Air floating type film guiding device on preparation equipment of conductive film

A conductive film, air-floating technology, used in thin material handling, transportation and packaging, winding strips, etc., can solve problems such as film deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

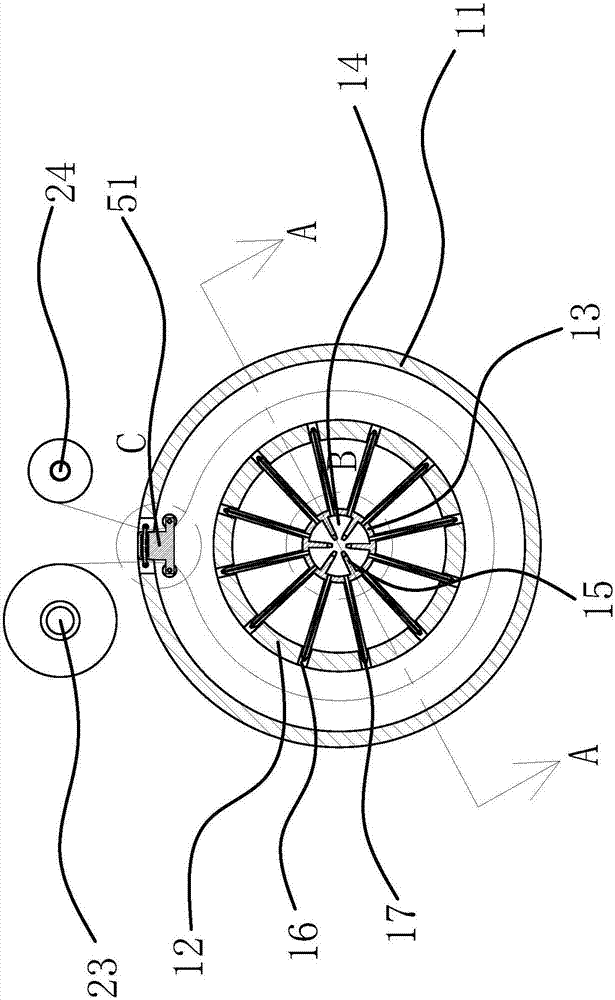

[0028] Such as figure 1 with figure 2 As shown, the preparation equipment includes a sputtering machine, and the sputtering machine includes a cylindrical housing 11, the two ends of the housing 11 have openings, and a hollow installation cylinder 12 is arranged in the housing 11, and a hollow installation cylinder 12 is arranged in the installation cylinder 12. There is a rotating shaft 13, which is connected with the output shaft of a motor. The rotating shaft 13 is a hollow structure. There is a ventilation chamber 14 in the rotating shaft 13. Several partitions 15 are uniformly arranged on the inner wall of the ventilation chamber 14. The outer ends of each partition 15 It is fixedly connected with the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com