Model surface friction measuring device

A technology for measuring devices and models, applied in the directions of measuring devices, surface/boundary effects, instruments, etc., can solve problems such as inability to offset interference, and achieve the effects of ensuring measurement sensitivity, improving accuracy, and reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The technical solutions of the present invention will be described in more detail below in conjunction with the accompanying drawings.

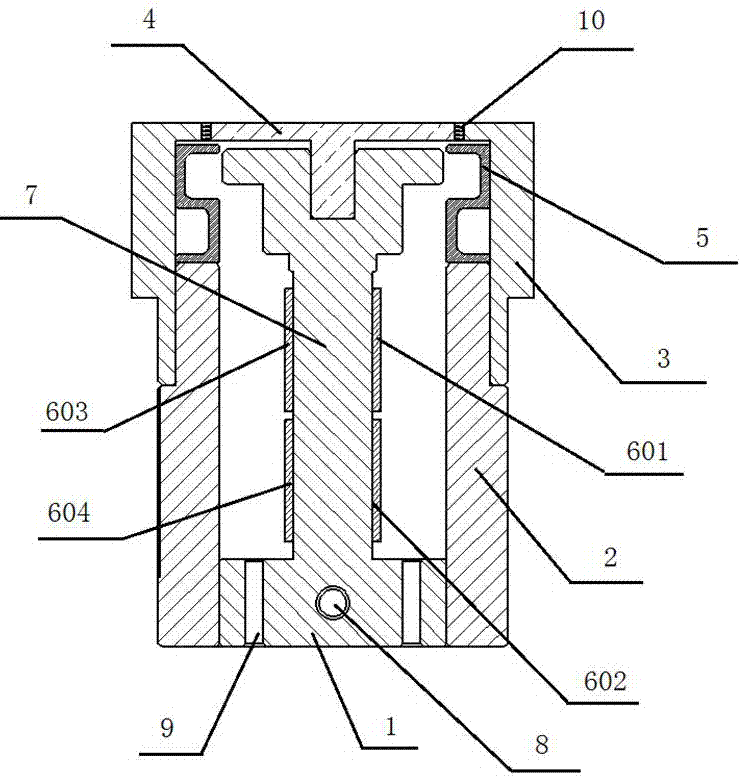

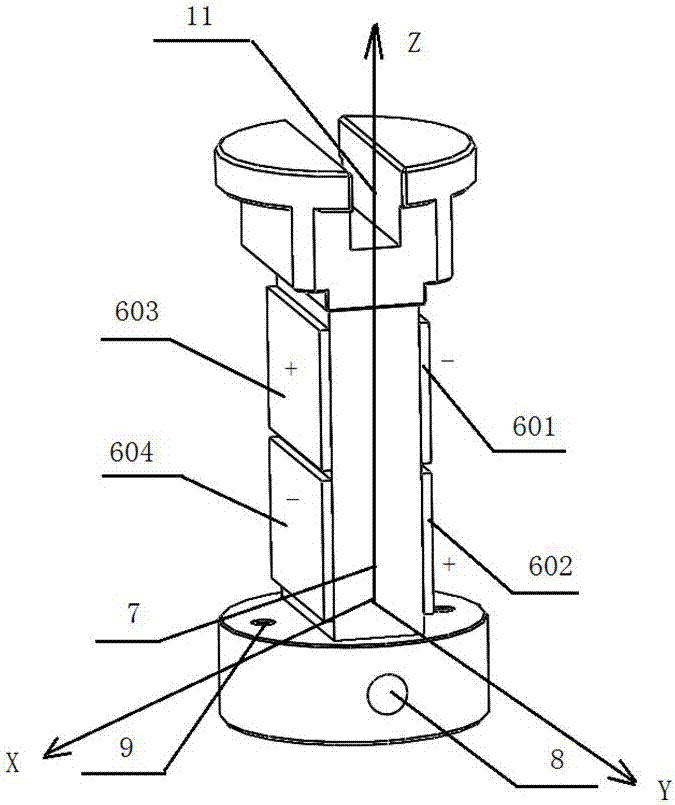

[0031] Such as figure 1 As shown, the model surface friction measuring device of the present invention includes: a friction balance body 1 , a measuring head 4 , a piezoelectric sheet 6 , a protective cover base 2 , a protective cover upper cover 3 and a heat insulating retaining ring 5 .

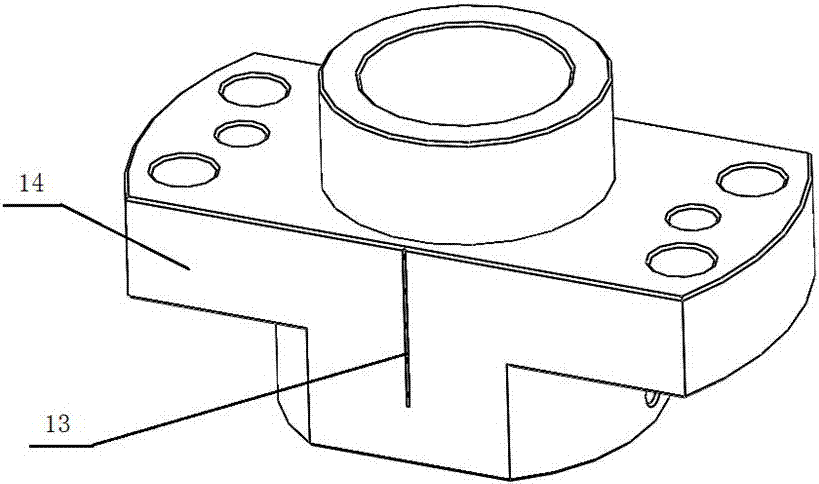

[0032] The friction balance body 1 is composed of a base 12 and a force-sensitive beam 7. The base 12 is provided with a pin hole 8 connected to the protective cover base 2 and a lead hole 9 for leading the signal line out of the model surface friction measurement device. 6 is pasted on both sides of the force-sensitive beam 7, and a measuring head installation groove 11 is provided on the head of the friction balance body 1.

[0033] The measuring head 4 is installed in the measuring head installation groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com