Novel white sidewall extrusion device

A technology of extrusion device and white sidewall, which is applied in the field of tire production, can solve the problems of affecting the flexibility of the sidewall, adversely affecting the quality stability of the white sidewall, and easily polluting the sidewall rubber, etc., and achieves the effect of facilitating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

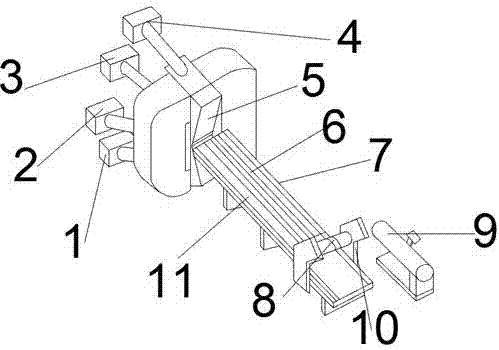

[0010] Such as figure 1 As shown, a new type of white sidewall extrusion device, including Ф150 screw 1, Ф200 screw 2, Ф90 screw 3, Ф120 screw 4, a new type of white sidewall extrusion line head 5, extruded white sidewall rubber 6, New white sidewall extrusion line auxiliary line 7, cover film 8, Ф90 screw extruder 9, small double two-roller extruder 10, conveyor belt 11, Ф150 screw 1, Ф200 screw 2, Ф90 screw 3 and Ф120 screw 4 Connect the head 5 of the new white sidewall extrusion line smoothly through the pipeline from bottom to top. The two sides of the conveyor belt 11 are paved with the auxiliary line 7 of the new white sidewall extrusion line. The extruded white sidewall rubber 6 is paved on the transmission At the central position of the belt 11, the cover film 8 is installed on the rotating shaft of the small double two-roller extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com