Bulletproof structure and automobile

A technology of bulletproof plate and main bulletproof plate, applied in the direction of motor vehicles, protective equipment, armored vehicles, etc., can solve the problems such as failure to reach the protection index, the protection performance of the bulletproof plate is reduced, the heat affected zone is large, etc., and the metallographic change range can be achieved. Small, reinforced anti-ballistic performance is reduced, and the effect of low heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

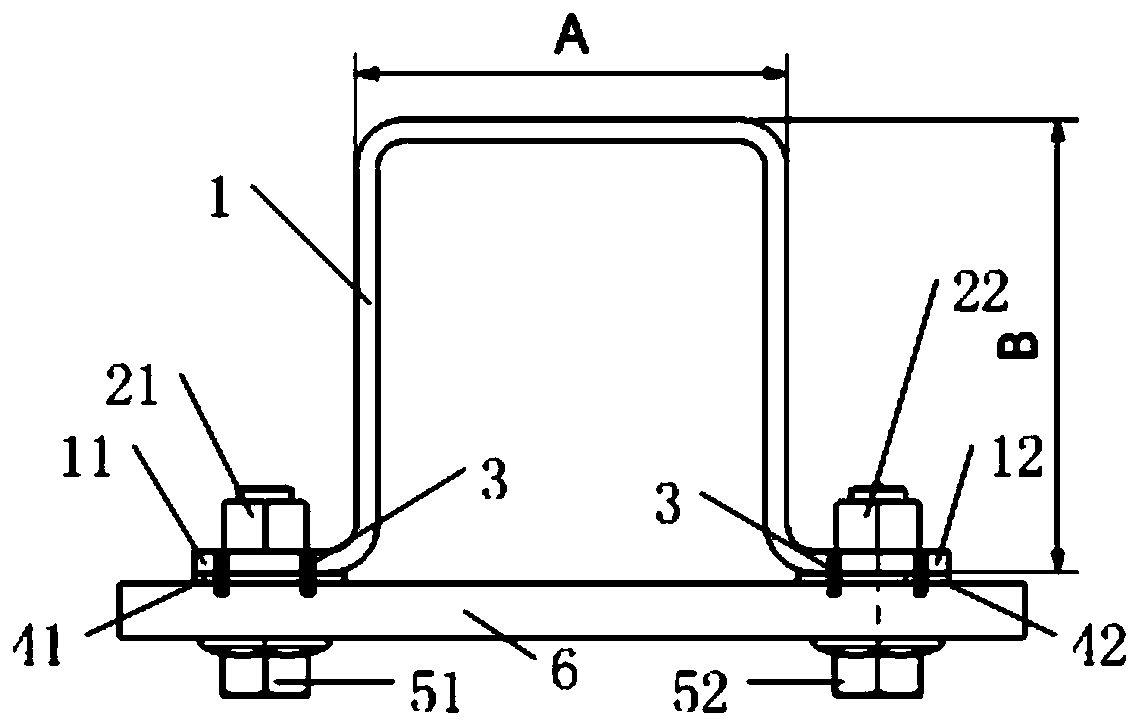

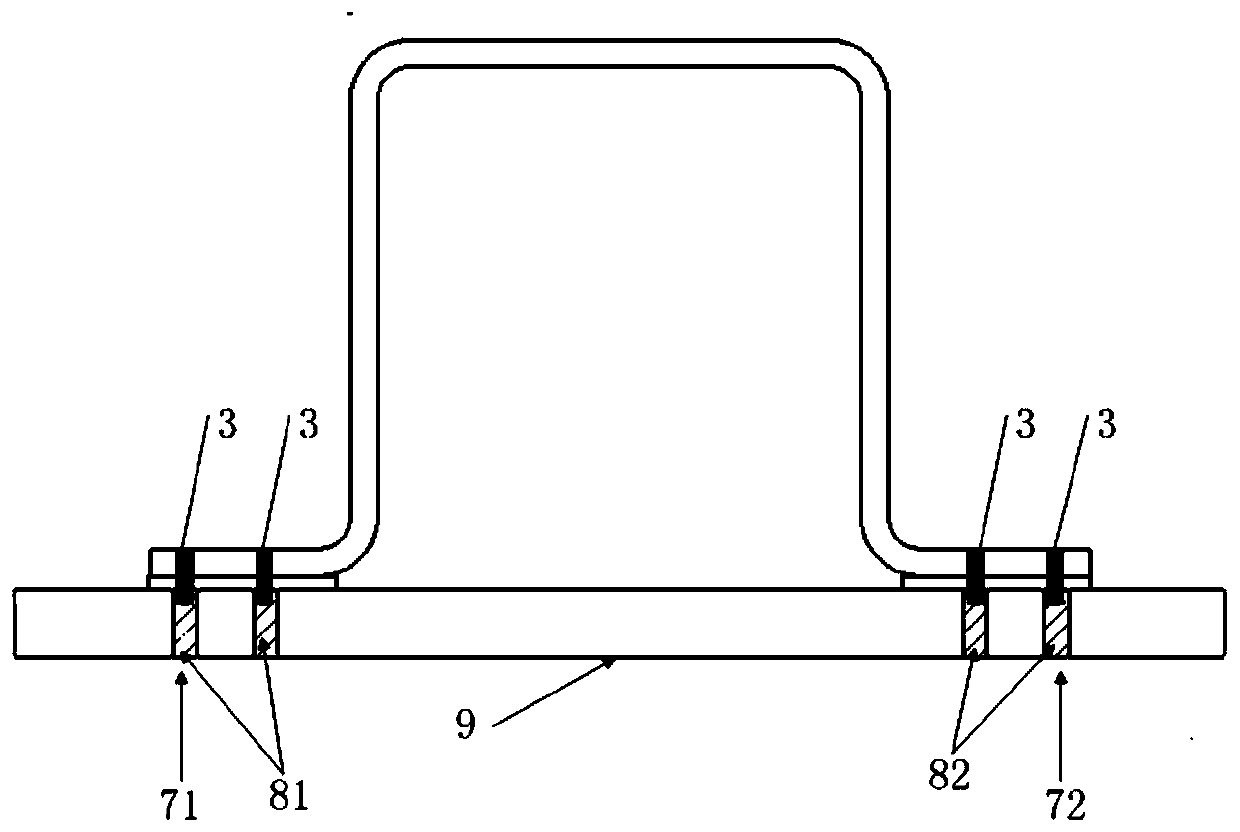

[0031] see figure 1 , an embodiment of the present invention provides a bulletproof structure, comprising:

[0032] The main bulletproof plate 6 and the bulletproof plate skeleton 1; wherein, the bulletproof plate skeleton 1 is a “Ji”-shaped structure.

[0033] In a specific embodiment of the present invention, the bulletproof plate frame 1 has a first installation part 11 and a second installation part 12, which provide a good welding overlap form for laser welding and make laser welding simpler and easier.

[0034] Preferably, a first low carbon steel welding strip 41 is provided between the main bulletproof plate 6 and the first installation part 11;

[0035] A second low-carbon steel welding strip 42 is provided between the main bulletproof plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com