Composite stranding high-speed wire-stranding machine

A twisting machine and composite twisting technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as unsatisfactory twisting effects, difficulty in ensuring product quality, messy twisting of wire cores, etc., and achieve structural The effect of ingenious design, improvement of enterprise competitiveness, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

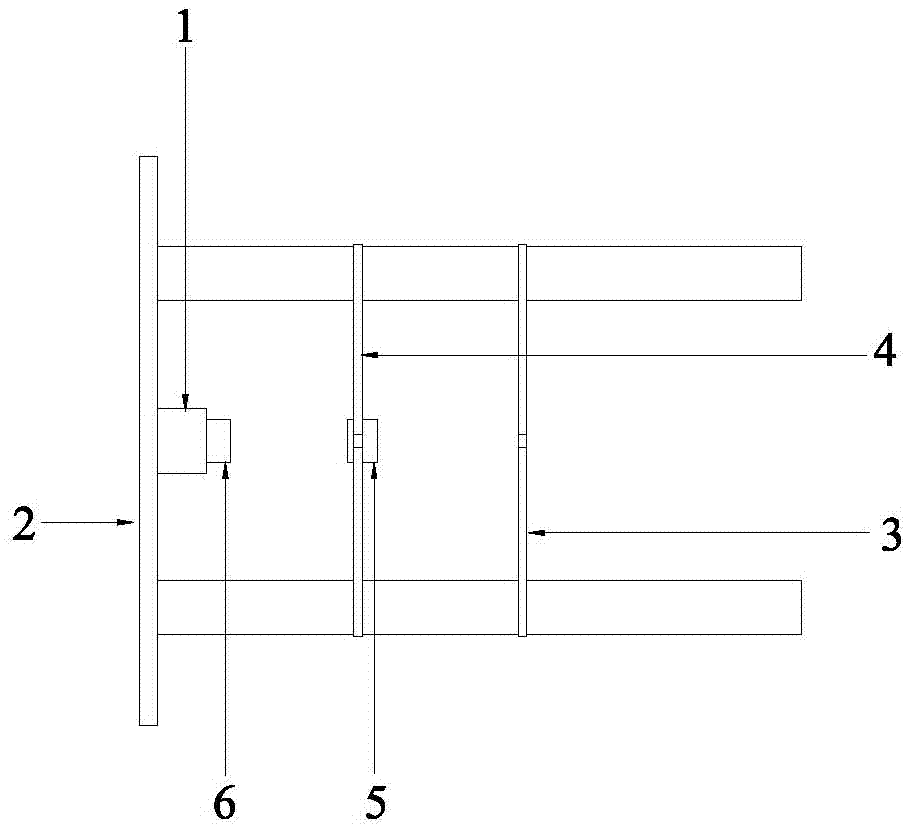

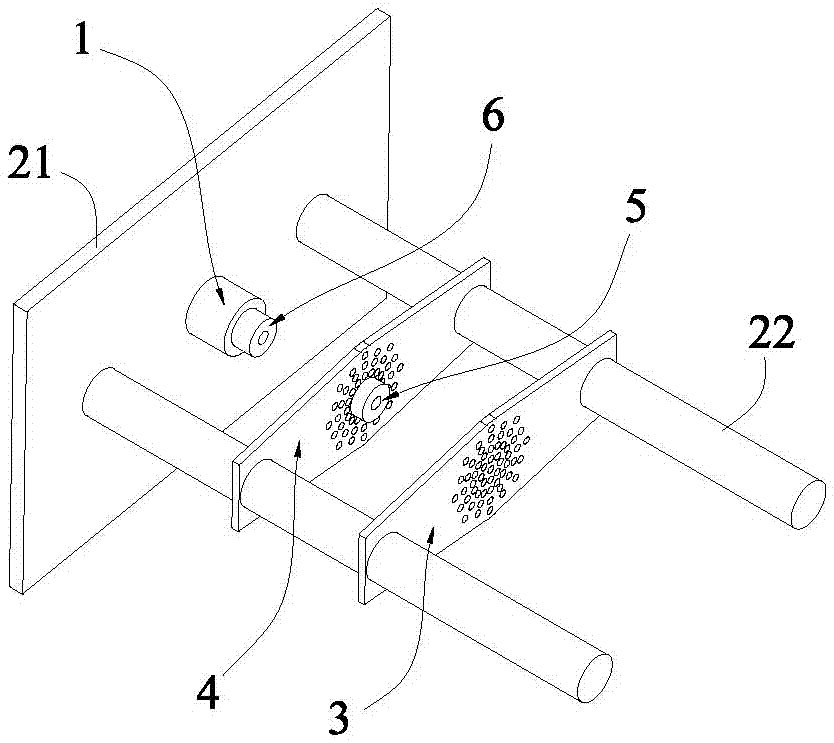

[0014] Example: see figure 1 with figure 2 , The embodiment of the present invention provides a composite stranding high-speed stranding machine, which includes a stranding host, a mounting frame 2, a front splitter board 3, a rear splitter board 4, a first stranding mold 5, and a second stranding mold 6. The mounting frame 2 is arranged near the stranding port 1 of the stranding host, and the rear splitting board 4 and the front splitting board 3 are sequentially spaced from near the stranding port 1 to the farthest. Is arranged on the mounting frame 2, the center position of the front wiring board 3 is radially distributed with a plurality of front wiring holes, and the first stranding mold 5 is set at the center position of the rear wiring board 4, A plurality of rear splitting holes are distributed radially around the first stranding mold 5, and the second stranding mold 6 is arranged on the stranding opening 1. In order to improve the arrangement and distribution effect,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com