Automatic cover opening device and pressure container tank with same

A technology of automatic cover opening and cover body, which is applied in the disassembly of threaded caps and finger-shaped grappling hook disassembly, etc., can solve the problems of large labor force, low labor efficiency, poor safety and reliability, etc., so as to reduce labor intensity and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

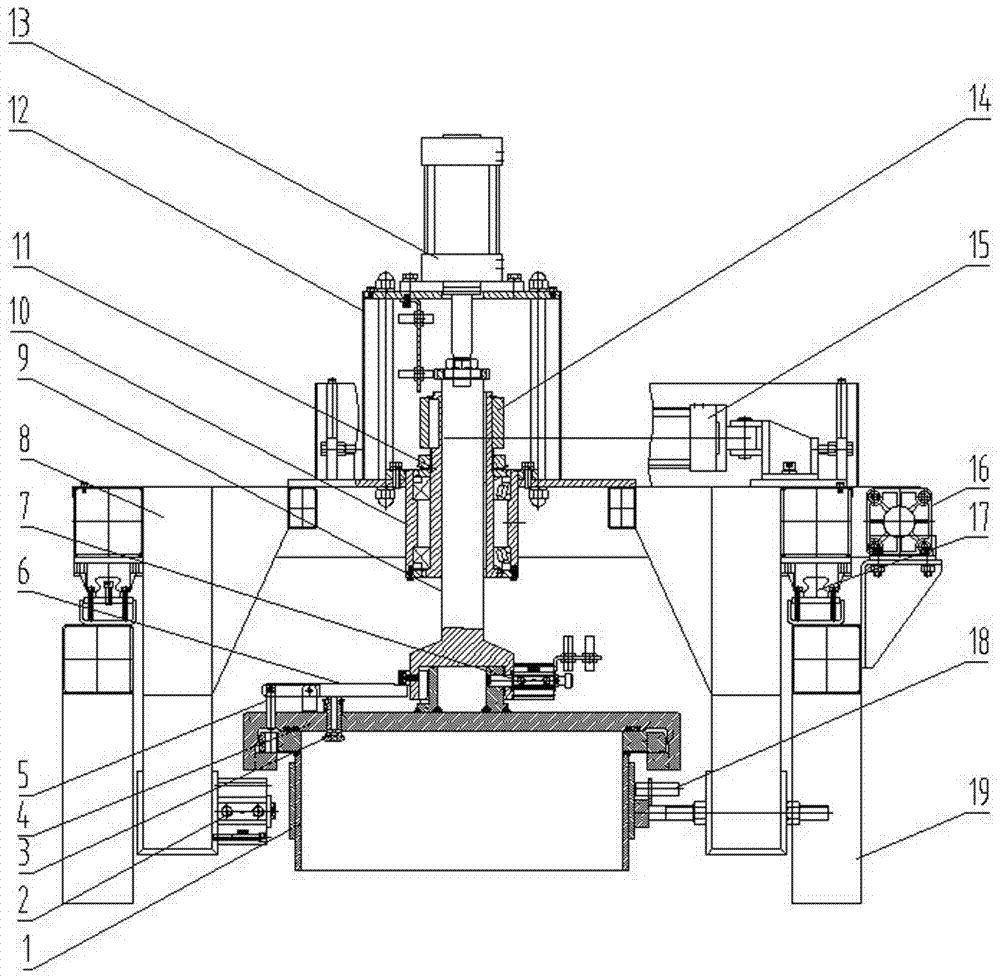

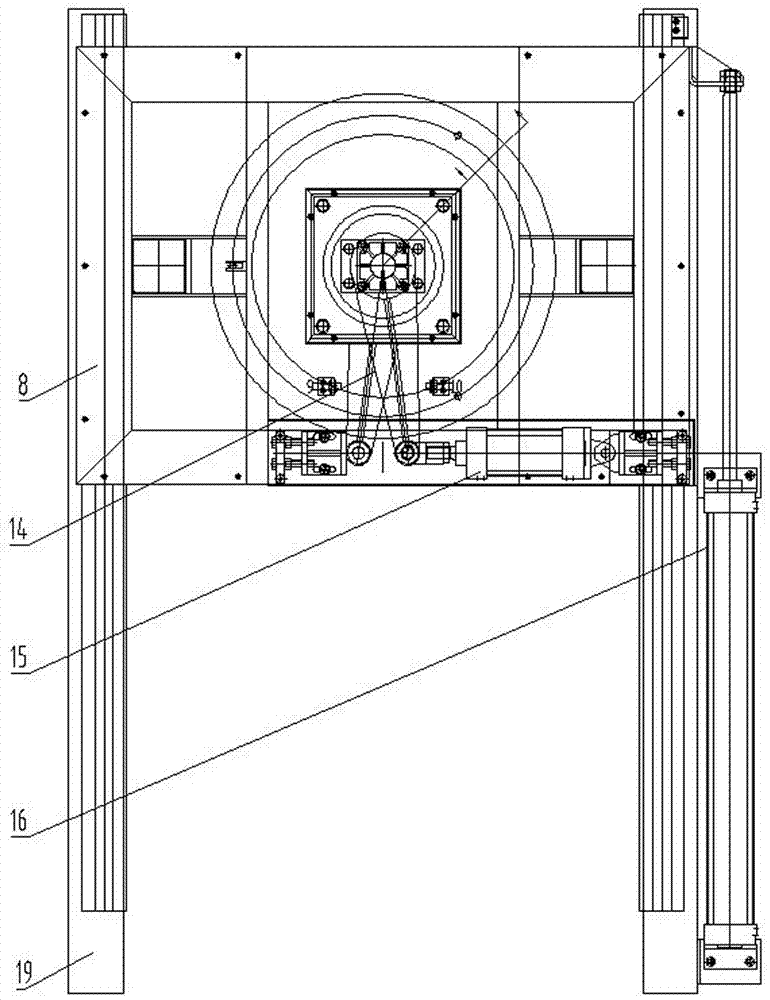

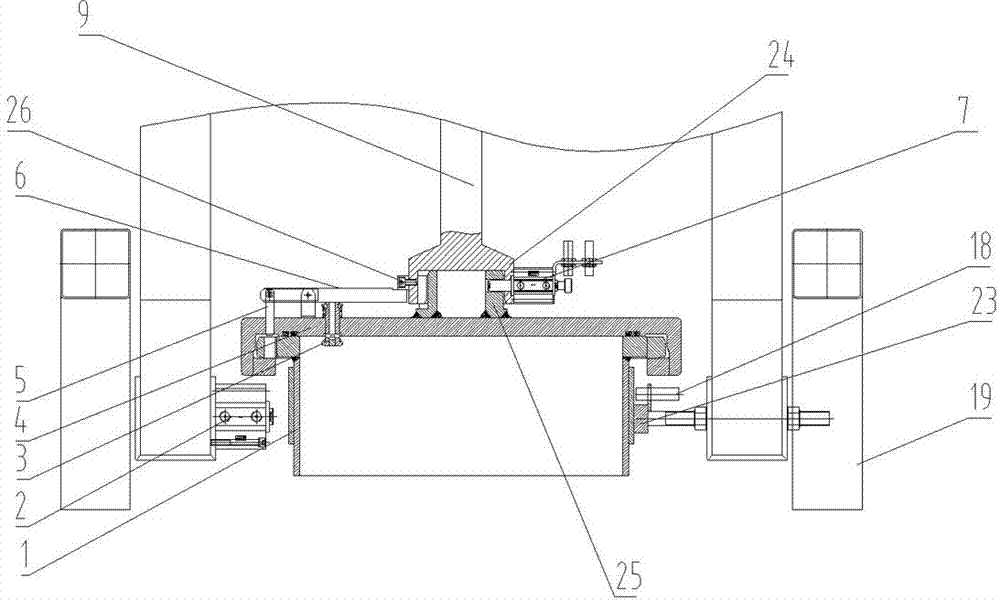

[0026] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0027] Figure 1-6 Shown is an automatic cover opening device provided by the present invention and a pressure container tank using the cover opening device, including a tank body 1, a positioning cylinder 2, an exhaust valve core 3, a cover body 4, a positioning pin 5, a lever 6. Fixed cylinder 7, mobile mounting frame 8, lifting and rotating positioning rod 9, bearing seat 10, positioning sleeve 11, driving mechanism mounting frame 12, driving mechanism 13, rotating arm 14, cylinder 15, telescopic cylinder 16, slide rail 17, The detector 18 , the fixing frame 19 , the compression spring 20 , the ring sleeve 21 , the flange 22 , the second outer ring gear 221 and the second inner ring gear 41 .

[0028] An automatic cover opening device, comprising a lifting and rotating positioning rod 9; the lower end of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com