Buffering regulation mechanism for roller of suction plate

A buffer adjustment and roller technology, applied in the field of road sweepers, can solve the problems of labor and time, shortened service life, and wear of rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

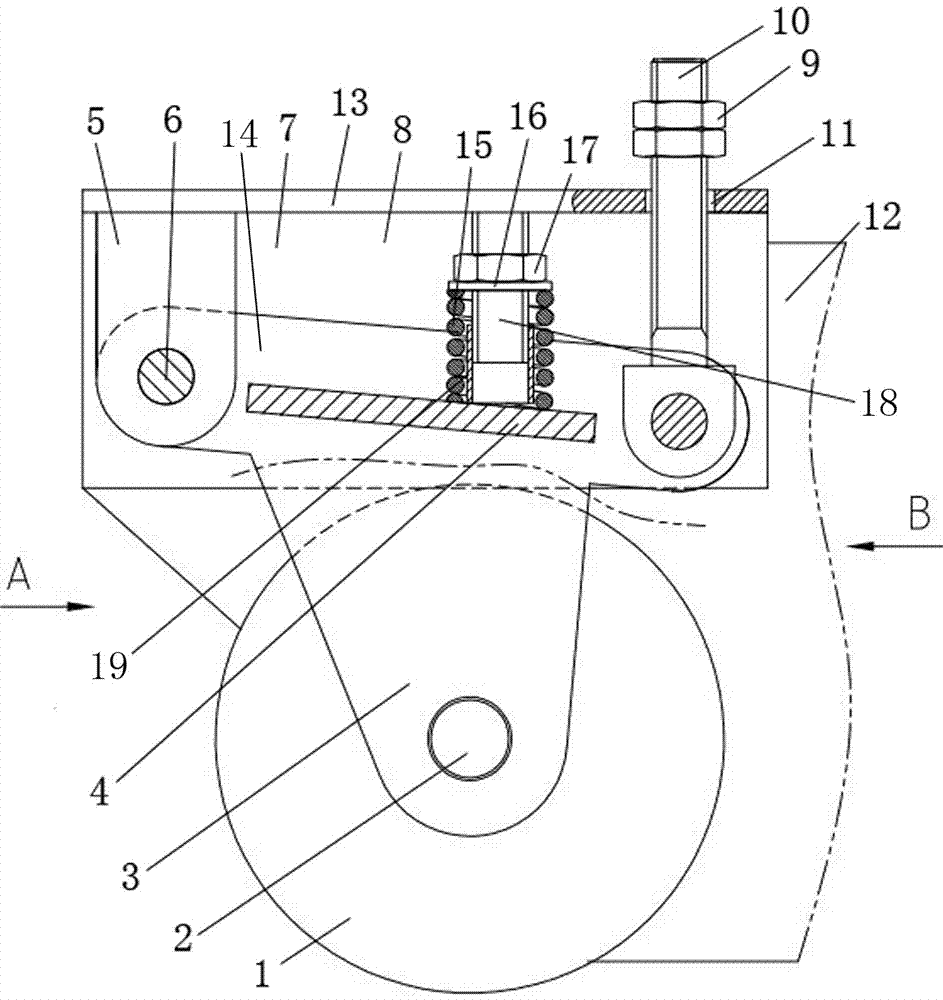

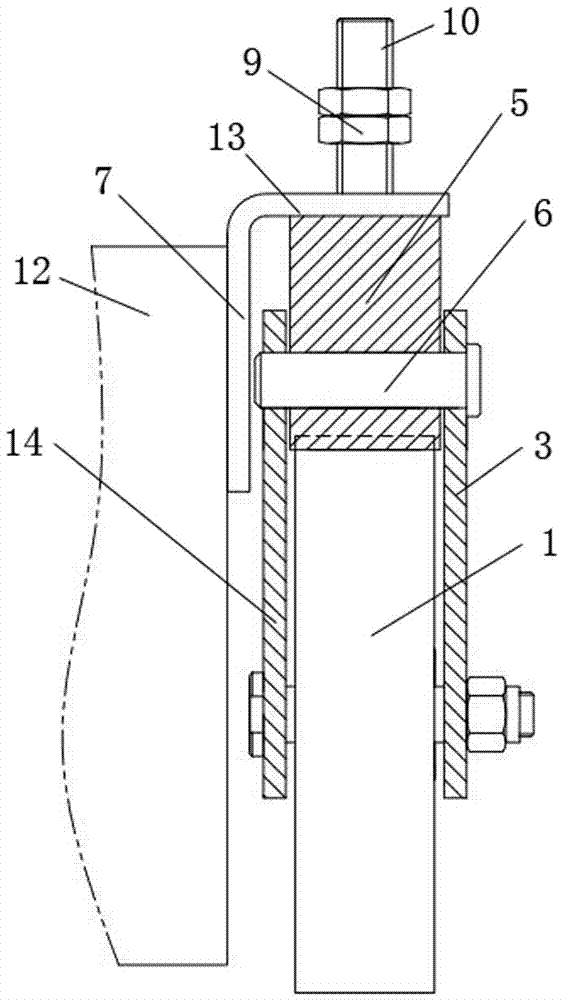

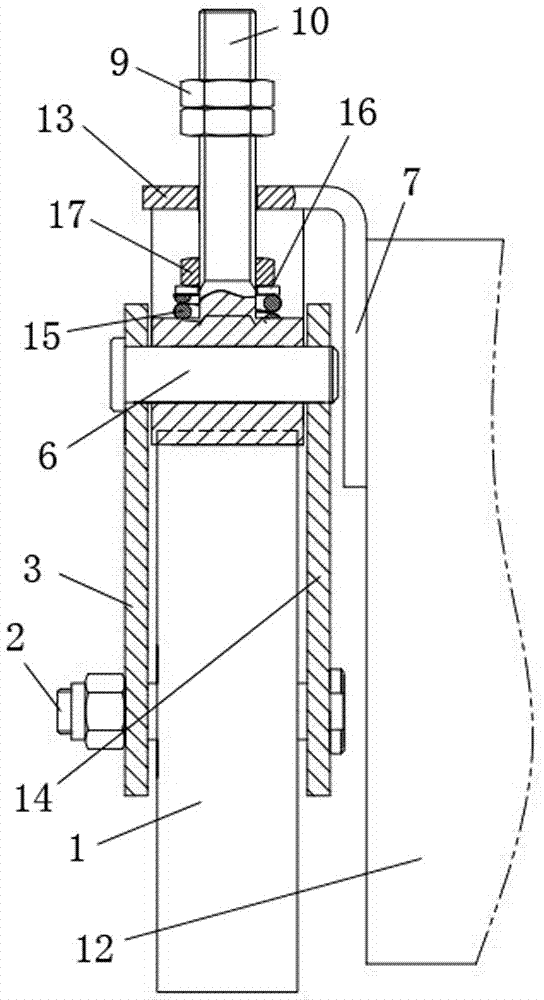

[0010] figure 1 , figure 2 and image 3 Among them, the present invention discloses a suction cup roller buffer adjustment mechanism, which includes a roller 1, a roller bracket, an adjusting bolt 10, a fixing seat 8, a connecting seat 5, a supporting bolt 18, a spring 15 and a guide sleeve 19. The fixing seat is an angle steel structure including a top surface 13 and a side surface 7 . The upper end of the connecting seat 5 is arranged below the front part of the top surface 13 of the fixing seat 8 . Described roller support comprises side plate one 3 and side plate two 14, and side plate one 3 and side plate two 14 have the same structure. Roller 1 is contained in the inner lower part between side plate one 3 and side plate two 14 by lower bearing pin 2. The bottom of connecting seat 5 is contained in the upper front part between side plate one 3 and side plate two 14 by bearing pin 6. The lower end of the adjusting bolt 10 is positioned at the upper rear portion betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com