A suspension structure of a powertrain

A powertrain and suspension technology, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of easy disengagement of connecting bolts and elastic elements, easy to rotate with the nut, and to rotate with the nut, etc. Achieve the effect of increasing size, avoiding self-rotation, and eliminating additional torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

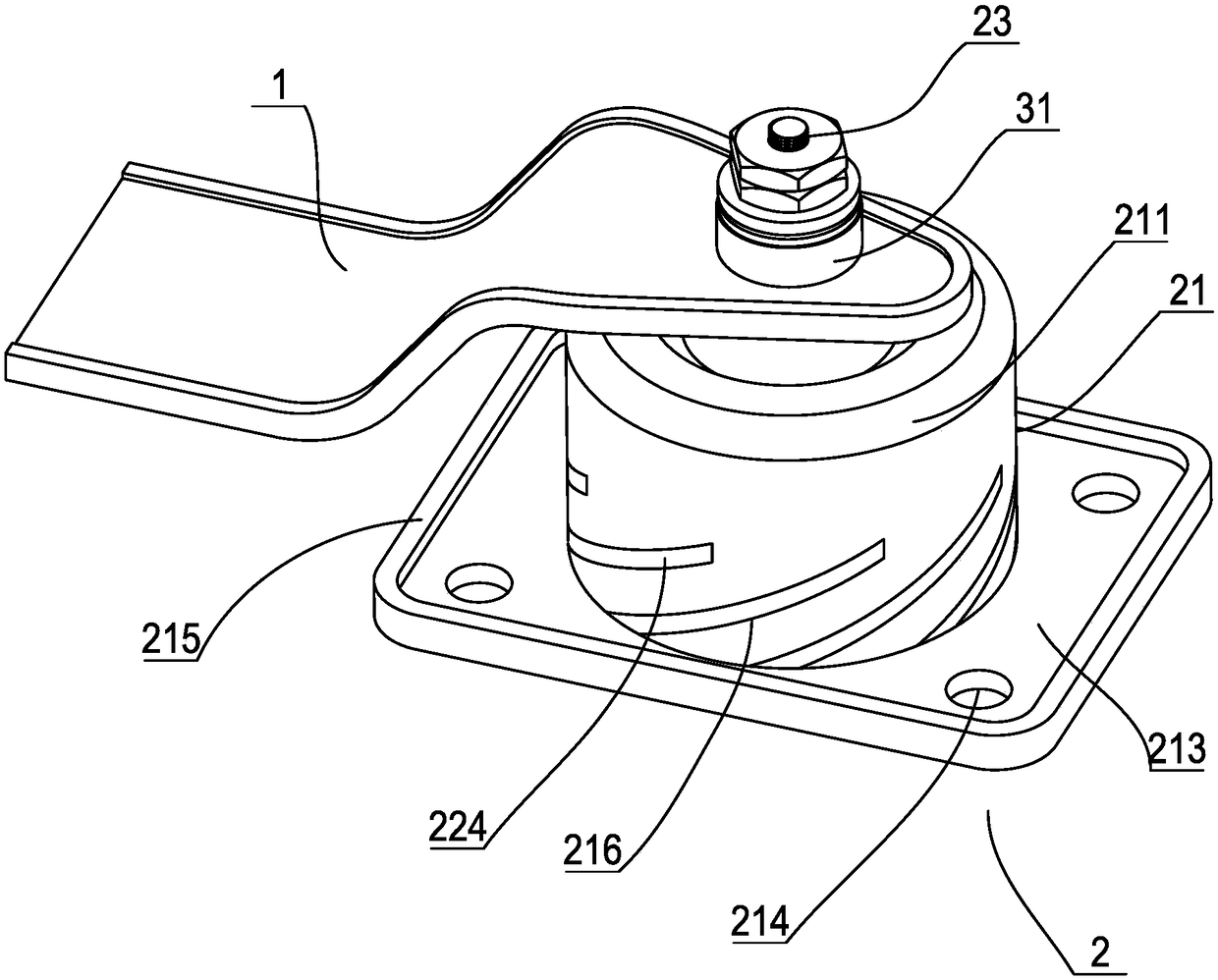

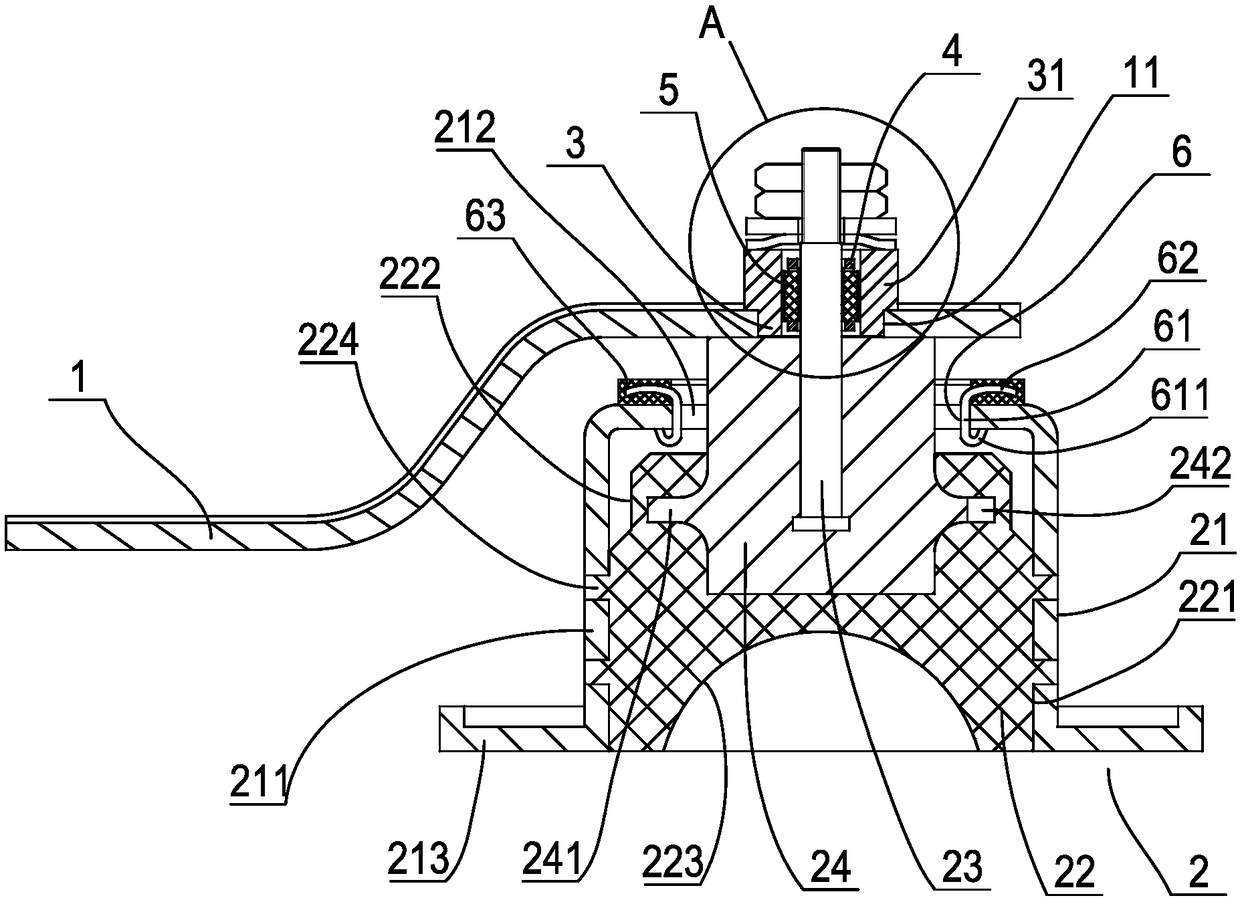

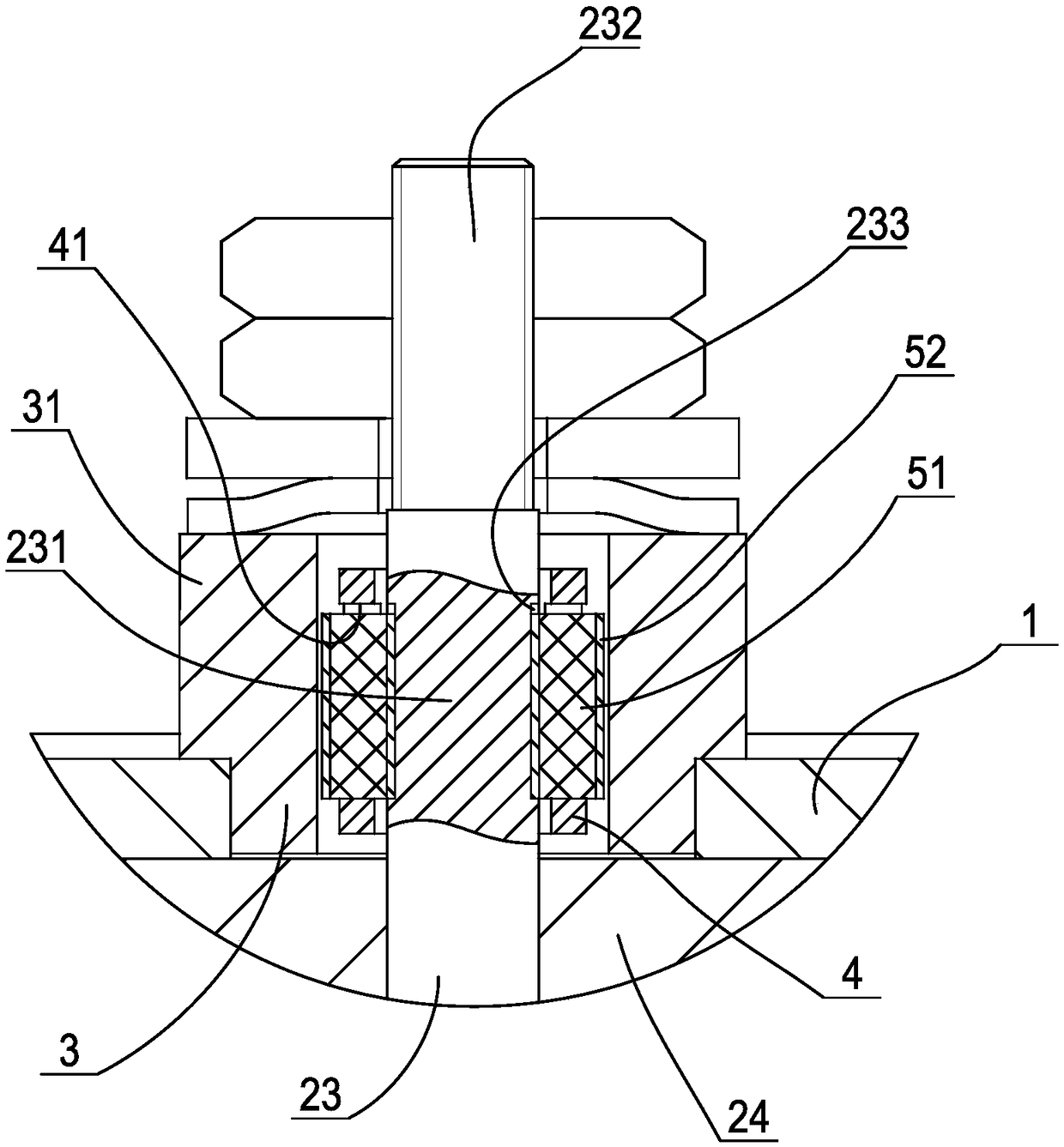

[0026] Such as figure 1 , figure 2 As shown, a suspension structure of a power assembly includes a suspension bracket 1 connected to the power assembly at one end, a suspension spring 2 arranged on the vehicle frame, the suspension spring includes a fixed casing 21, and is arranged on the fixed casing. Inside is an elastic element 22 made of rubber, and a connecting bolt 23 connected with the elastic element. The fixed shell includes a cylindrical protective shell 211, the lower end of which has an opening, and the elastic element is arranged in the protective shell. A connecting bolt through hole 212 is provided on the bottom wall of the upper part of the protective shell, and the upper end of the connecting bolt passes through the connecting bolt through hole upwards, and a rectangular mounting bottom plate 213 extending radially along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com