A technology of cement concrete and construction method, applied in the directions of roads, roads, pavement details, etc., can solve problems such as affecting the use function of roads, damage, and untreated pavement cracks, so as to achieve good pavement reconstruction results, clear force transmission paths, and firm connections. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In this embodiment, the production requirements of prefabricated blocks, steel bar welding construction technology, prestressed tensioning construction operation rules, etc. will not be described in detail, and the implementation mode of green transformation and upgrading of cement concrete pavement involved in the present invention will be focused on.

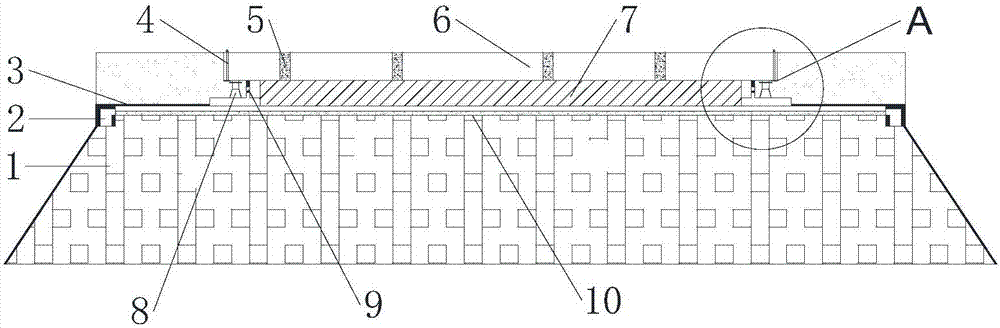

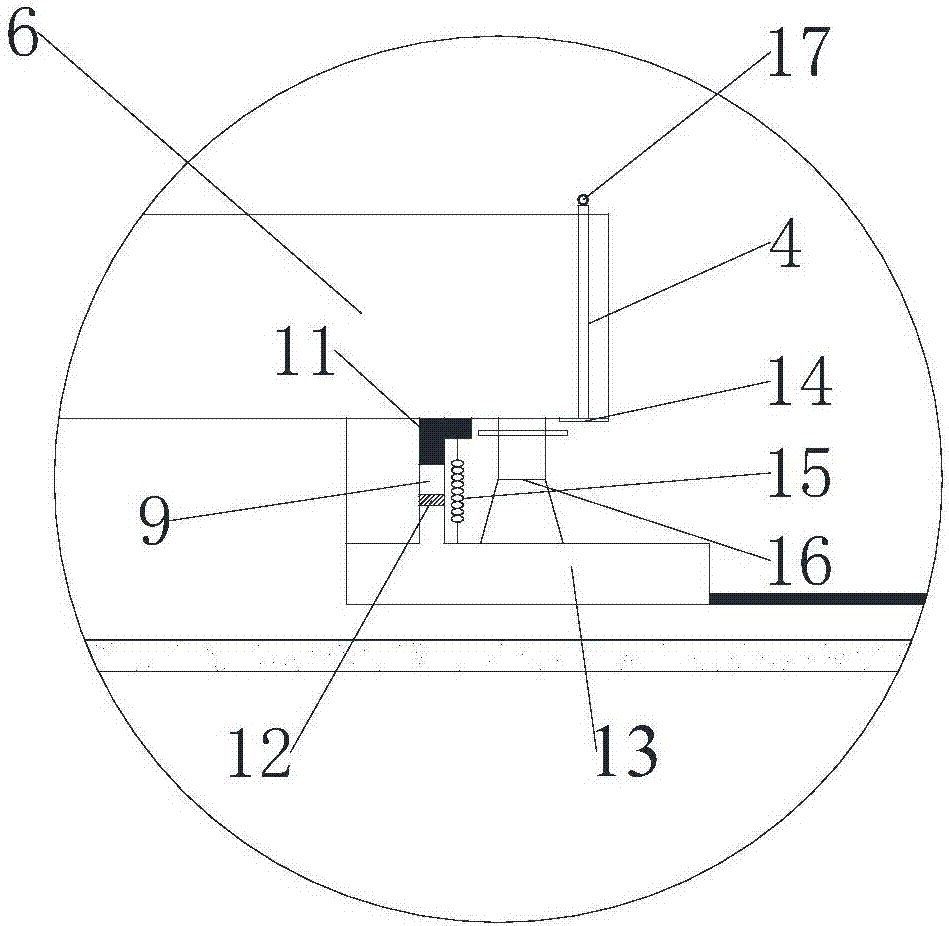

[0029] figure 1 It is a structural schematic diagram of roadbed subsidence and void treatment; figure 2 yes figure 1 Enlarged image at A in the middle; image 3 is the schematic diagram of deep fracture treatment structure; Figure 4 It is a structural schematic diagram of the leveling state of the stereotyped vibration embossing integrated device; Figure 5 It is a structural schematic diagram of the embossing state of the stereotyped vibration embossing integrated device; Figure 6 It is a construction process flow chart of the present invention.

[0030] The green transformation and upgrading structure of cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com