Pallet trolley multi-station conveying system

A conveying system, multi-station technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of increasing the area of the assembly line and the configuration cost of the assembly line, the equipment cannot be reused, and the reverse flow cannot be achieved. Improve equipment utilization, shorten the length of the assembly line, and adjust the transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

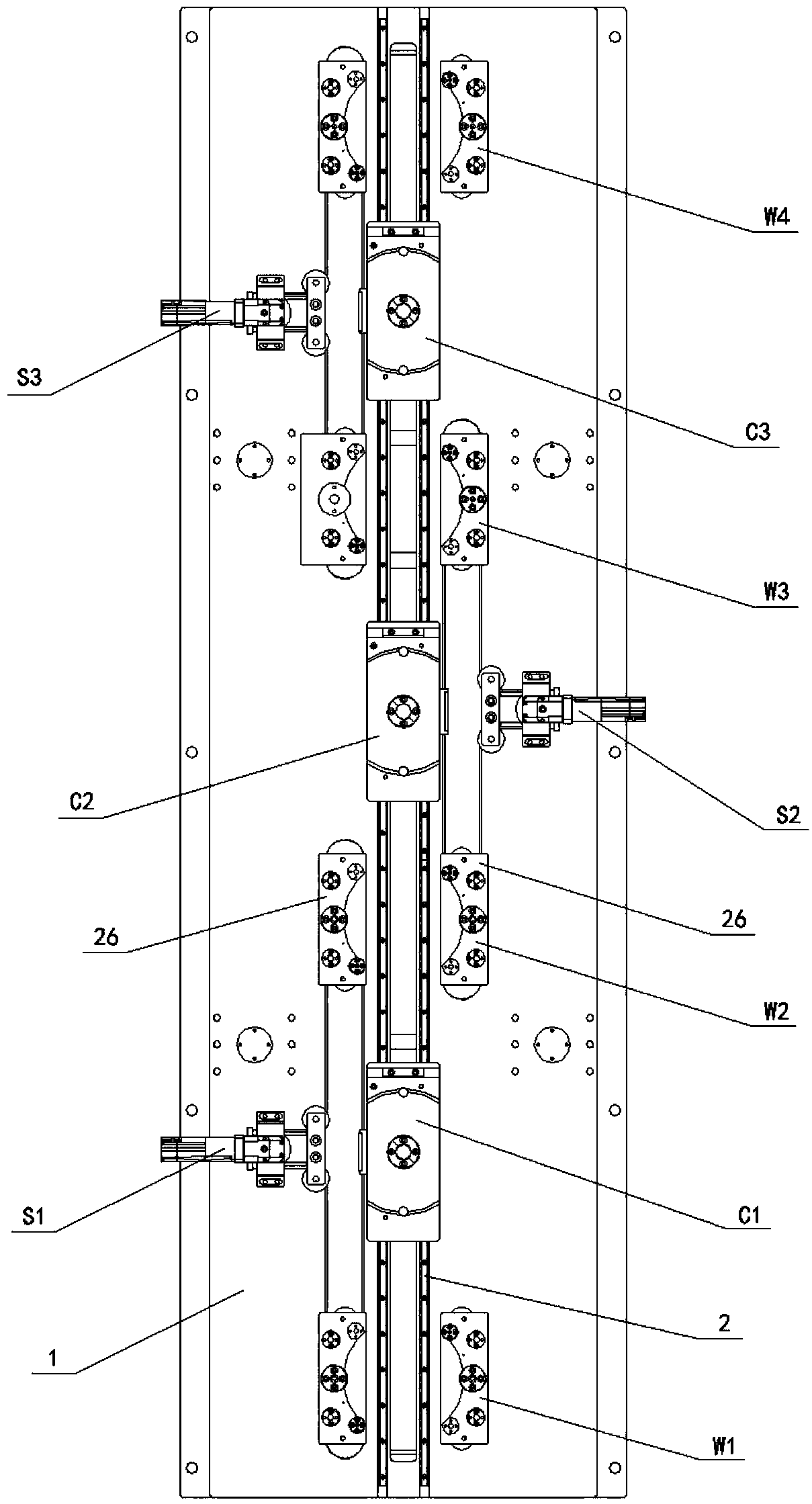

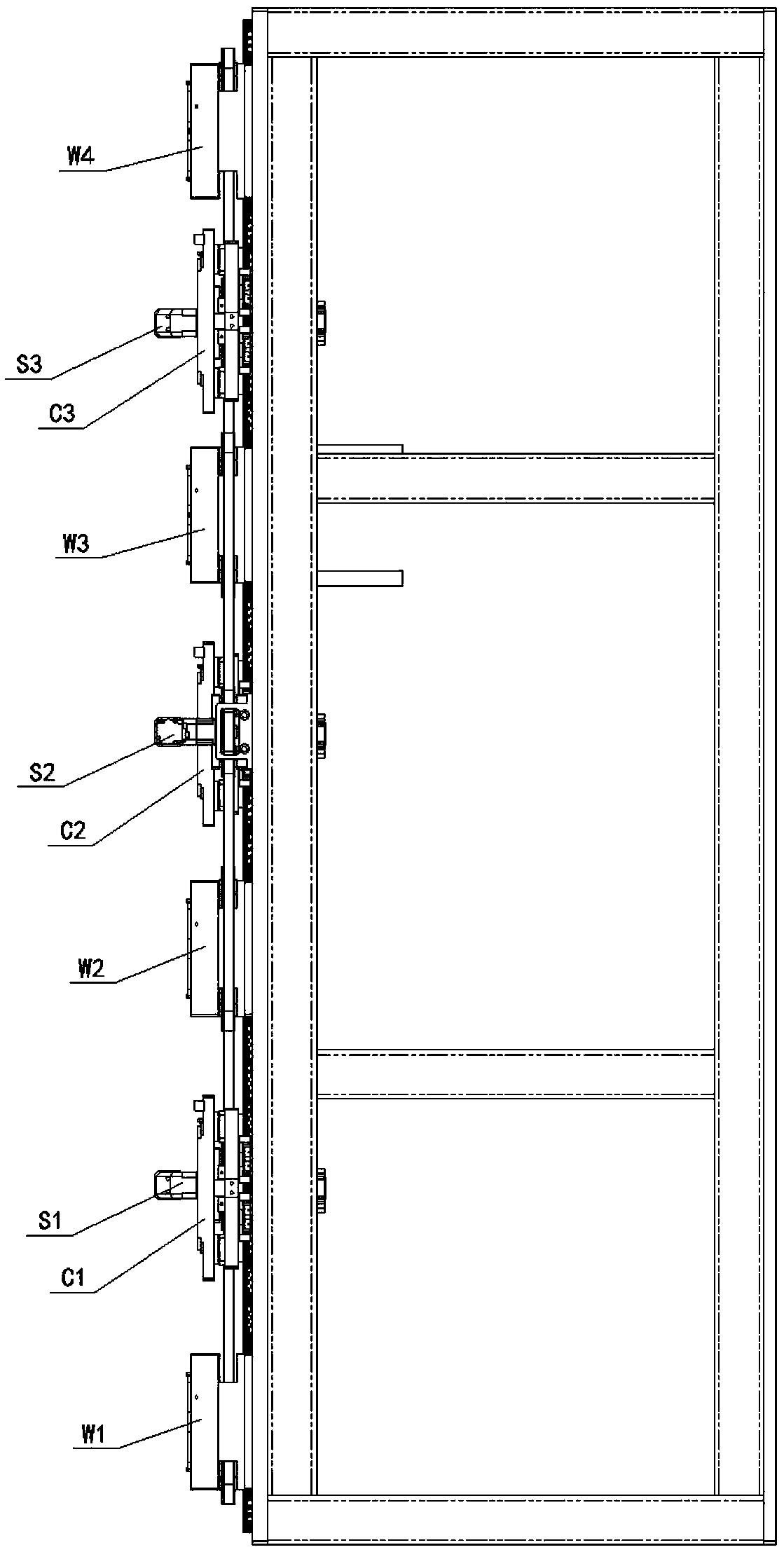

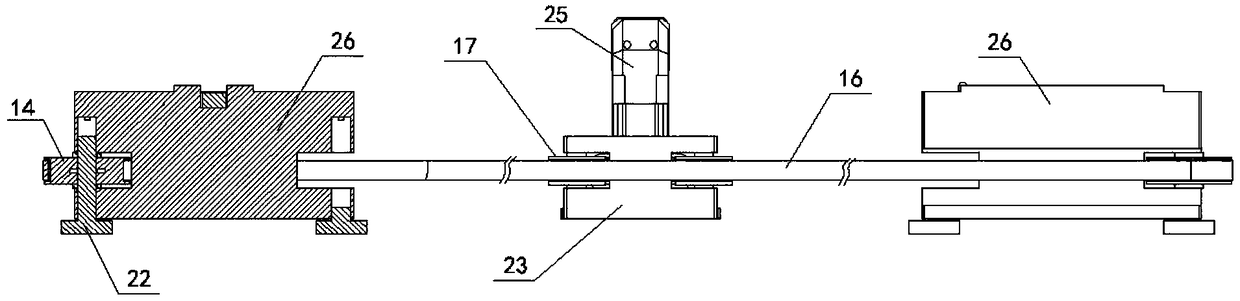

[0026] In this embodiment, the pallet trolley multi-station conveying system is: on the same system platform 1, each station is arranged in sequence according to the assembly process, figure 1 and figure 2 Each station shown on the same system platform 1 is the first station W1, the second station W2, the third station W3 and the fourth station W4; Between the positions, the reciprocating drive mechanism of the pallet trolley between the adjacent positions is independently set, figure 1 and figure 2 The pallet trolleys on the same system platform 1 shown are respectively the first trolley C1, the second trolley C2 and the third trolley C3, and the reciprocating drive mechanisms of each pallet trolley are the first drive mechanism S1, the second drive mechanism S2 and the third trolley respectively. Three-drive mechanism S3; the pallet trolley can not only travel forward from the previous station to the next station along the conveying direction of the system, but also reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com