Performance evaluation method and system for flame-retardant material for secondary cell

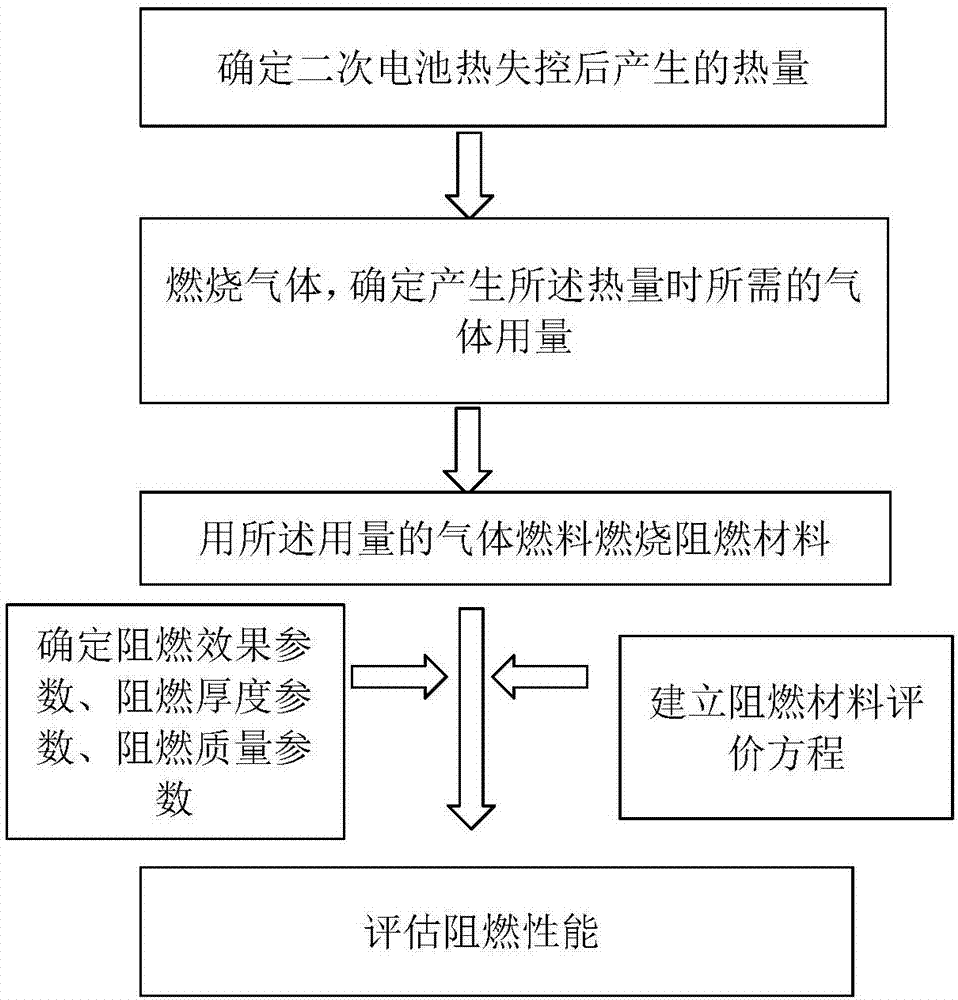

A technology of flame retardant materials and secondary batteries, applied in the field of electrochemical power supply and energy storage, can solve the problems of large thickness and weight of flame retardant materials, waste of materials, and large space occupied by flame retardant materials, so as to reduce the volume fraction and Parts by mass, reducing the risk factor, and improving the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0121] (1) Under the current rate of 1C, adjust the SOC state of charge of the secondary battery without flame retardant material to 100% with a battery charge and discharge meter, and weigh m 0 =234g;

[0122] (2) In the "mCp" mode, use an adiabatic acceleration calorimeter to measure the specific heat capacity Cp of the secondary battery without flame retardant materials 0 =1.0121J(g·k) -1 ;

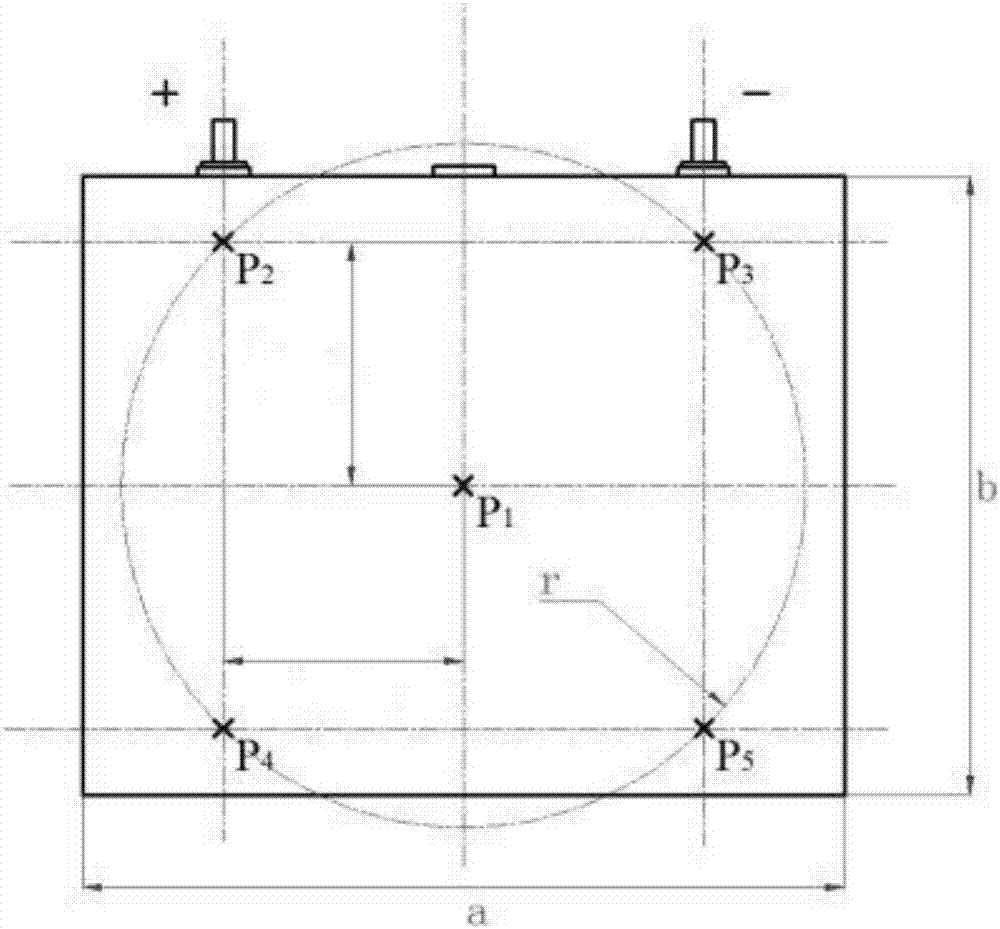

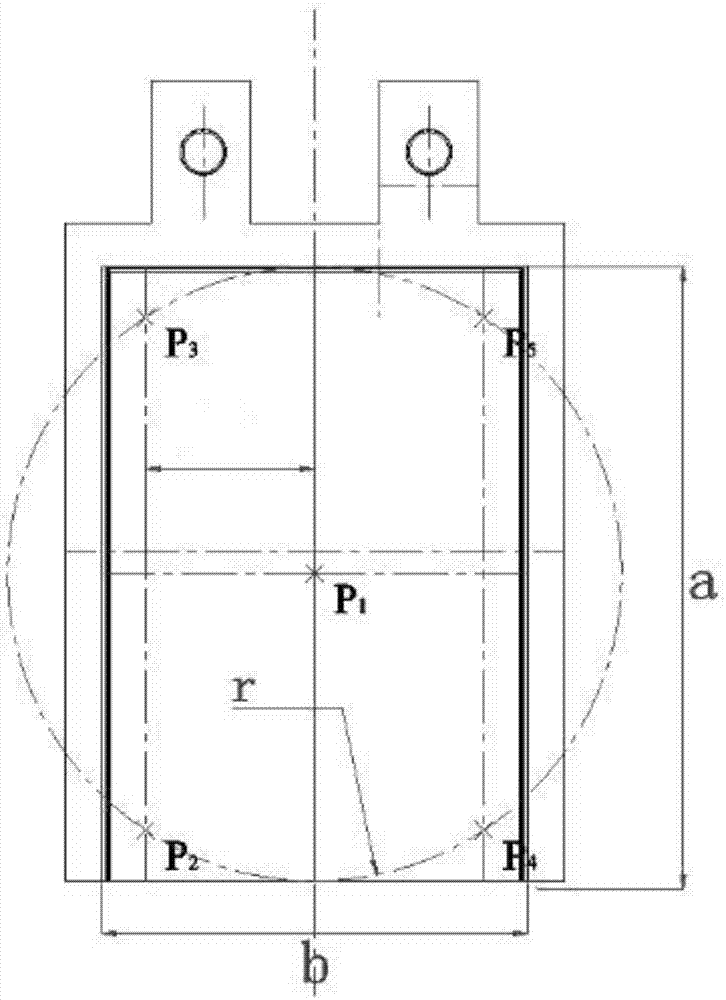

[0123] (3) Set 5 temperature sensors on the surface of the secondary battery without flame retardant materials, corresponding to 5 points on the secondary battery: P1-P5; P1 is the center of one side (ab side) of the battery, P2 , P3, P4 and P5 are respectively located on the circle with P1 as the center and R=35mm as the radius, P2: (-20,22), P3: (20,22), P4: (-20,-22), P5: (20,-22); P1-P5 points correspond to the measured temperature as T1-T5, Tm=max(T1, T2, T3, T4, T5);

[0124]Overcharge the secondary battery at a current rate of 2C in an adiabatic environment, the temperature ...

example 2

[0144] (1) Under the current rate of 1C, adjust the SOC state of charge of the secondary battery without flame retardant material to 100% with a battery charge and discharge meter, and weigh m 0 =457g;

[0145] (2) In the "mCp" mode, use an adiabatic acceleration calorimeter to measure the specific heat capacity Cp of the secondary battery without flame retardant materials 0 =1.3827J(g·K) -1 ;

[0146] (3) Set 5 temperature sensors on the surface of the secondary battery without flame retardant materials, corresponding to 5 points on the secondary battery: P1-P5; P1 is the center of one side (ab side) of the battery, P2 , P3, P4 and P5 are respectively located on the circle with P1 as the center and R=40mm as the radius, P2: (-33,50), P3: (33,50), P4: (-33,50), P5 : (33,-50); P1-P5 points correspond to the measured temperature as T1-T5, Tm=max(T1, T2, T3, T4, T5);

[0147] Overcharge the secondary battery at a current rate of 2C in an adiabatic environment, the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com