Method and device for prediction of maintenance time

A maintenance time, scheduled maintenance technology, applied in the direction of calculation, instrumentation, data processing applications, etc., can solve the problem of reflecting the detailed information of maintenance time design and maintenance operation process of newly developed products, waste of manpower and material resources, lagging discount, etc. problems, to achieve the expected results effective and accurate, reduce material and labor costs, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

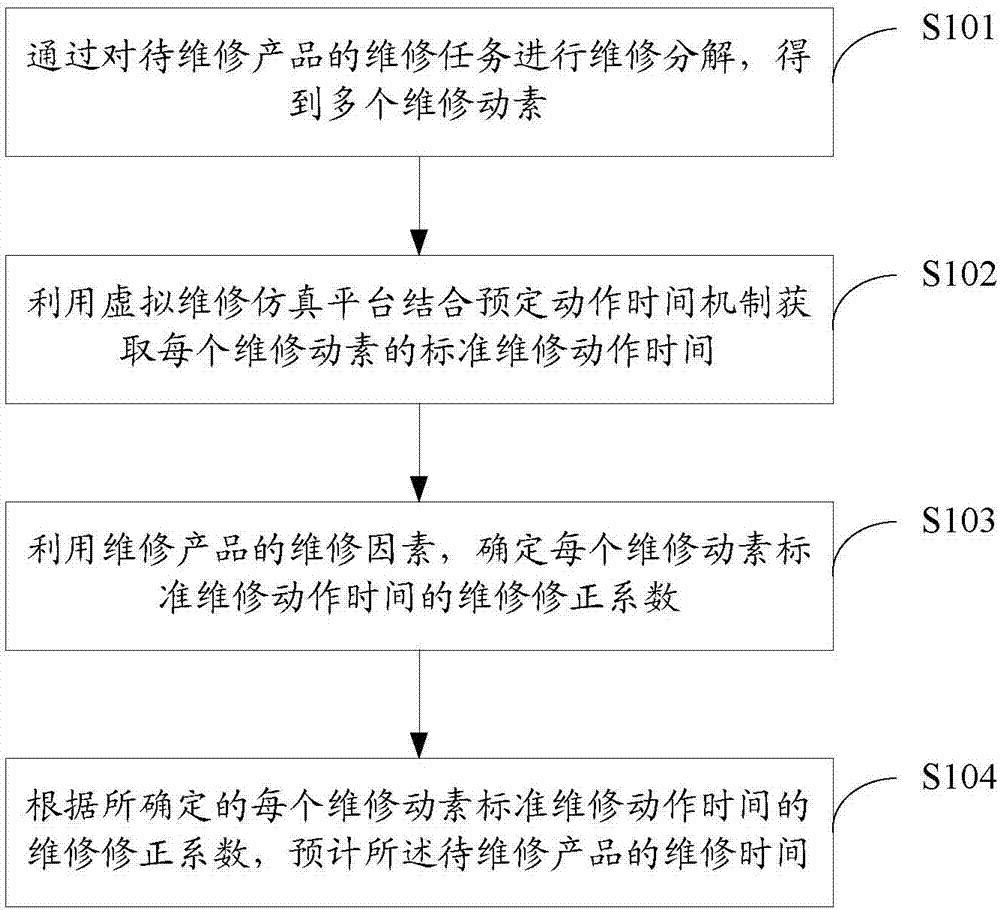

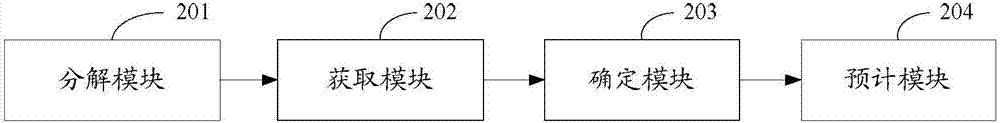

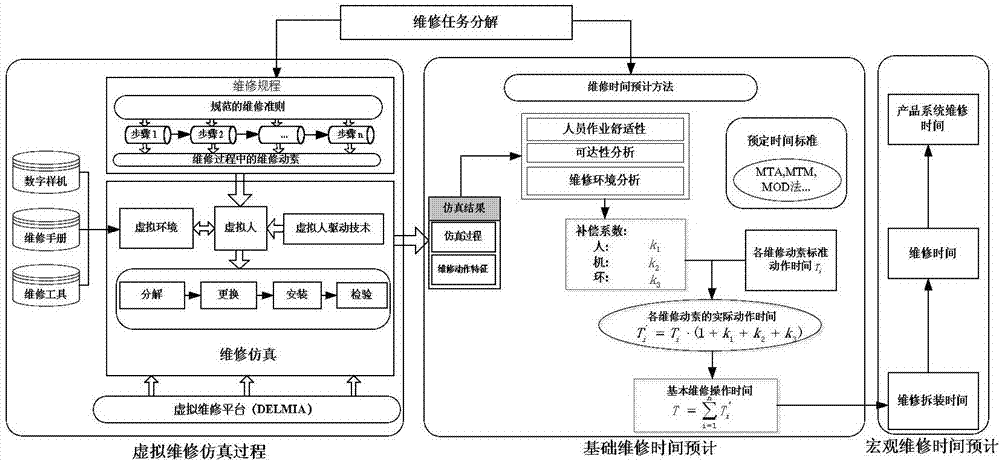

Method used

Image

Examples

Embodiment

[0118] Take the APU (Accelerated Processing Unit, accelerated processor) disassembly process of a passenger aircraft as an example. The APU is installed on the tail wing of the aircraft and is fixed on the bracket by 8 hex head screws. According to the decomposition of maintenance factors in step 1, and the actual maintenance procedures, the simulation and evaluation of the maintenance process in the virtual environment are completed, and the maintenance time is estimated by the MOD method (model method) in the scheduled operation time method as an example. It is assumed that the maintenance task is carried out at the airport in Beijing in winter night. The main steps of APU disassembly are as follows.

[0119] A. Go to the working platform of the support equipment and approach the maintenance target.

[0120] B. Open the 7 hatches

[0121] C. Open the left hatch

[0122] D. Open the right door

[0123] E. Remove the electrical connector

[0124] F. Remove 8 hex head screws

[0125] G....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com