Pre-embedded type supporting base of cable bracket and mounting method for pre-embedded type supporting base

A cable support, pre-embedded technology, applied in the direction of pipeline support, mechanical equipment, pipe/pipe joint/pipe fittings, etc., can solve the problem that the support and the concrete are not on the same plane, the height of the support is not easy to adjust, and the quality of the concrete is not good. problems, to achieve the effect of improving construction quality, improving installation quality, and professional installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

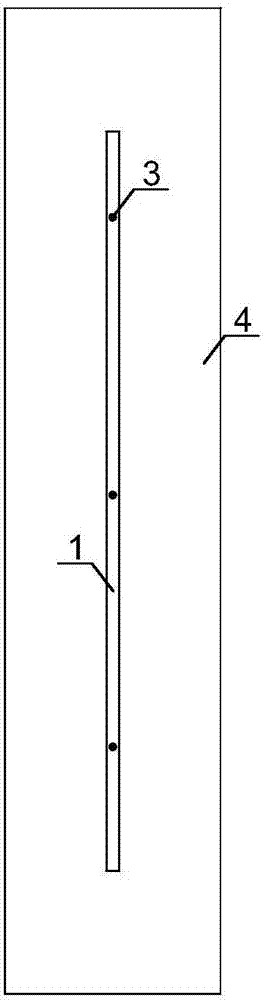

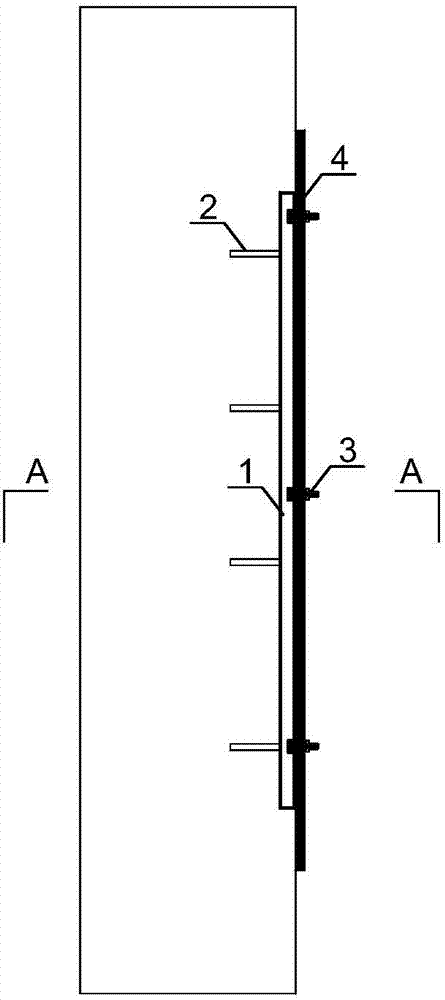

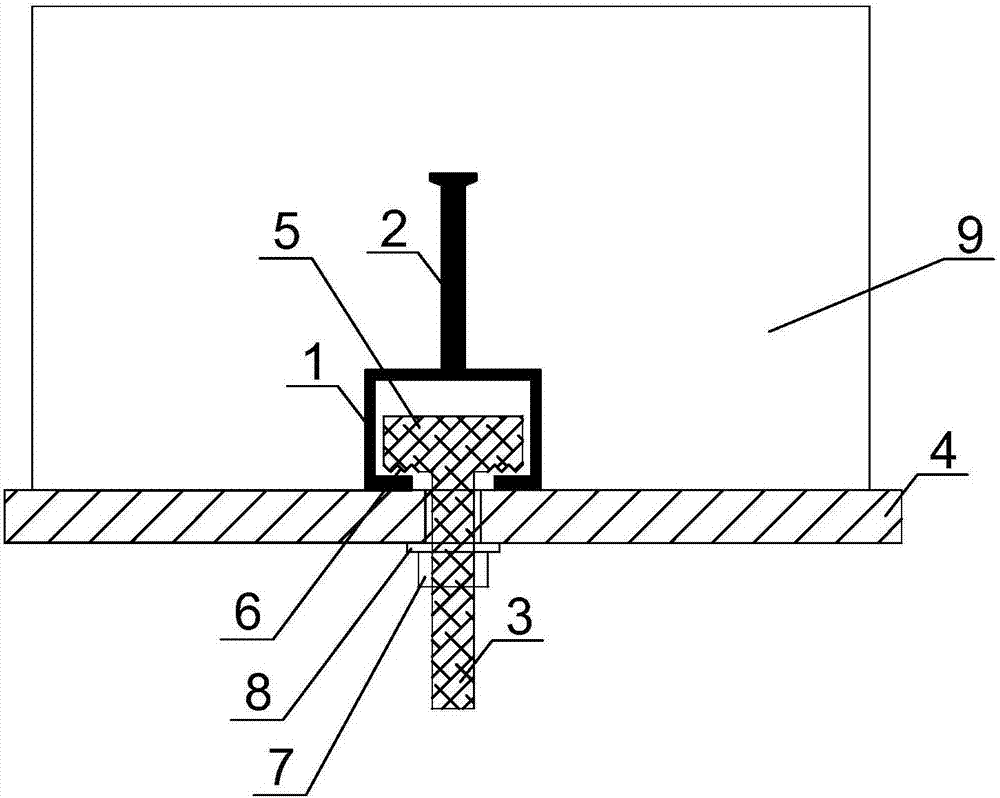

[0025] Such as Figure 1-3 As shown, the pre-embedded support of the cable support of the present invention includes a C-shaped steel 1, and the opening side of the C-shaped steel 1 is provided with a bolt 3, and the bolt 3 is preferably a T-shaped bolt, such as an M10 bolt. The nut 5 at one end of the bolt 3 is arranged on the inner side of the C-shaped steel 1; on the outer wall of the other side of the C-shaped steel 1 opposite to the opening side, a pre-embedded reinforcement 2 is arranged; the opening of the C-shaped steel 1 A template 4 is also provided on the side. Among them, the C-shaped steel 1 is preferably Q235 steel. The addition of formwork 4 makes it possible to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com