Wire harness welding auxiliary tooling

A technology of auxiliary tooling and wire harness, which is applied in the direction of auxiliary devices, welding equipment, welding/welding/cutting items, etc. It can solve the problems of easy welding, random placement, and easy heating of joints, etc., so as to improve cutting efficiency and realize universal Sexuality, the effect of ensuring consistency

Inactive Publication Date: 2019-10-01

ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Articulation method: 1) The wiring harness connector after manual articulation is easy to loosen or even fall off, and the ability to withstand external forces is weak; 2) The current conduction area of the manual articulation joint is small, and the joint is prone to heat, which is dangerous; 3) When encountering a hard wire harness, Manual Articulation Difficulty

Soldering iron welding method: 1) The manual soldering iron and soldering process requires many times of practice, and welding is prone to false welding; 2) The shape of the joint after welding is inconsistent; 3) The temperature of the soldering iron is high, and it is placed randomly, which may cause the risk of burns

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

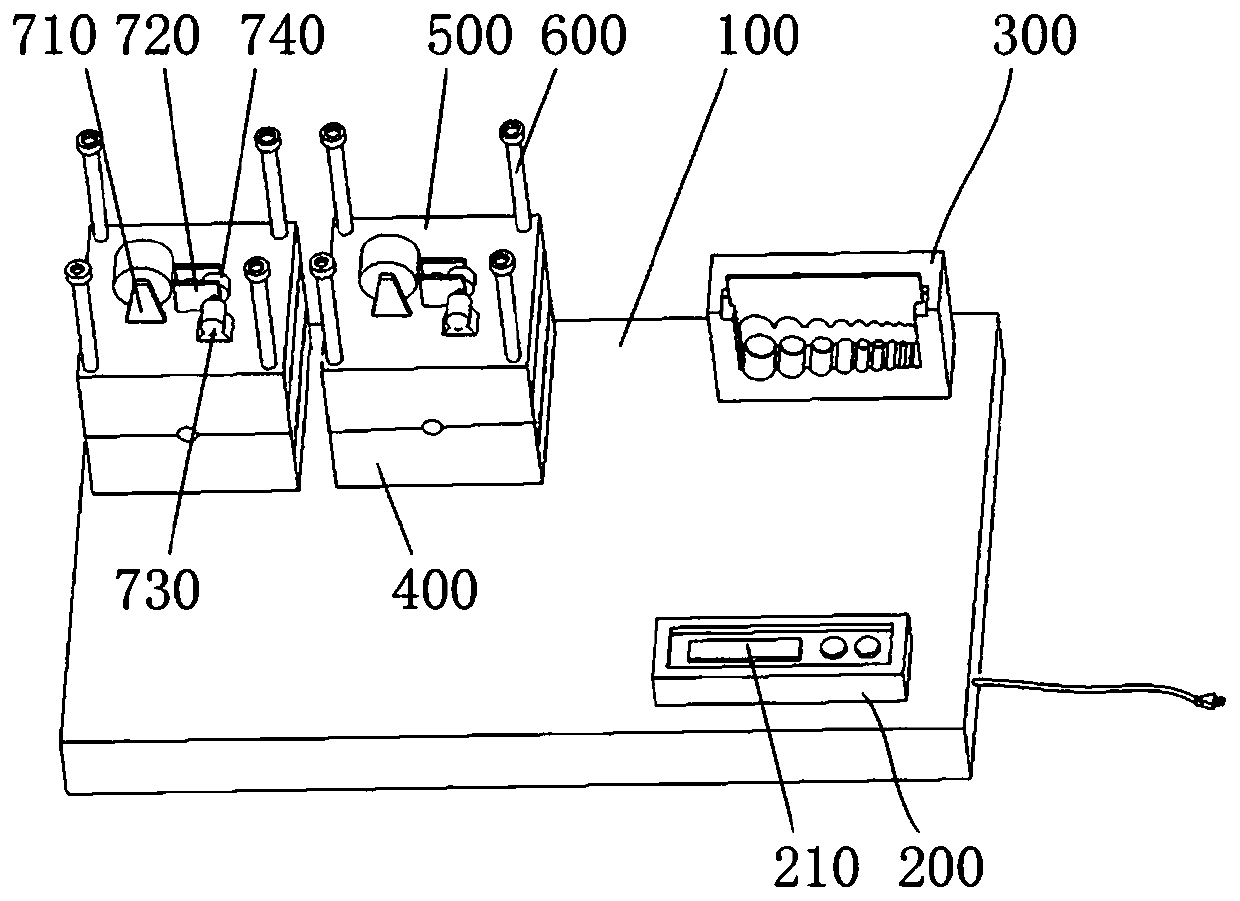

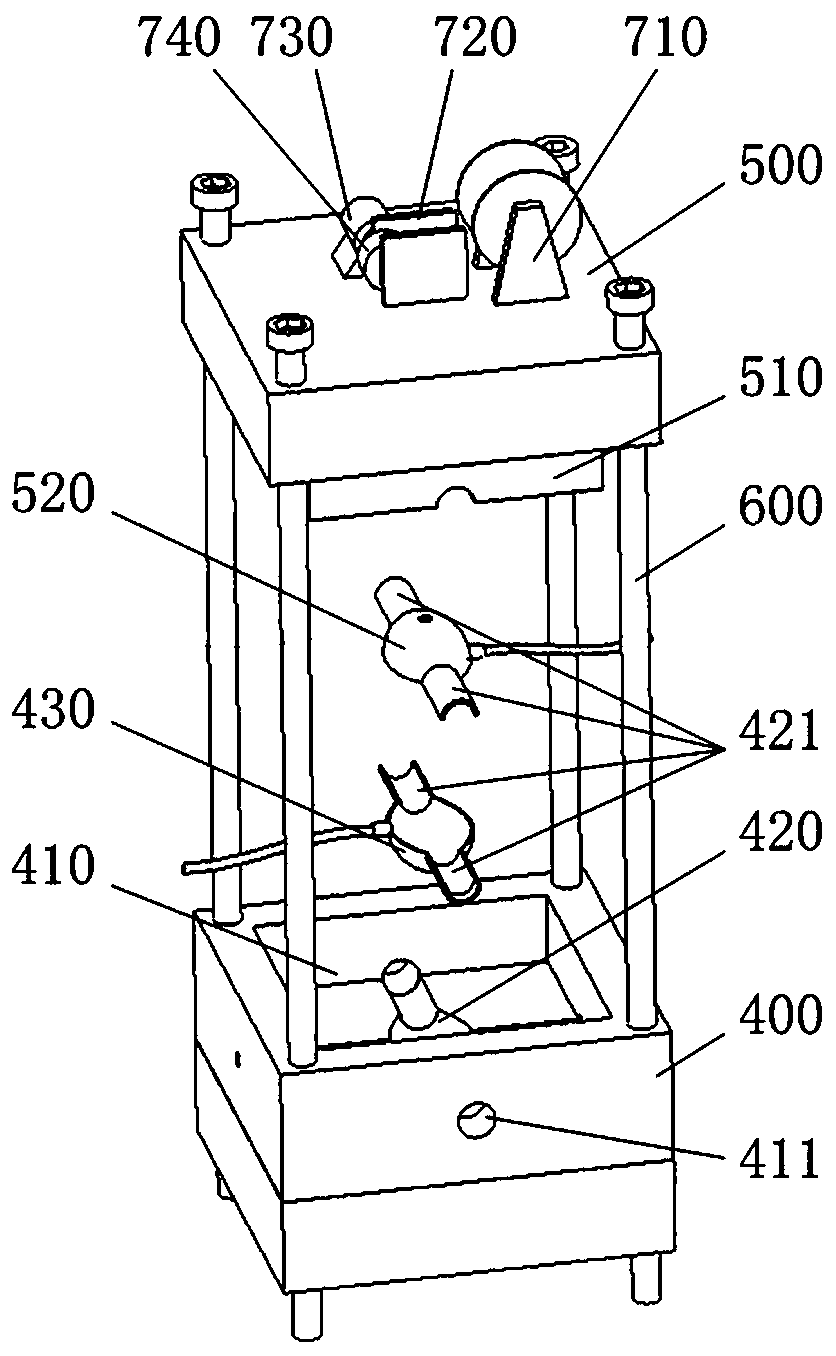

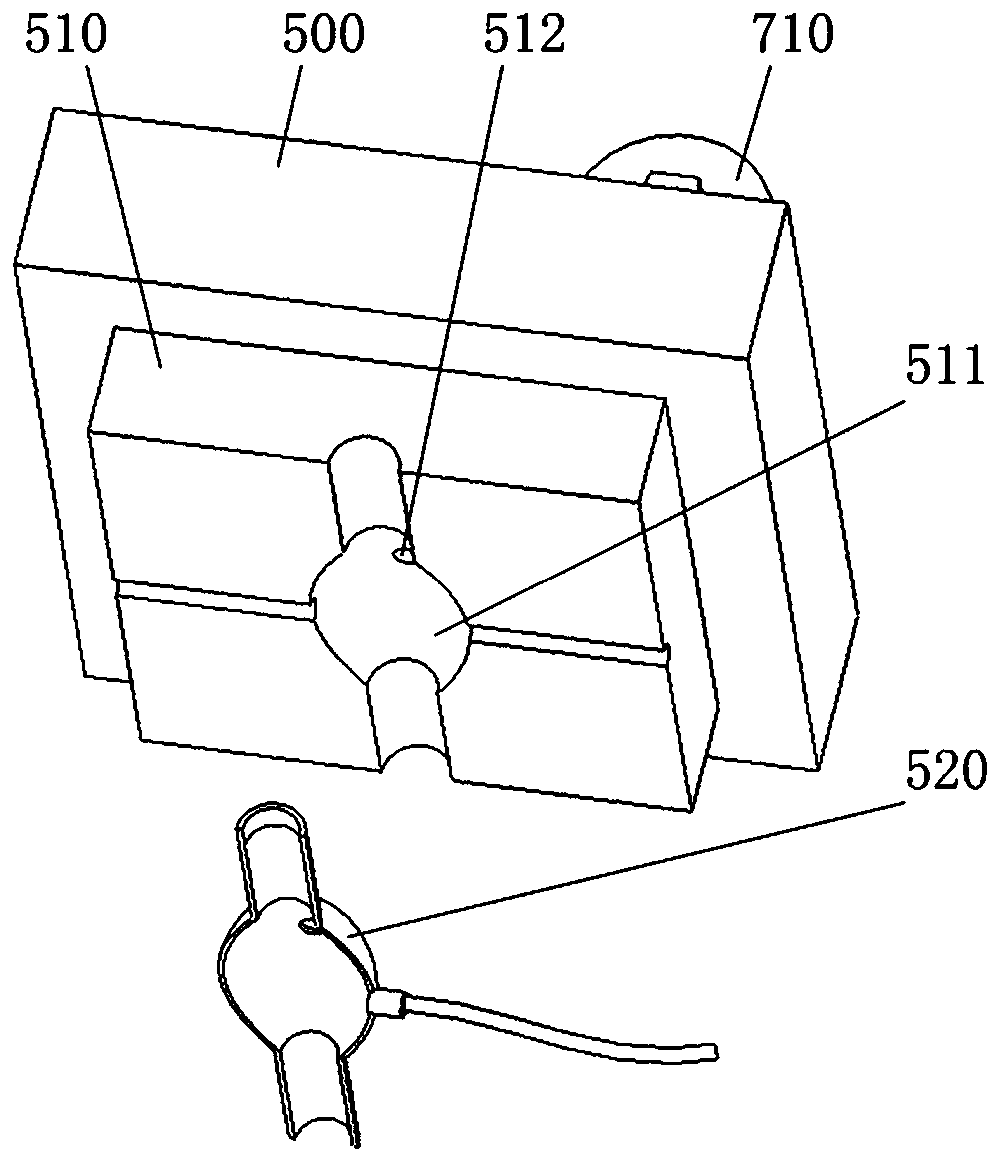

The invention discloses an auxiliary wire harness welding tool which comprises a base, a controller, an upper module, a lower module and a guide column, wherein the controller is fixedly arranged on the base; the lower module is fixedly arranged on the base; one end of the guide column is fixedly arranged in the lower module in a penetrating manner; the upper module is arranged on the guide column in a sliding and sleeving manner; an upper diaphragm is fixedly arranged on the upper module; a lower diaphragm matched with the upper diaphragm is fixedly arranged on the lower module; the upper diaphragm and the lower diaphragm are matched to form welding space; and the upper diaphragm and the lower diaphragm are electrically connected with the controller. According to the auxiliary wire harness welding tool, the controller is adopted to automatically control wire harness welding, so that consistency of welding positions and welding shapes of all groups of wire harnesses is ensured, and the cold solder joint problem is avoided; and in addition, during welding, an operator only needs to operate the controller without needing being close to the welding wire harness, so that the operator is prevented from the scald risk.

Description

technical field The invention relates to a wiring harness connection mechanism, in particular to a wiring harness welding auxiliary tool. Background technique In daily life or work, it is often encountered that two or more power supply wire harnesses and signal wire harnesses are connected together. The commonly used connection methods are: hinged and welded. Simple hinge can be done by hand, common soldering iron, solder and rosin can be used for common welding. For the connection of wire harnesses in daily work and life, the commonly used hinges and welding have the following disadvantages: Articulation method: 1) The wiring harness connector after manual articulation is easy to loosen or even fall off, and the ability to withstand external forces is weak; 2) The current conduction area of the manual articulation joint is small, and the joint is prone to heat, which is dangerous; 3) When encountering a hard wire harness, Manual articulation is difficult. Soldering ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K3/06B23K3/08B23K101/32

Inventor 谢飞飞李英涛宋长青王善强张申祥张敬东郭强强张大晴

Owner ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com