Microwave dehydration and roasting counter-trend compensation technology and equipment for making durian chips

A technology of microwave dehydration and durian, which is applied in the direction of dehydration preservation of fruits/vegetables, food science, etc. It can solve the problems of dry and hard taste, unsightly appearance, and reduce the attractiveness of durian chips, so as to achieve the effect of crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

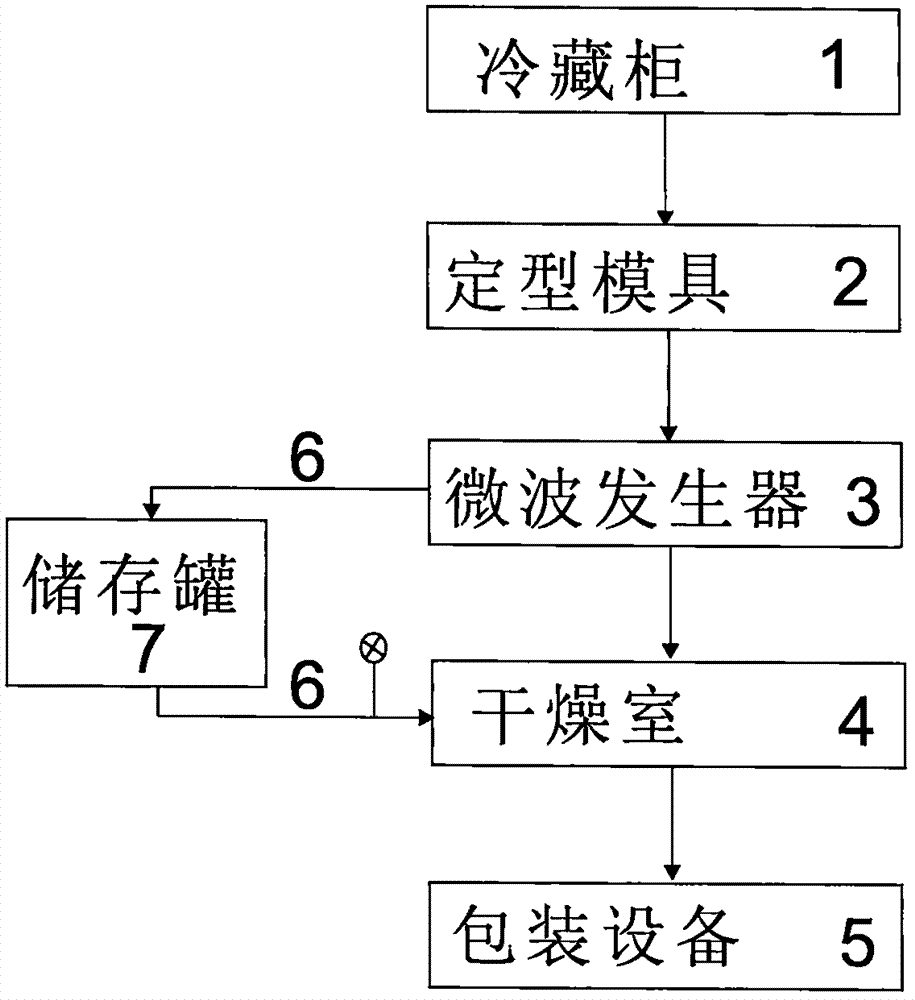

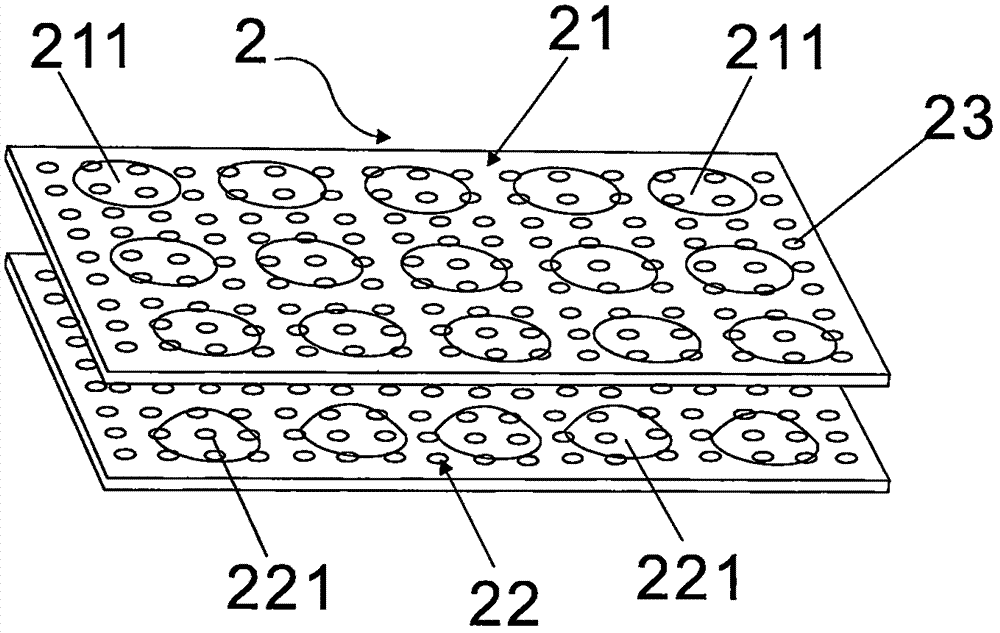

[0029] Such as figure 1 and figure 2 Shown a kind of equipment of making durian chips, comprise refrigerated cabinet 1, shaping mold 2, microwave dehydrator 3, drying chamber 4 and packaging equipment 5, described shaping mold 2 is covered with the upper die 21 of through hole 23 Consists of a lower die 22, the upper die 21 is provided with a notch 211 corresponding to the shape of the durian slices, the lower die 22 is provided with a protrusion 221 corresponding to the shape and size of the notch 211, and a recovery tray is provided below the shaping die 2 Specifically, the shaping die 2 adopts two corresponding upper and lower sheet members, which can also be said to be two sheet-like upper and lower dies, and the sheet members are covered with through holes. The openings 211 are respectively distributed on the upper and lower sheet-like components, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com