Optical fiber grating-based surrounding rock internal strain monitoring method

A fiber grating and strain monitoring technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor shear resistance and achieve the effects of poor shear resistance, accuracy, and survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] combined with Figure 1-3 An example of the device is described in detail as follows:

[0018] A method for monitoring internal strain of surrounding rock with optical fiber gratings, using a bare optical fiber grating pre-tensioning device to monitor the internal strain change of surrounding rock, so as to realize the monitoring of internal deformation characteristics and damage mechanism of surrounding rock.

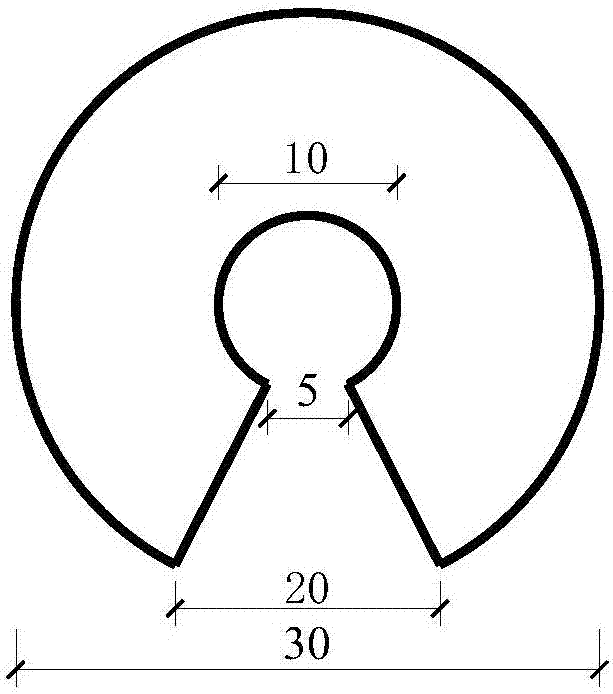

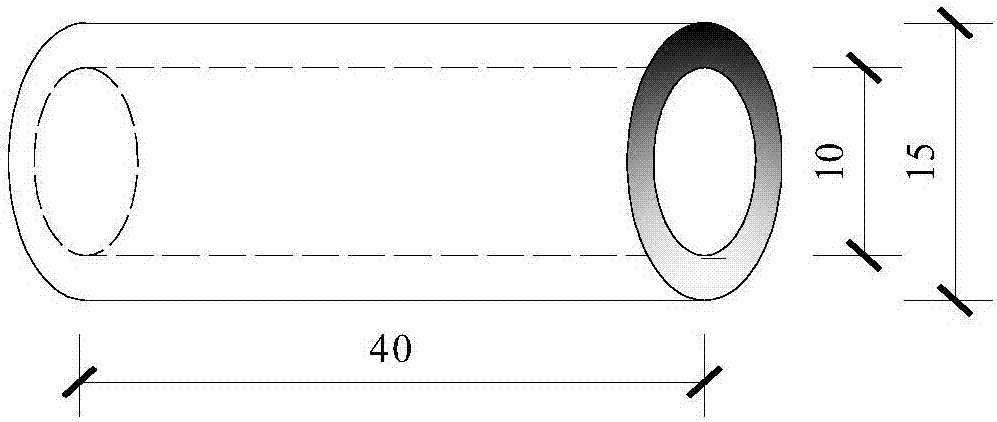

[0019] The fiber grating pre-tensioning device includes a bare fiber grating sensor 1, a U-shaped stainless steel specimen 2, a metal gasket 5 and a packaged steel pipe 4;

[0020] A round hole is opened on the U-shaped frame at both ends of the U-shaped stainless steel test piece 2, and the two ends of the bare fiber grating sensor 1 are penetrated through the round hole, and the outer surface of the U-shaped frame is abutted with a packaged steel pipe 4, and the packaged steel tube 4 is sealed with a packaging glue 3. It is socketed on the bare fiber grating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com