Square plate type air radiation device and installation mode

An installation method and air-dispersing technology, applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as resistance to strong acid and alkali, and achieve strong practicability and high oxygen utilization rate , the effect of large aeration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

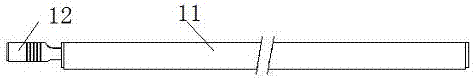

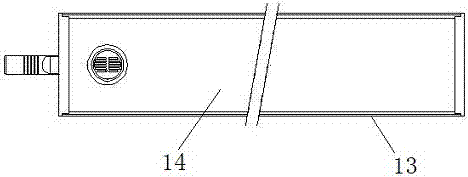

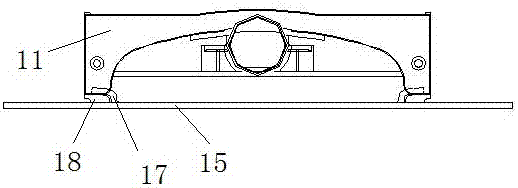

[0029] Example 1, see Figure 1 to Figure 4 , the square plate diffuser includes a square frame 13, an air connector 12 installed on the outside of the square frame 13, a diaphragm 14 located in the frame 13, the diaphragm 14 covers the space inside the entire frame, and the diaphragm 14 is EPDM diaphragm with PTFE coating.

[0030] The installation method of the square plate diffuser is connected by belt fasteners 15. The belt fasteners 15 have a symmetrical structure, and the belt fasteners 15 include two symmetrically arranged connecting pieces 16 and two fixing holes 19. , the two fixing holes 19 are respectively located on the outer sides of the two connecting pieces 16 .

[0031] Two fixing holes 19 are used to connect with the outside world, such as being installed on the ground by bolts, and two connecting pieces 16 are used to connect with the square plate type air diffuser. To support the bottom of the square plate type air diffuser, the insert block 17 is used for...

Embodiment 2

[0032] Example 2, see Figure 5 to Figure 7 , the square plate diffuser includes a square frame body 21, an air connector 22 installed inside the square frame body 21, a diaphragm 24 located in the frame body 21, the diaphragm 24 covers the space inside the entire square frame body, and the diaphragm 24 EPDM diaphragm with PTFE coating.

[0033] The installation method of the square plate diffuser is connected by a belt fastener 25. The belt fastener 25 includes two symmetrically arranged Z-shaped connectors. The lower surface of the upper end of the Z-shaped connector is fitted with a pressure block 26. The pressing block 26 presses the upper surface of the square frame body, and the lower end of the Z-shaped connector is connected with a bolt 29, and is connected with the outside through the bolt 29 for installation.

[0034] For the combination of square plate diffusers, see Figure 8 to Figure 12 .

[0035] Figure 8 The combined installation method of the Chinese squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com