Damping-variable steel wire rope torsional force release device

A release device and wire rope technology, which is applied in the field of wire rope torsional force release devices, can solve problems such as reduced rope life and mechanical properties, wire ropes cannot be released, and wire ropes are damaged, achieving light weight, low cost, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

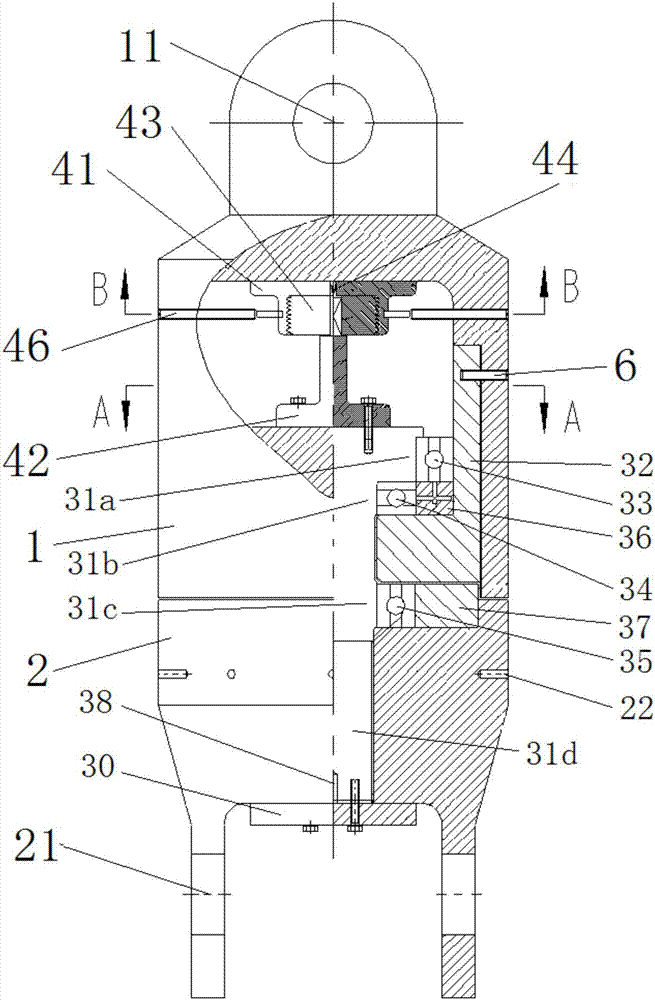

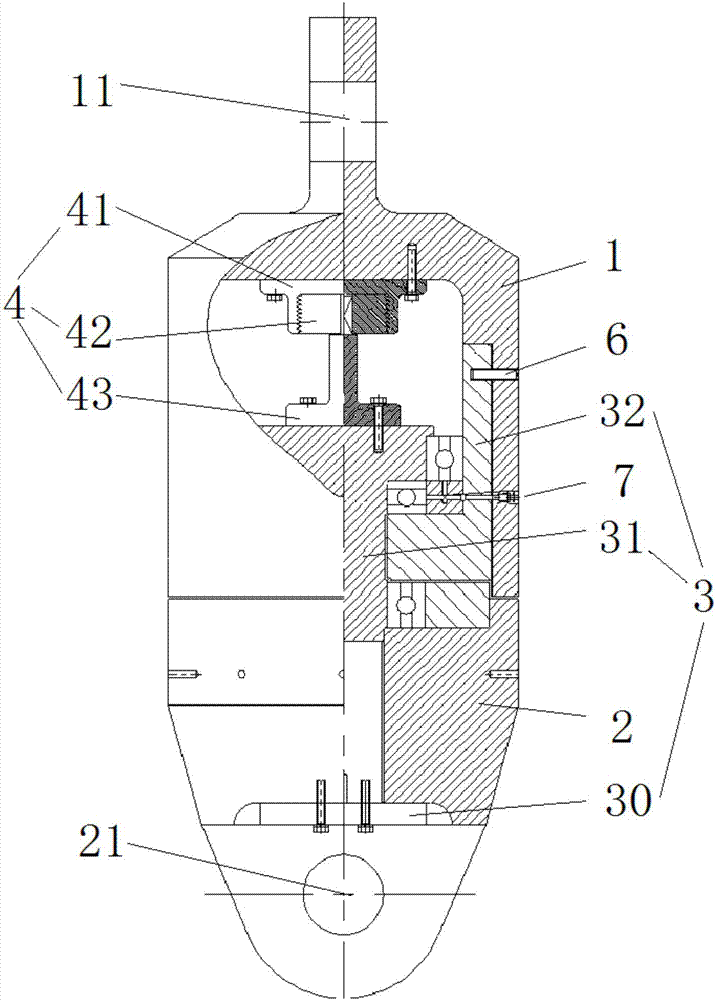

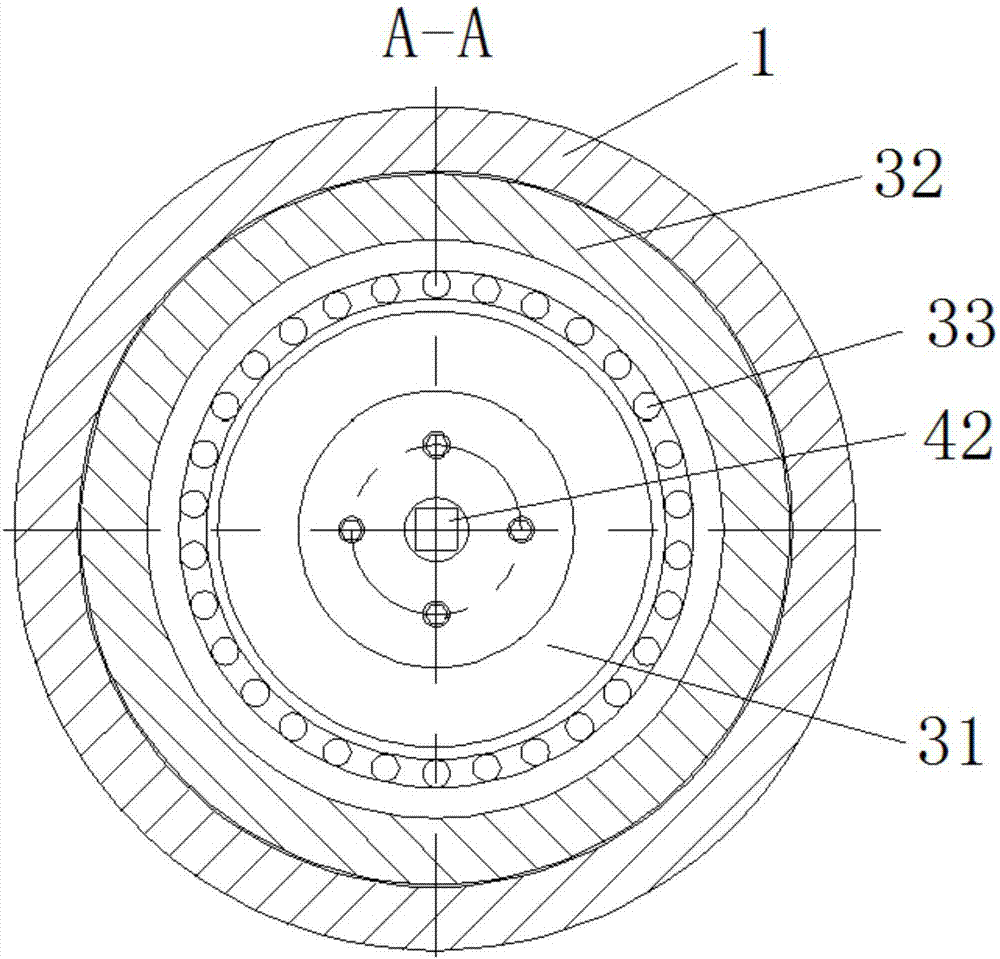

[0035] figure 1 It is a front partial cross-sectional view of the variable damping wire rope torsional force releasing device of the present invention; figure 2 Yes figure 1 Left partial sectional view of the medium variable damping wire rope torsional release device; image 3 Yes figure 1 Schematic diagram of A-A section in middle; Figure 4 Yes figure 1 Schematic diagram of the middle B-B section.

[0036] like Figure 1-4 As shown, a variable damping wire rope torsional release device includes an upper chamber casing 1, a lower chamber casing 2, an upper and lower chamber connection assembly 3, and a damping adjustment mechanism 4; the upper chamber casing 1 and the lower chamber casing The shell 2 is relatively cylindrical up and down, and the upper chamber casing 1 and the lower chamber casing 2 are connected through the upper and lower cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com