A kind of silicone wax emulsion and preparation method thereof

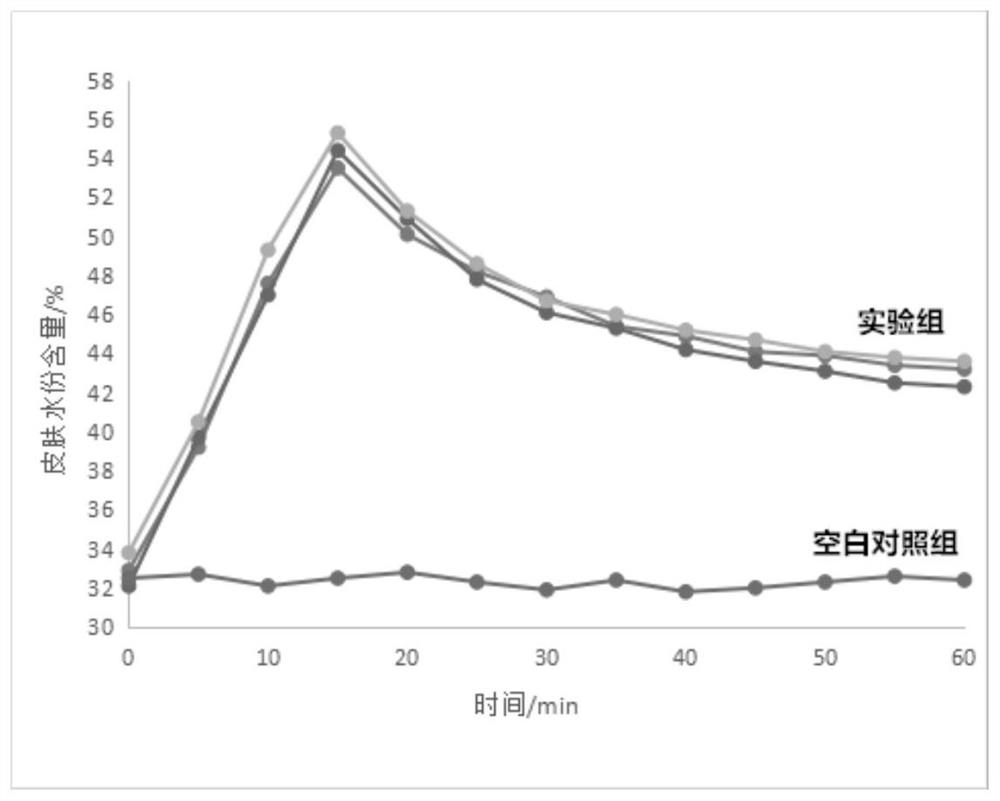

A silicone wax and emulsion technology, which is applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of the gap between the research and application level of silicone wax, backward production technology, and backward process conditions, and achieve high moisturizing effect. The effect of skin affinity, stable product status and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Mix D4H and hydrogen-terminated silicone oil (molecular weight: 2000, purchased from Tianjin Zhiyuan Chemical Reagent Co., Ltd.) at a molar ratio of 5:1, react at 85°C for 5h under the action of catalyst sulfonated cationic resin, and distill under reduced pressure at 135°C , and filtered to obtain a hydrogen-terminated silicone oil containing active hydrogen in the side chain.

Embodiment 2

[0063] The hydrogen-terminated silicone oil containing active hydrogen in the side chain prepared in Example 1 was mixed with 1-octadecene at a molar ratio of 1:3, under the action of catalyst chloroplatinic acid, hydrosilylation reaction, and then vacuum distillation, Obtained octadecyl silicone wax.

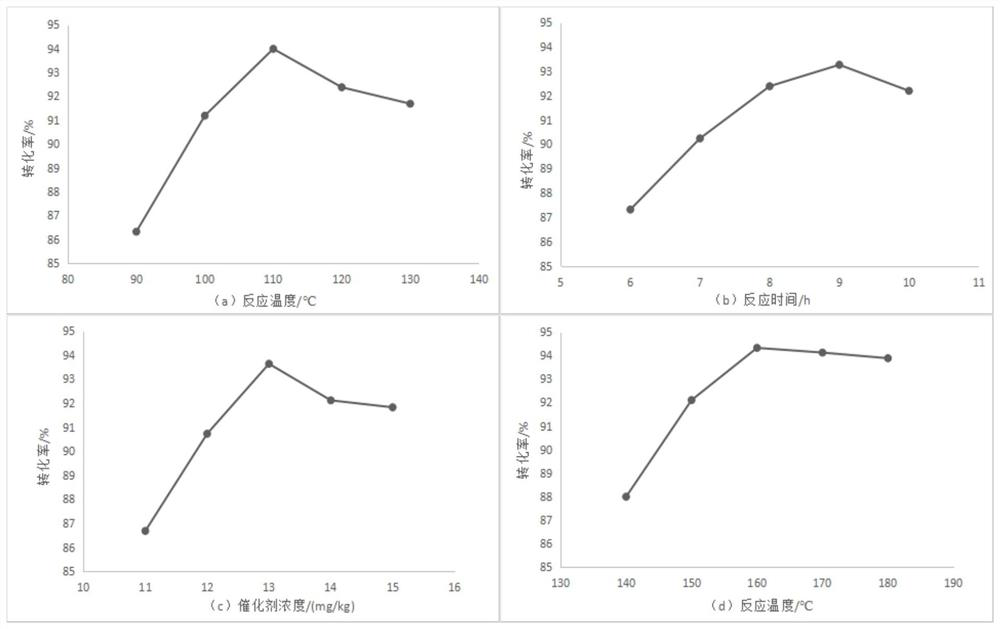

[0064] When the hydrosilylation reaction time is 5h, the concentration of the catalyst chloroplatinic acid in the reaction system is 13mg / kg, and the vacuum distillation temperature is 150°C, the relationship between the hydrosilylation reaction temperature and the conversion rate is as follows figure 1 As shown in a, from figure 1 a It can be seen that the reaction conversion reaches the highest at 110 °C.

[0065] When the hydrosilylation reaction temperature is 130°C, the concentration of the catalyst chloroplatinic acid in the reaction system is 13 mg / kg, and the vacuum distillation temperature is 150°C, the relationship between the hydrosilylation reaction time and the co...

Embodiment 3

[0069] The hydrogen-terminated silicone oil containing active hydrogen in the side chain prepared in Example 1 is mixed with 1-octadecene according to a molar ratio of 1:3, and the catalyst chloroplatinic acid (the concentration of chloroplatinic acid in the reaction system is 12mg / kg ) under the action of hydrosilylation reaction at 110°C for 9h, and then vacuum distillation at 140°C to obtain octadecyl silicone wax.

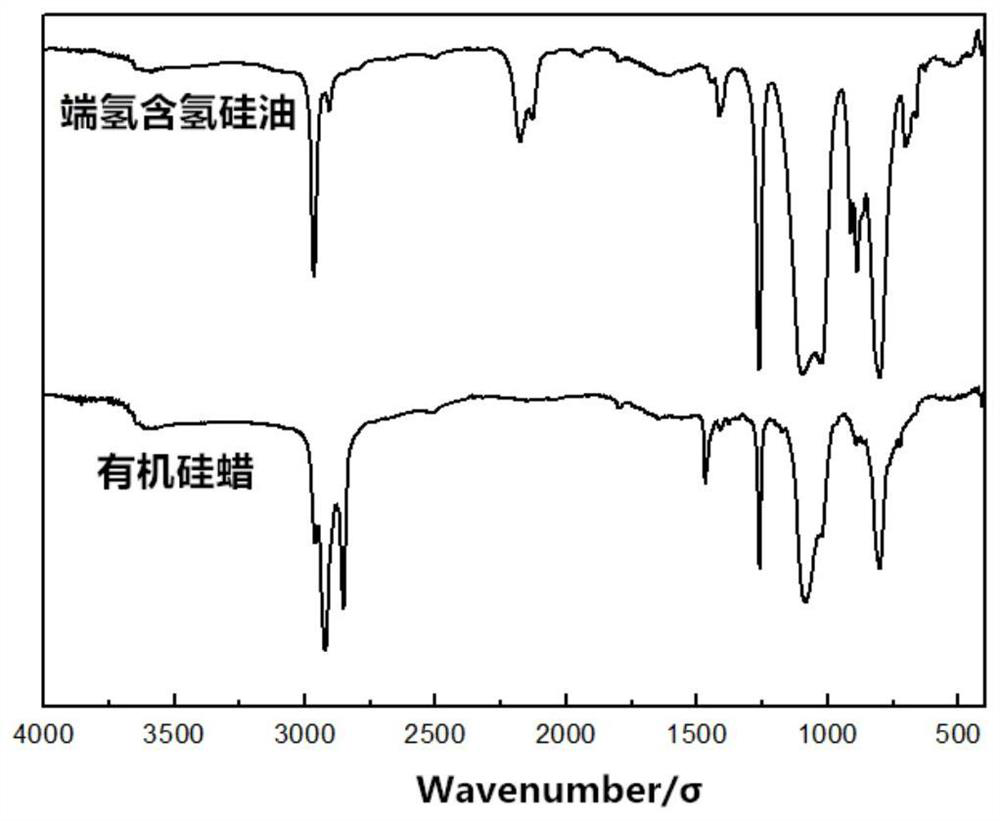

[0070] figure 2 Infrared spectra of hydrogen-terminated silicone oil and octadecyl silicone wax containing active hydrogen in the side chain. Depend on figure 2 It can be seen that the hydrogen-terminated silicone oil containing active hydrogen in the side chain is at 2178 and 889cm -1 There are two strong absorption peaks at , which are the stretching vibration peak and deformation vibration peak of the silicon-hydrogen bond. After the reaction, the disappearance of these two absorption peaks in the octadecyl silicone wax indicates that the silicon-hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com