High-power fiber laser safety monitoring method and device

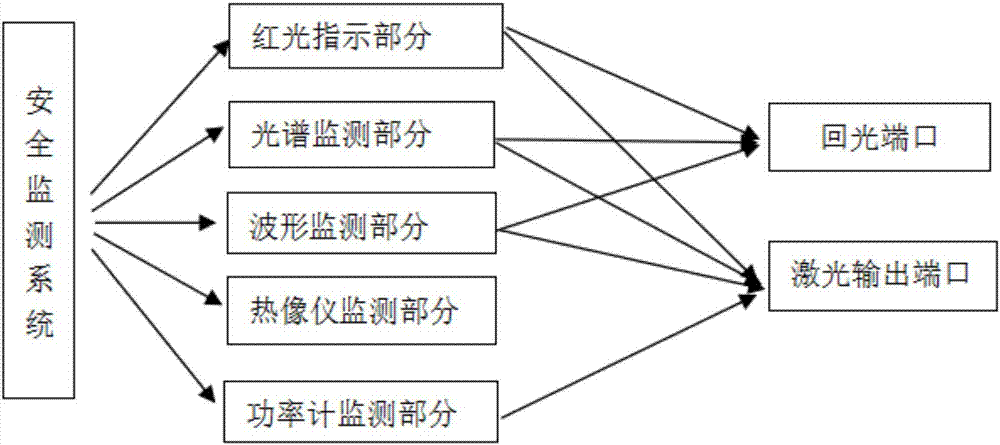

A fiber laser, safety monitoring technology, used in measuring devices, optical instrument testing, machine/structural component testing, etc. It can solve the problem that the internal temperature is difficult to observe, the surface temperature cannot be predicted in advance, and the power meter cannot accurately reflect the power Slight fluctuations and other problems, to achieve scientific and reasonable judgment and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Such as figure 1 As shown, in order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

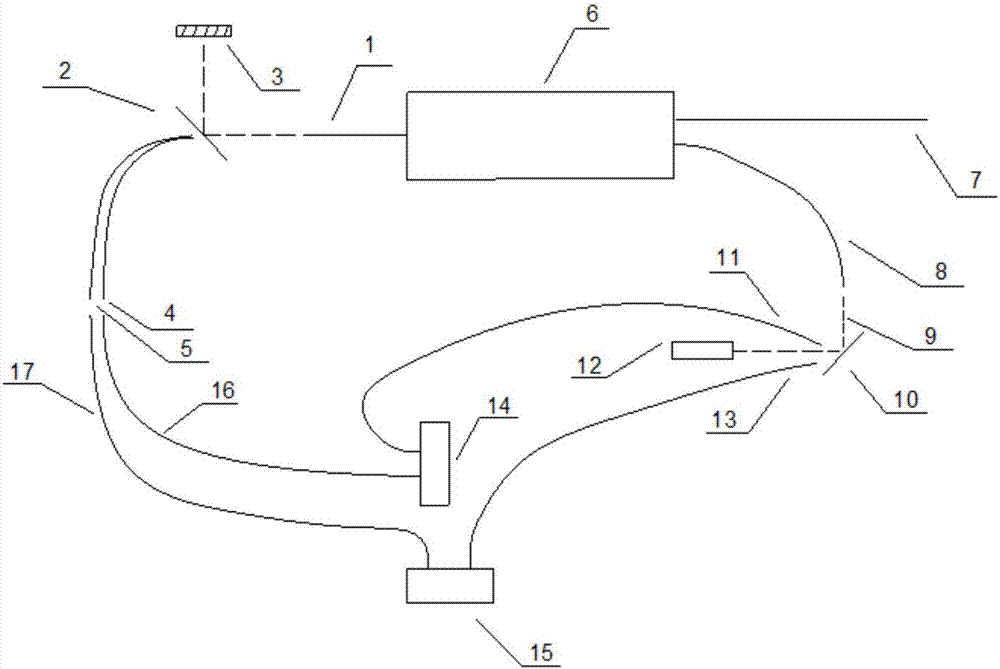

[0039] The implementation mode of the high-power fiber laser safety monitoring method in the embodiment of the present invention is as follows:

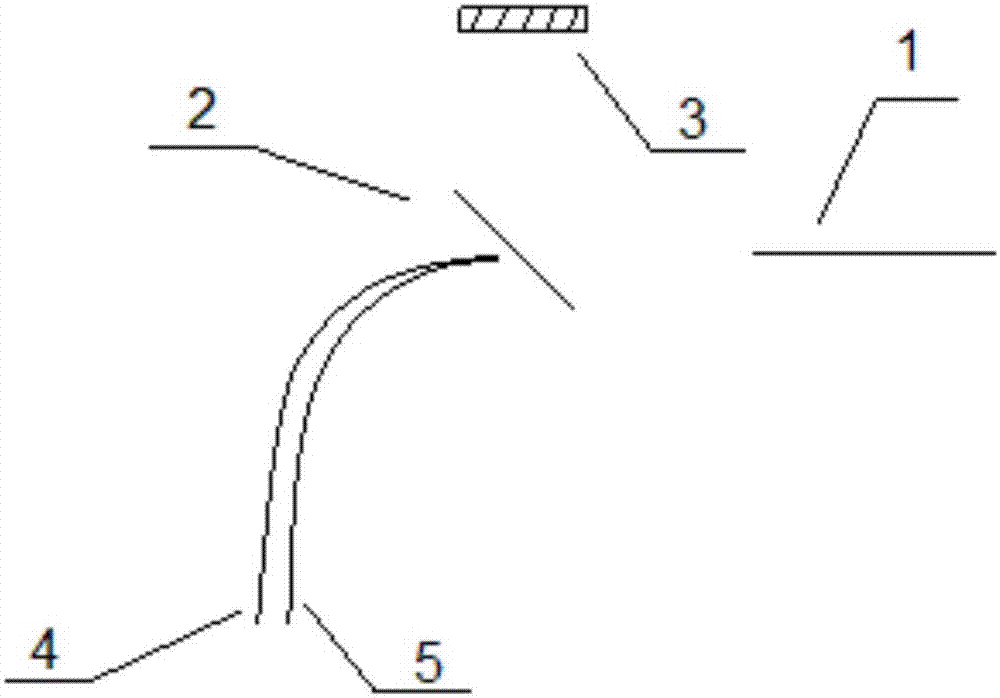

[0040] First build the monitoring channel at the output end, such as figure 1 As shown, 1 is the output fiber, 2 is the high reflective mirror with high reflection rate to the laser (99.5%-99.95%), 3 is the power meter, the output laser is output from 1, and most of it enters the power meter through the high reflective mirror. Only a very small part of the light is transmitted through 2 and enters the coreless optical fibers 4 and 5 (ie, the monitoring channel). Coreless fibers 4 and 5 need to be as close as possible to receive enough signal light.

[0041] The next step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com