Feeding and box opening device and method for packaging boxes

A technology for packaging boxes and feeding materials, applied in packaging and other directions, can solve the problems of reduced production efficiency, the use of a lot of manpower, and the inability of labor to work for a long time, so as to improve work efficiency and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0026] A packaging box feeding and unpacking device disclosed by the present invention can automatically realize packaging box feeding and packaging box opening, improve production efficiency and save production cost.

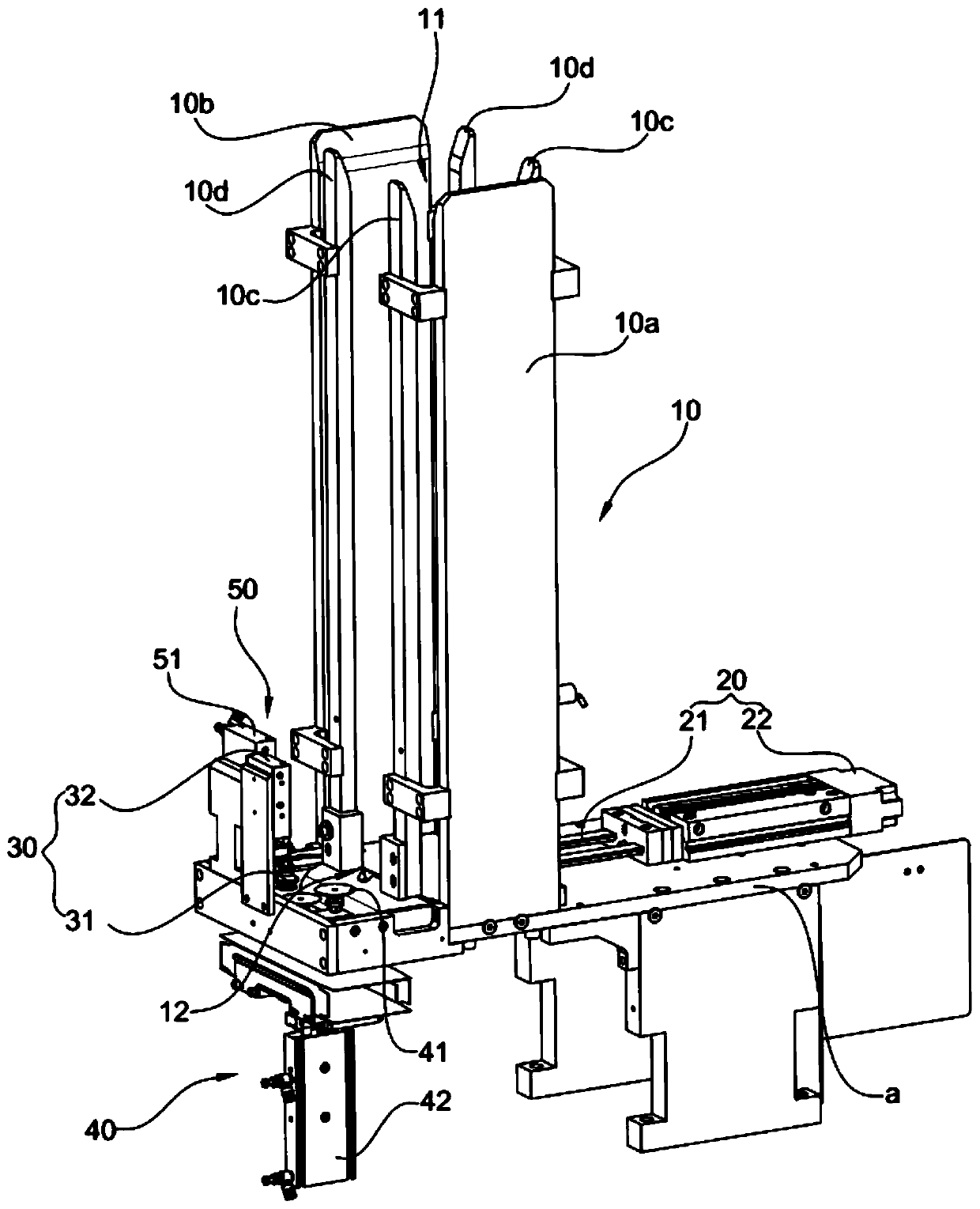

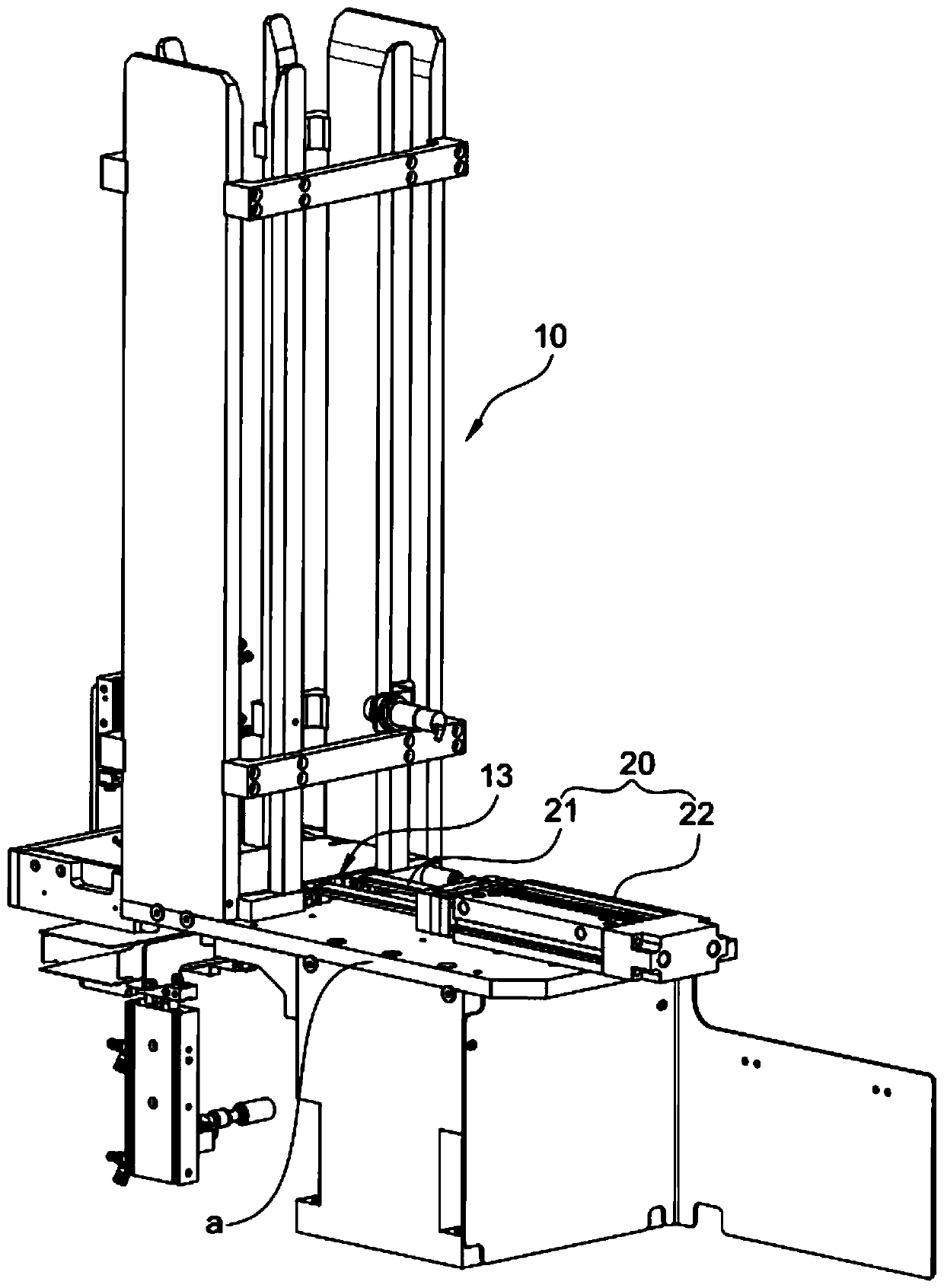

[0027] like figure 1 As shown, a packaging box feeding and unpacking device disclosed in the present invention includes a storage bin 10, a push mechanism 20, a first adsorption mechanism 30 and a second adsorption mechanism 40, wherein the storage bin 10 is located at the working On the table a, it is used to store the packaging boxes folded in sheets; the push mechanism 20 is also installed on the workbench a, and is set close to the storage bin 10, and is used to remove the packaging boxes folded in sheets from the storage bin 10 is pushed out to the box-opening st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com