Cement mixture stirrer

A technology for mixing materials and agitators, which is applied in cement mixing devices, mixing plants, mixing operation control, etc., can solve the problems that the weight of the eccentric block cannot be very large, the operation of the whole machine is unstable, and the mixing effect is affected, and the vibration force can be achieved. Large, low cost, improve the effect of stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

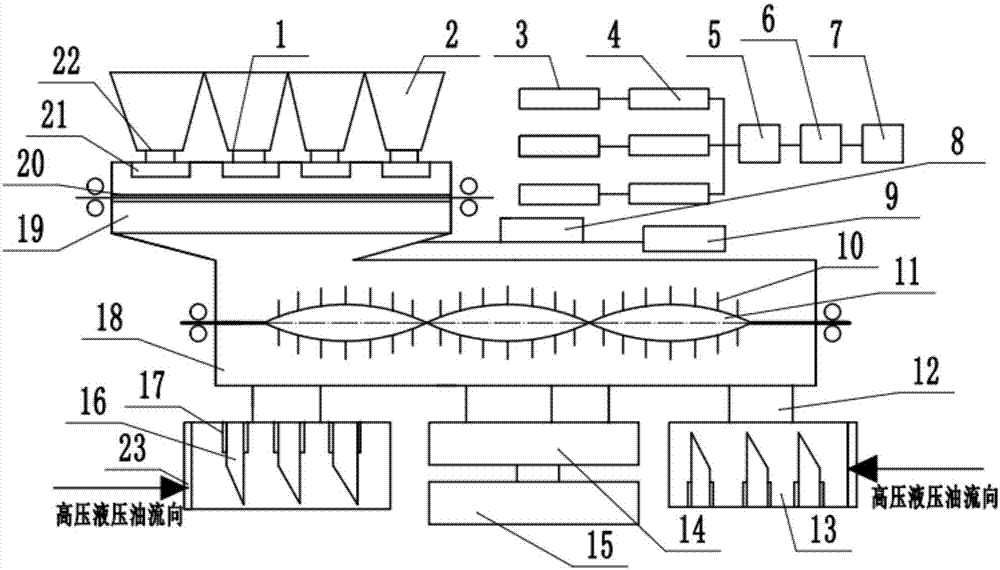

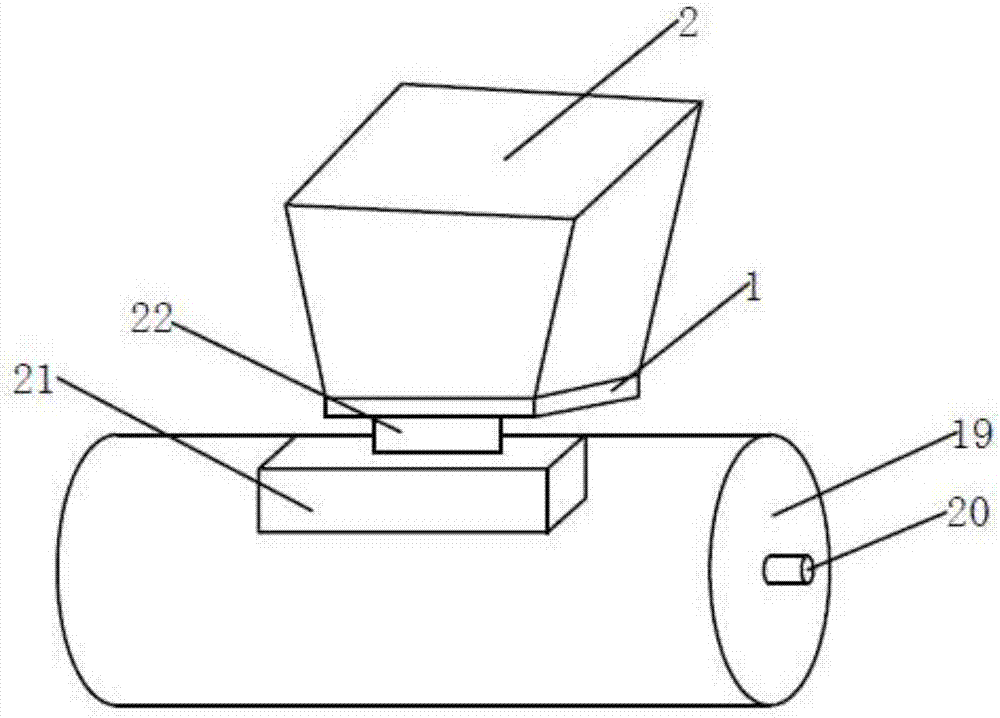

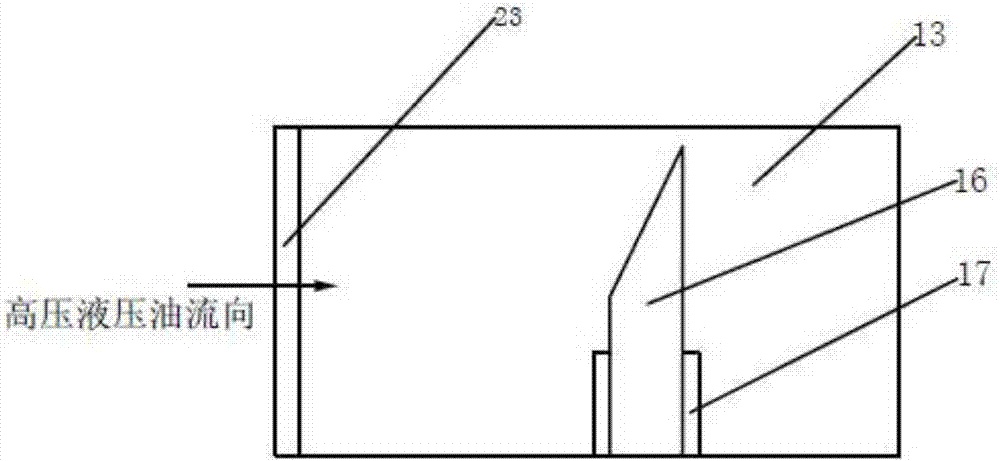

[0028] Depend on Figure 1-4 As can be seen from the shown embodiment, the present invention comprises a stone material supply device, a stirring device, a vibrating device, a vibrator coupling device 12 and a hydraulic power unit, and the stone material supply device comprises a plurality of stone material hoppers 2 set up side by side, and at the exit of each stone material hopper 2 The material opening 1 is provided with a material door switch 22, and the central connection line of the discharge opening 1 of each stone hopper 2 is located on the same horizontal line, and a rotating proportioner measured by volume is provided below each stone hopper 2: including a drum support 19 , the rotating shaft 20 of the roller bracket 19 is arranged in parallel directly below the central connection line, and each stone hopper 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com